Iron-doped modified carbon nitride photocatalyst, and preparation method and application thereof

An iron doping and catalyst technology, applied in the field of photocatalysis, can solve the problems of low photocatalytic activity of barbituric acid modified carbonized nitrogen, high requirements for organic solvent equipment, and complicated modification methods, so as to promote carrier transport , improve photocatalytic activity, and facilitate large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of iron-doped modified carbon nitride photocatalyst, its preparation method is as follows:

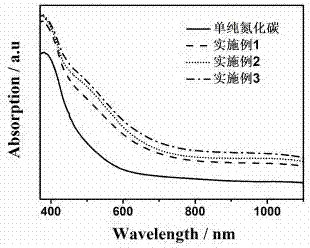

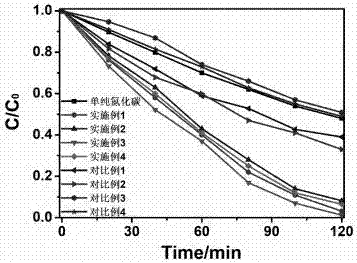

[0029] Take by weighing 10g dicyandiamide, 0.2g barbituric acid, 5g Fe (NO 3 ) 3 (The mass ratio of the three is 100:2:50) Dissolve in 50ml of deionized water, heat and stir at 60°C to speed up the dissolution, and make it evenly dispersed in water; put the above mixed solution in a blast drying oven, and dry at 100°C Dry for 5 hours to obtain a white mixture powder; calcinate the mixed powder in a muffle furnace at a heating rate of 5°C / min, raise it to 550°C and keep it for 2 hours to obtain the above-mentioned iron-doped modified carbon nitride composite light catalyst. And apply it to photocatalytic degradation of phenol solution degradation results see attached figure 2 .

Embodiment 2

[0031] A kind of iron-doped modified carbon nitride photocatalyst, its preparation method is as follows:

[0032] Weigh 10g dicyandiamide, 0.15g barbituric acid, 1g FeCl 3 (The mass ratio of the three is 100:1.5:10) Dissolve in 50ml of deionized water, heat and stir at 60°C to speed up the dissolution, and make it evenly dispersed in water; put the above mixed solution in a blast drying oven, and dry at 100°C Dry for 5 hours to obtain a white mixture powder; calcinate the mixed powder in a muffle furnace at a heating rate of 5°C / min, raise the temperature to 550°C and keep it for 2 hours to obtain the above-mentioned iron-doped carbon nitride composite photocatalyst. And apply it to photocatalytic degradation of phenol solution degradation results see attached figure 2 .

Embodiment 3

[0034] A kind of iron-doped modified carbon nitride photocatalyst, its preparation method is as follows:

[0035] Weigh 5g dicyandiamide, 0.1g barbituric acid, 0.5g Fe (NO 3 ) 3 (The mass ratio of the three is 5:0.1:0.5) Dissolve in 50ml of deionized water, heat and stir at 60°C to speed up the dissolution, and make it evenly dispersed in water; put the above mixed solution in a blast drying oven, and dry at 100°C Dry for 5 hours to obtain a white mixture powder; calcinate the mixed powder in a tube furnace at a heating rate of 5°C / min, raise it to 550°C and keep it for 3 hours to obtain the above-mentioned iron-doped modified carbon nitride composite light catalyst. And apply it to photocatalytic degradation of phenol solution degradation results see attached figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com