Lock cylinder structure

A technology of lock cylinder and lock cylinder hole, which is applied in the direction of building locks, building structures, construction, etc., can solve the problems of increased production and management costs, increased customer choice troubles, and low versatility of locks, so as to reduce production and The effect of cost management and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

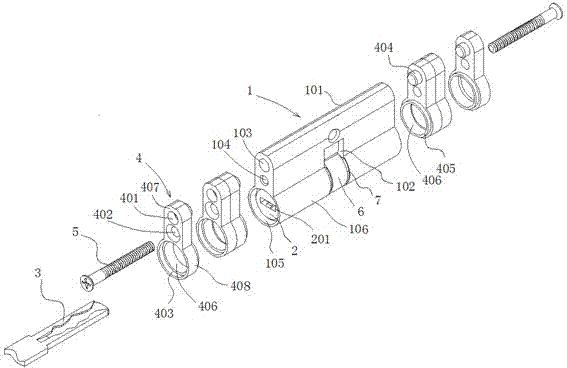

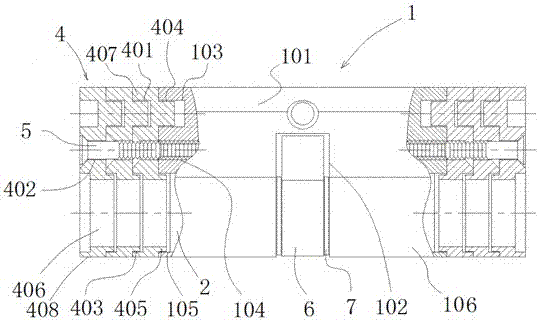

[0014] See figure 1 , figure 2 , the lock core structure provided by the present invention includes a body 1, the body 1 includes a lock tube 106 and a lock block 101 located above the lock tube 106, the lock core hole 105 of the lock tube 106 is equipped with a key hole 201, a lock core 2, and a lock block 101 is equipped with a pin assembly that matches with the lock cylinder 2, and the lock cylinder 2 is fixed in the lock cylinder hole 105 through the snap spring 7. The middle part of the lock tube 106 is provided with a toggle groove 102, and the toggle groove 102 is provided with a lock cylinder 2. The matching dial 6 is respectively provided with a plurality of lock sleeves 4 that can be combined with the shape of the body 1 and are provided with through holes 406 at both ends of the body 1. The lock sleeves 4 include The sleeve body 408 and the sleeve block 407 corresponding to the lock tube 106 and the lock block 101, the through hole 406 is arranged on the sleeve bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com