Herbarium even drying box

A technology of plant specimens and drying boxes, which is applied in the direction of drying solid materials, drying chambers/containers, non-progressive dryers, etc., can solve the problems of uneven drying and low utilization rate of heat energy, etc., to improve the utilization rate of heat energy, Reduce the thickness and avoid the effect of falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

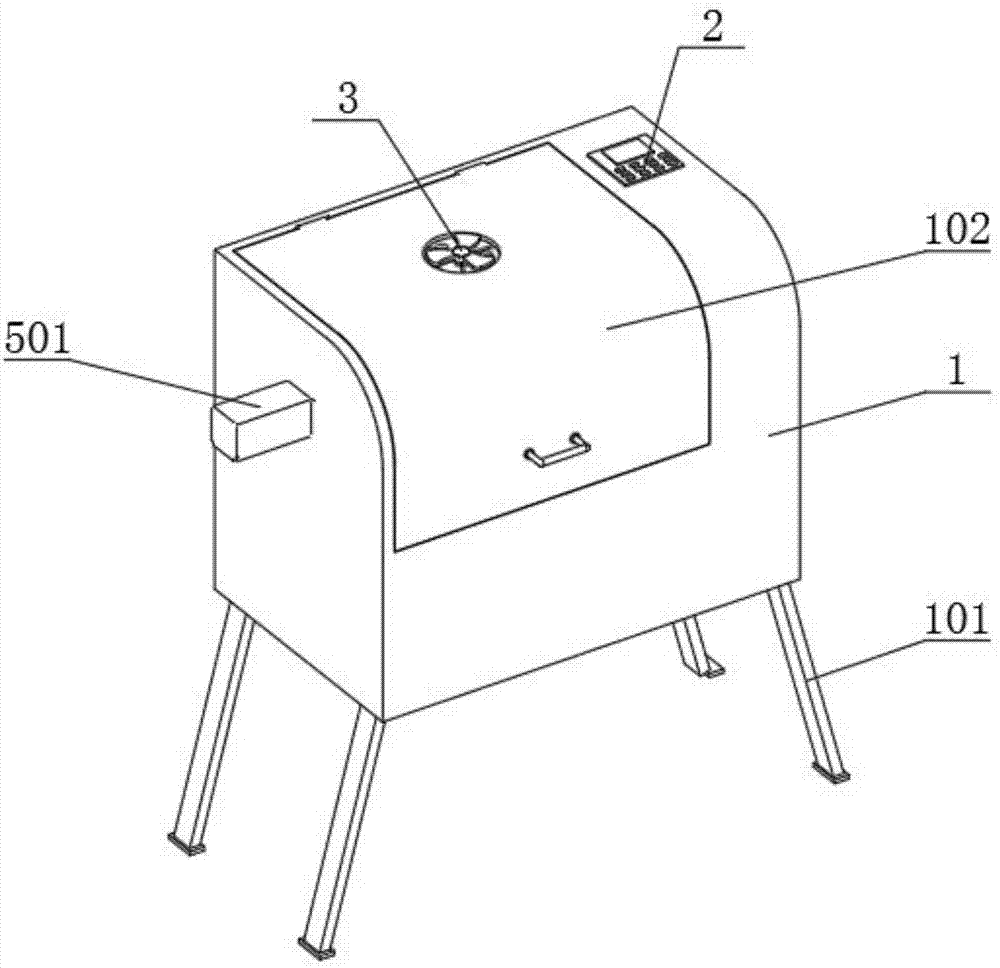

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The invention provides a uniform drying box for plant specimens, comprising a box body 1, a bracket 101, a box cover 102, a drying chamber 103, an air vent 104, a PLC controller 2, a dehumidification fan 3, a specimen holder 4, a first splint 401, Spring 402, second splint 403, non-woven fabric 404, moisture-absorbing paper 405, specimen 406, through hole 407, fixed rotating mechanism 5, motor 501, rotating shaft 502, bearing 503, beam 504, chuck 505, fixed block 506, clip Tighten the bolt 507, the temperature sensor 6 and the infrared lamp 7; the bottom of the box body 1 is fixedly supported with a bracket 101; the inside of the box body 1 is provided with a drying chamber 103, and a box cover 102 is hinged on the top of the drying room 103 The back side of the drying chamber 103 is provided with a vent 104; the cover 102 is equipped with a dehumidification fan 3; the PLC controller 2 is installed on the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com