Metal substrate circuit board welding tool and application method thereof

A metal substrate and welding tooling technology, which is applied in metal processing equipment, welding equipment, and the assembly of printed circuits with electrical components, can solve the problems of poor welding reliability, increased void probability, and easy generation of air bubbles. Improve welding quality and ensure the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

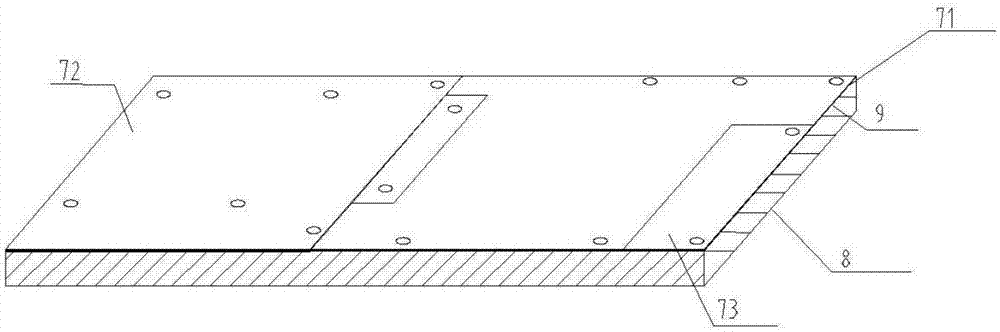

[0035] Such as Picture 10 Shown is a metal substrate circuit board welding tool, the metal substrate circuit board to be processed by this tool is such as figure 1 As shown, this type of circuit board product requires soldering three printed circuit boards 71, 72, and 73 on a metal substrate 8. The metal substrate 8 is provided with threaded holes for fixing the circuit board. A field effect tube should be installed between the circuit boards 71 and 72, and a fixed screw hole is provided on the metal substrate for fixing the field effect tube. The metal base plate 8 plays a dual role. It is not only a base plate that is used as a product material for welding with the circuit board 7, but also a tooling base plate for fixed installation of the entire assembly of backing plates and pressing plates.

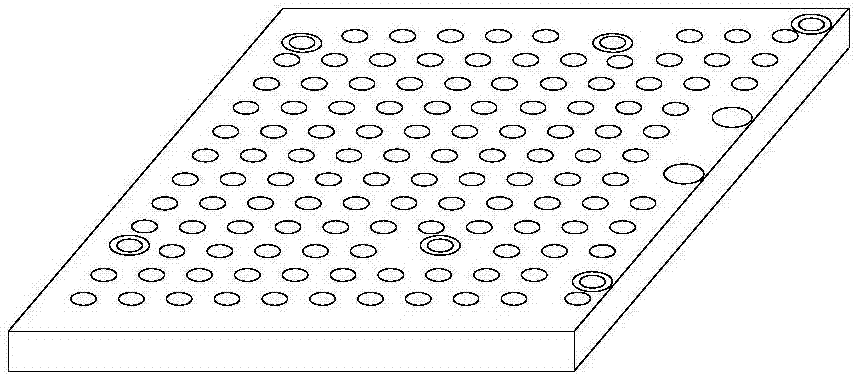

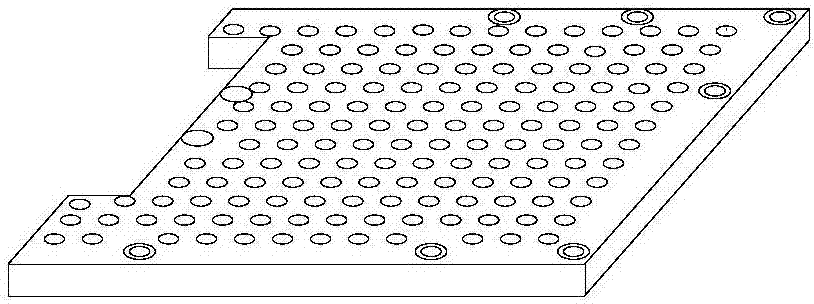

[0036] The welding tool includes a backing plate, and the backing plate is evenly distributed with vent holes. Such as figure 2 , 3 As shown, the backing board is divided into two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com