A kind of low-quality heavy oil suspended bed hydrocracking catalyst and preparation method

A technology for hydrocracking and low-quality heavy oil, applied in the field of petrochemical industry, can solve the problems of high production cost, unsatisfactory desulfurization effect, cumbersome preparation process, etc., achieve strong coke loading capacity, improve hydrocracking desulfurization reaction activity, and desulfurization effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

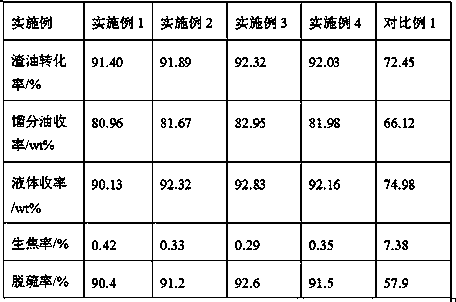

Examples

Embodiment 1

[0032] Mix 35.00g of kaolin powder and 33.00g of iron-containing ore (both 90 mesh) evenly, then use a vulcanizing agent for vulcanization. The vulcanizing agent is carbon disulfide, and then dry-mix with 32.00g of 90-mesh zinc oxide powder, stir well, and mix Catalyst 1 was obtained after homogenization.

Embodiment 2

[0034] Under stirring conditions, 0.25mol La (NO 3 ) 3 Dissolve in 100 mL of water, add citric acid and stir to dissolve; then add 0.5 mol Fe(NO) 3 ) 3 , and then add 18 g of sodium polyacrylate, continue to stir for 30 minutes to obtain a reaction solution, which is calcined and ground to obtain micro-mesoporous lanthanum ferrite.

[0035] After roasting kaolin powder and iron-containing ore powder at 430℃, mix 40.00g kaolin powder and 30.00g iron-containing ore (both 60 mesh) evenly, and then use vulcanizing agent for vulcanization treatment. The vulcanizing agent is sulfur powder, 5g After vulcanization, the micro-mesoporous lanthanum ferrite powder was dry-mixed with 30.00 g of zinc oxide powder containing zinc-aluminum spinel structure, and then mixed with kaolin powder and iron-containing ore powder, fully stirred, and mixed uniformly to obtain catalyst 2.

Embodiment 3

[0037] After roasting kaolin powder and iron-containing ore powder at 450℃, mix 20.00g kaolin powder and 55.00g iron-containing ore (both 80 mesh) evenly, and then use vulcanizing agent for vulcanization treatment. The vulcanizing agent is carbon disulfide, 25.00g Zinc oxide powder containing zinc-aluminum spinel structure was mixed with 5g of waste ZSM-5, and then dry-mixed with 7g of vulcanized micro-mesoporous lanthanum ferrite powder, mixed uniformly, and then mixed with kaolin powder and iron-containing ore mixture uniformly , to obtain catalyst 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com