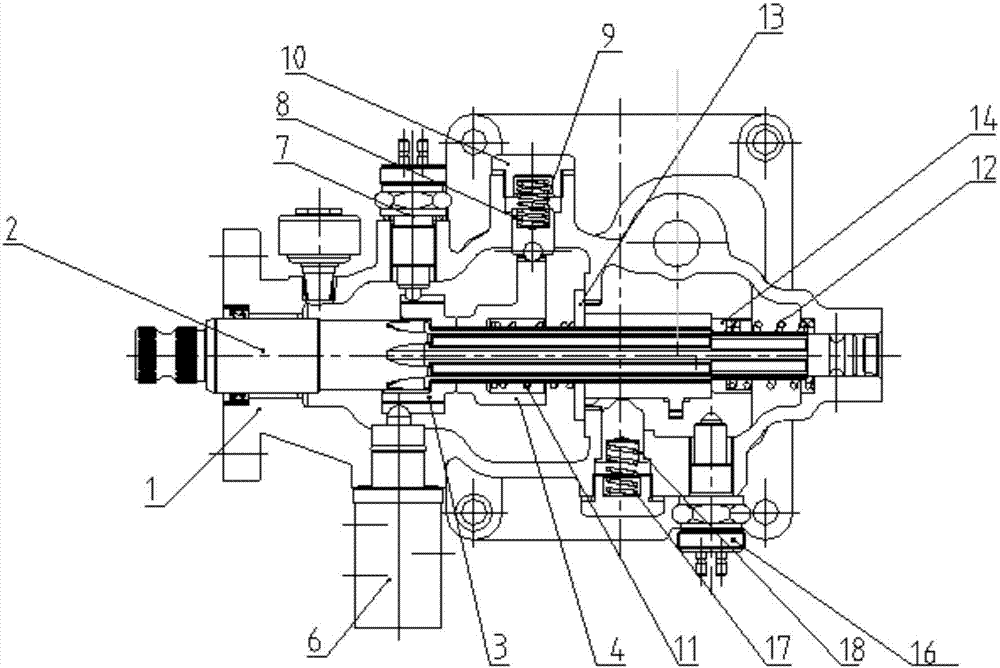

Transmission double-lever control device assembly

A technology for operating devices and transmissions, applied in transmission control, components with teeth, belts/chains/gears, etc. Consistency, Cost Reduction, Part Count Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

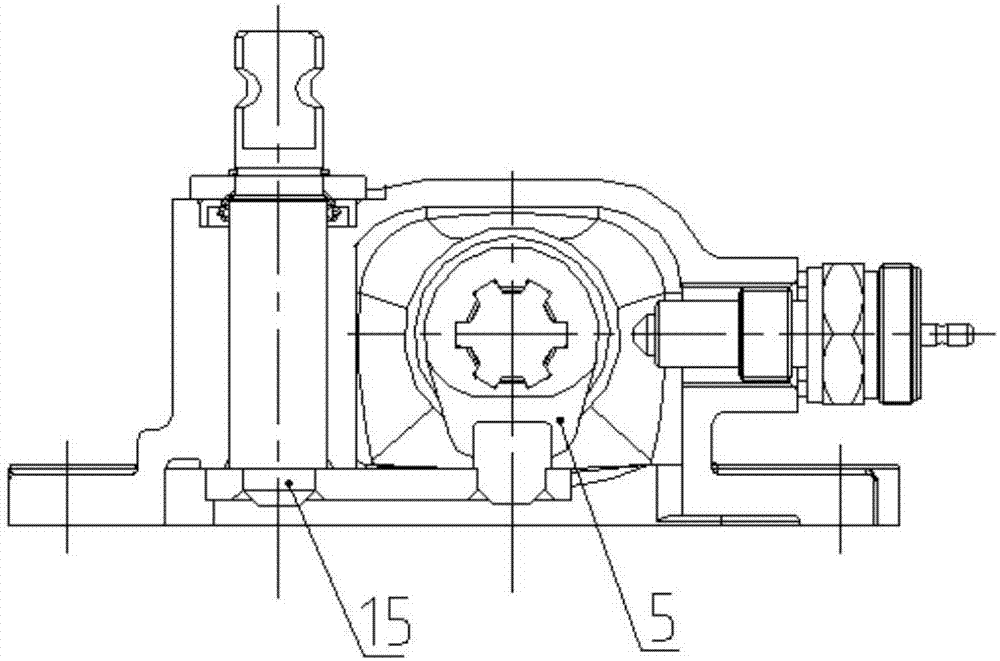

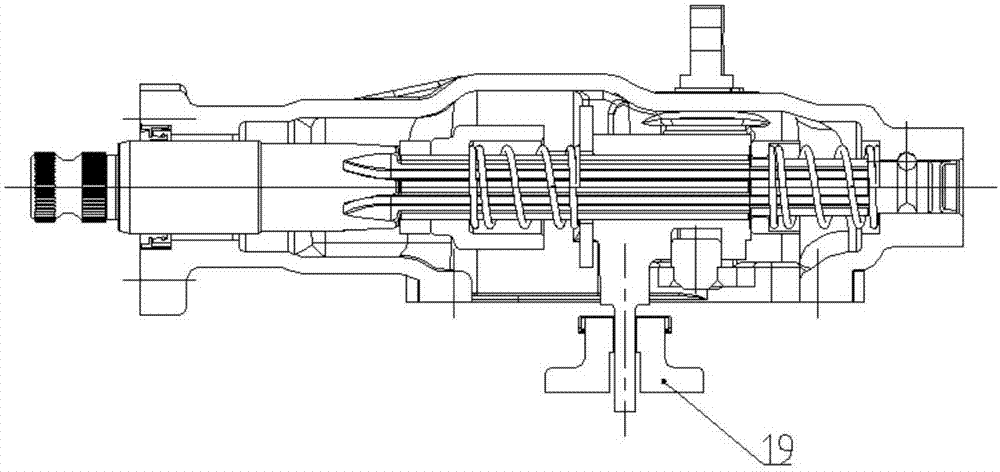

[0045] The working principle of a transmission double-lever operating device assembly provided by the present invention in forward gear will be described in detail below.

[0046] First, the gear selection operation is performed, and the gear selection shaft assembly 15 drives the shift dial 5 to move axially to the forward gear selection position; at this time, the shift dial 5 is in the neutral position, and the self-locking pin 8 is in the self-locking position. In the groove of the first boss on the control block 4, the neutral gear is positioned; the ejector rod of the air circuit control valve 6 and the ejector rod of the neutral gear indicator switch 7 are located in the corresponding V-shaped groove on the switch control block 3, and the air Road control valve 6 and neutral indicator switch 7 are both in open state; the handle pin 18 of the reverse gear lock assembly is in contact with the circumferential surface of the shift knob 5, and the reverse gear indicator switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com