Oil hot air furnace with intelligent control terminal

An intelligent control, hot blast stove technology, used in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of starting and stopping the boiler burner, no stable transition process, increasing the volume of the boiler control system, etc. achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

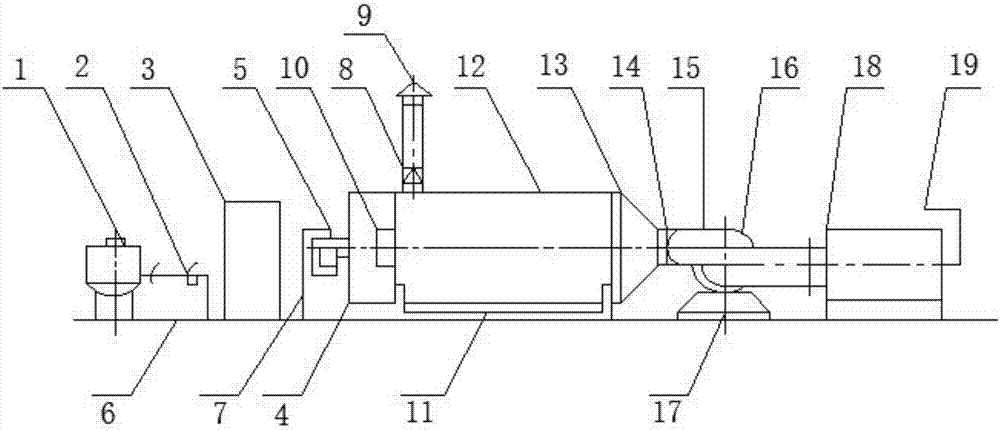

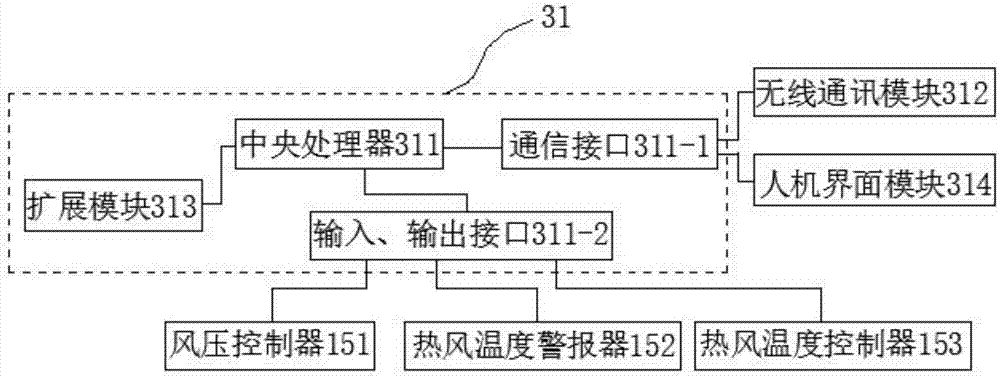

[0017] see Figure 1-2 , the present invention provides a technical solution: a fuel-fired hot air stove with an intelligent control terminal, including an oil storage tank 1, a main valve oil filter 2, a control box 3, a burner 4, an oil pipe 6, an oil inlet pipe 7, a chimney 9, Hot air outlet 10, heat exchanger 12, air inlet cover 13, air blower 16, air filter 18 and cold air inlet 19; the oil pipe 6 is laid on the access opening of the fuel hot blast stove; the oil storage tank 1 and the main valve filter oil The oil filter 2 is connected through the oil pipe 6, and the control box 3 is arranged on the right side of the main valve oil filter 2; the left port of the heat exchanger 12 is connected to the burner 4, and the right port is connected to the air inlet cover 13, and the bottom of the heat exchanger 12 is provided with a Seat 11, a burner seat 5 is provided at the bottom of the burner 4, and a hot air outlet 10 is provided at the connection with the burner 4; the bur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com