rotating electrical machine

A technology for rotating electrical machines and rotors, applied in the field of rotating electrical machines, can solve the problems of insufficient cooling of permanent magnets, complex shapes of casings, and complex shapes of rotor shafts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

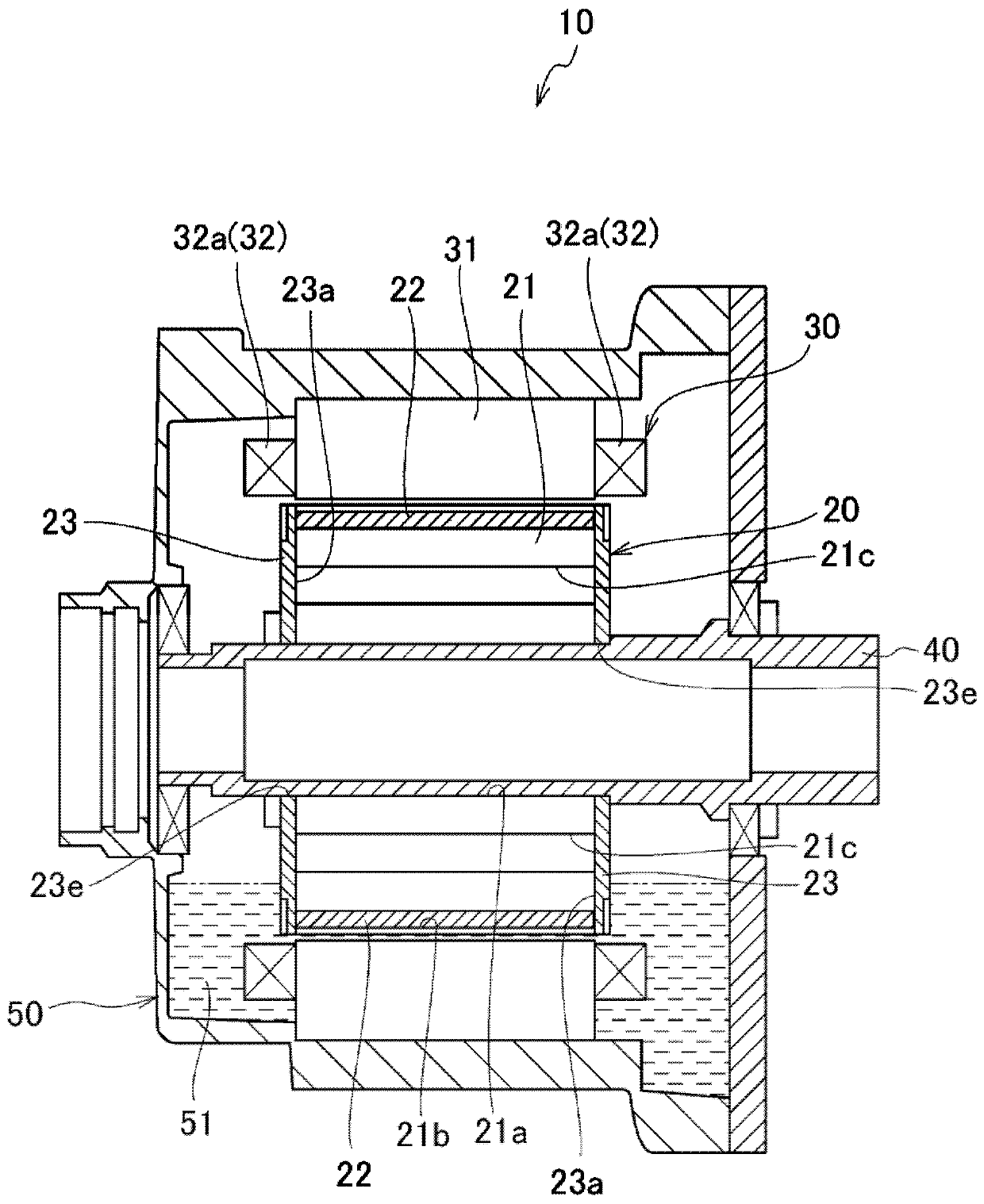

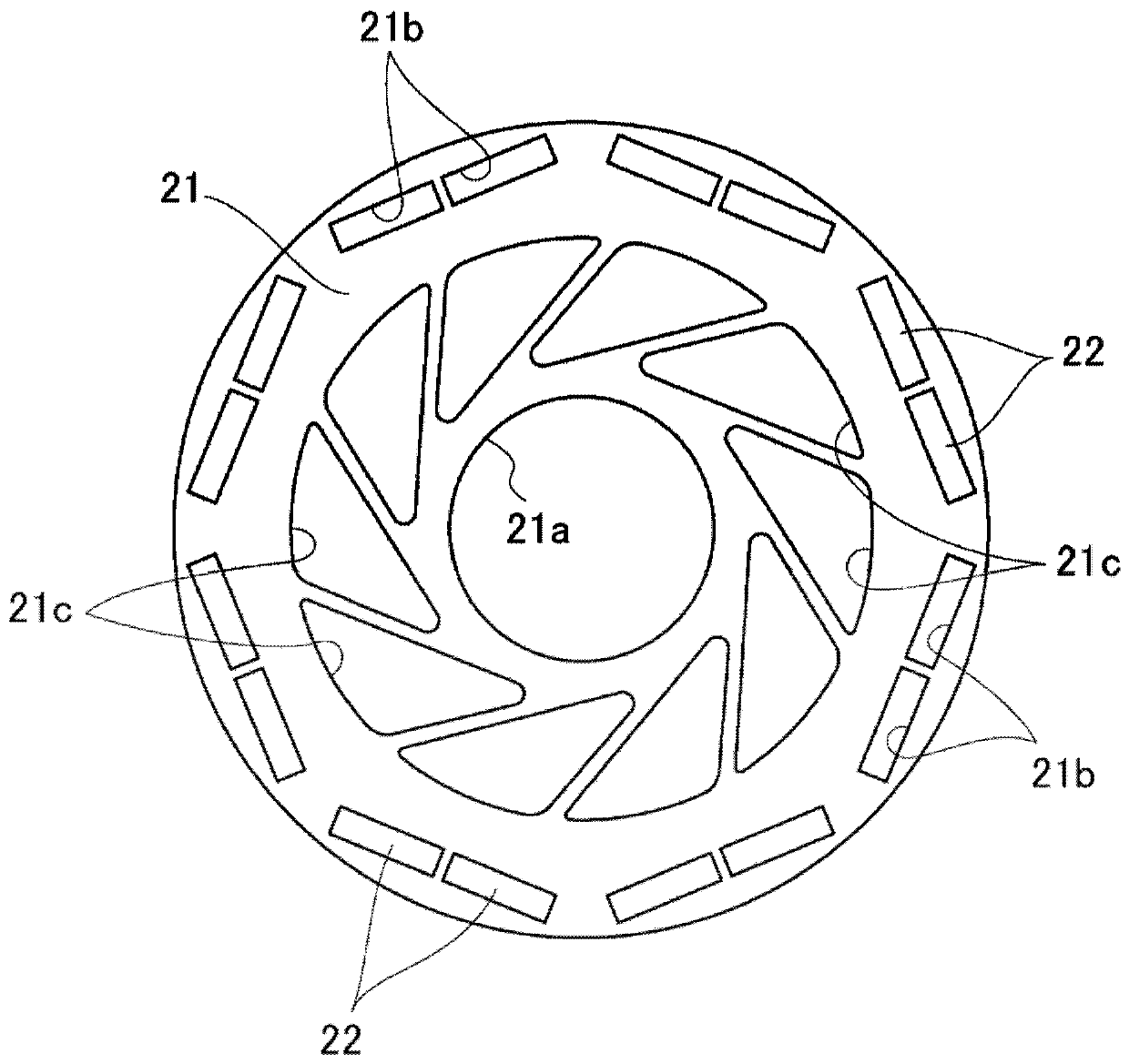

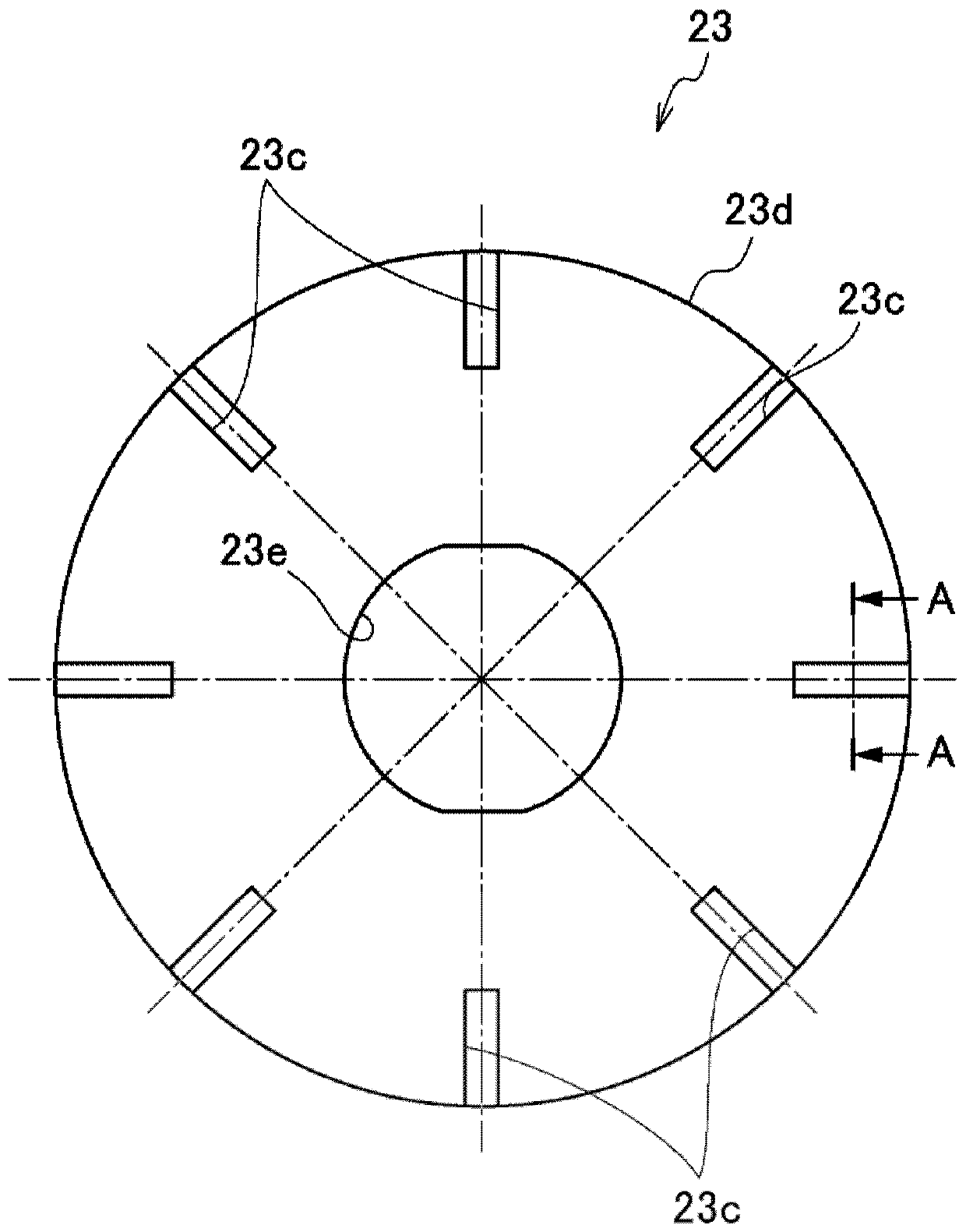

[0074] Below, according to Figures 1 to 5A and Figure 5B , an embodiment of the rotating electrical machine of the present invention will be described. In addition, the drawings are viewed along the direction of the symbols.

[0075] [rotating motor]

[0076] Such as figure 1 As shown, the rotating electric machine 10 according to the present embodiment is a so-called inner rotor type rotating electric machine, which includes a rotor 20, a stator 30 disposed opposite to the outer peripheral side of the rotor 20 with a slight gap therebetween, and is integrated with the rotor 20. A rotor shaft 40 is rotatably attached to the inner peripheral portion of the rotor 20 , and a housing 50 that accommodates the rotor 20 and the stator 30 and supports the rotor shaft 40 rotatably.

[0077] [case]

[0078] The housing 50 has a substantially cylindrical shape, and the stator 30 is fixed to the inner peripheral portion. The lower part of the housing 50 becomes a storage part 51 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com