Single-main-cylinder pull-down type large ring piece bulging machine

A bulging machine, large-scale technology, applied in metal processing equipment, manufacturing tools, safety equipment, etc., can solve problems such as difficult operation, troublesome maintenance, heavy equipment weight, etc., to achieve easy maintenance, small equipment weight, and good stress state Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

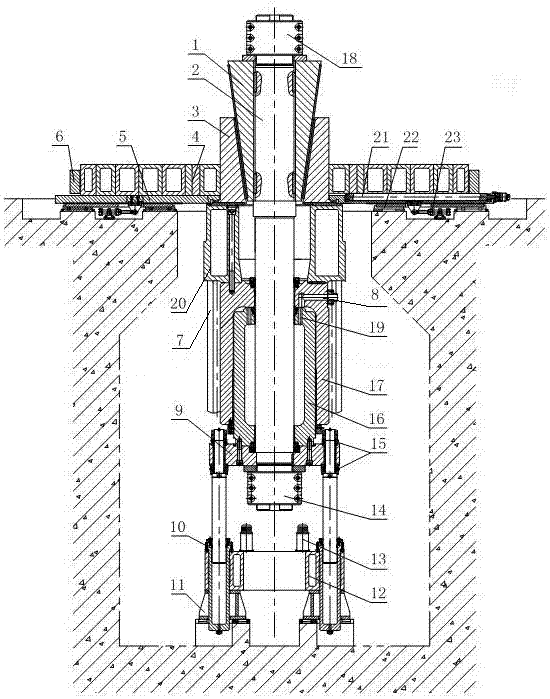

[0033] This embodiment provides a Figure 1 to Figure 4 The single master cylinder pull-down large-scale ring bulging machine shown includes a workbench 5 above the foundation and a base 11 inside the foundation. An inner groove is arranged below the foundation level, and the inner groove communicates with the upper part of the foundation level. The workbench 5 The upper parts are all above the foundation level, and the rest are placed in the inner groove of the foundation. It also includes a center tie rod 2 and a bulging mold 4. The center tie rod 2 passes through the center of the workbench 5, and the outside of the center tie rod 2 is drawn from the top. The bulging core cone 1, the upper beam 20, the main cylinder body 17, and the moving beam 9 are set sequentially from the bottom, and the bulging mold 4 is placed on the workbench 5, and the bulging mold 4 is located outside the bulging core cone 1. The outer diameter of the bulging core cone 1 decreases successively from...

Embodiment 2

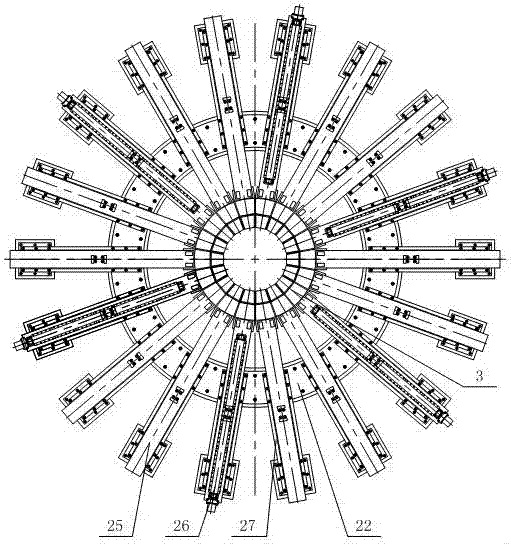

[0038] On the basis of Embodiment 1, this embodiment provides a single master cylinder pull-down large-scale ring bulging machine. The workbench 5 includes an annular fixing seat 22 on which a plurality of Groove 27, slide rail 21 is all provided on a plurality of slide grooves 27, and described bulging mold 4 is placed on slide rail 21, reset oil cylinder 23 is all equipped with below each slide rail 21, described bulging core cone 1 outside There are a plurality of bulging inclined blocks 3 distributed in the circumferential direction, and a plurality of bulging inclined blocks 3 are placed on the upper beam 20, and a plurality of sets of slide rails 21 are radially distributed uniformly, and the inner end of each slide rail 21 is connected with a bulging inclined block. Block 3 is connected.

[0039] The outer diameter of the bulging core cone 1 decreases sequentially from top to bottom, through the contact between the bulging core cone 1 and the bulging slanting block 3, t...

Embodiment 3

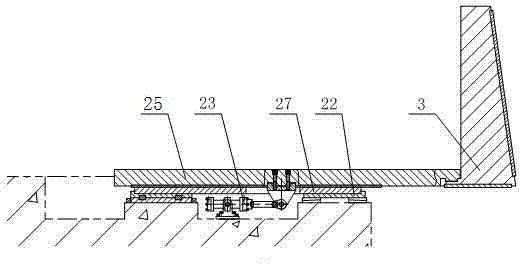

[0042] On the basis of Embodiment 2, this embodiment provides a single master cylinder pull-down large-scale ring bulging machine. The slide rail 21 includes a roller slide rail 26 and a roller slide rail 25, and the roller slide rail 26 and the roller-less slide rail 25 are evenly spaced along the circumferential direction.

[0043] Further, the slide rail of the roller slide rail 26 is provided with a groove, and the rotating roller 24 is housed in the groove, and the highest position of the rotating roller 31 is higher than the upper surface of the slide rail of the roller slide rail 26, and the roller slide The outer end surface of the rail 26 is also equipped with a hydraulic motor 28 , and the hydraulic motor 28 is connected with the rotating roller 24 .

[0044] When the bulging mold 4 moves radially inward synchronously and resets, the outermost bulging mold 4 is disengaged from the inner wall of the ring 6 , and the hydraulic motor 28 drives the rotating roller 24 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com