High-voltage line deicing device convenient for identification

An easy-to-identify technology for high-voltage wires, applied in the installation of cables, electrical components, overhead installations, etc., can solve problems such as broken high-voltage wires, impact on production and life, and paralysis of photographed areas, so as to prolong service life and save manpower input , the effect of reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

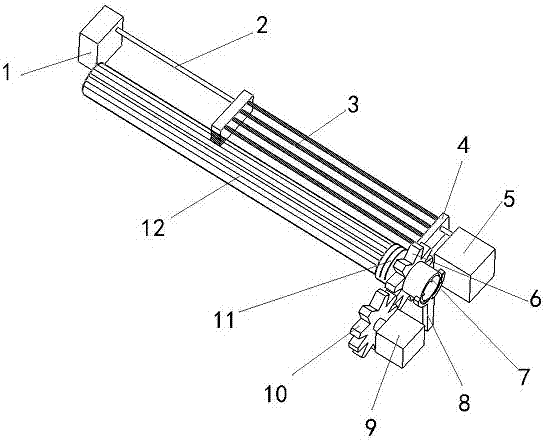

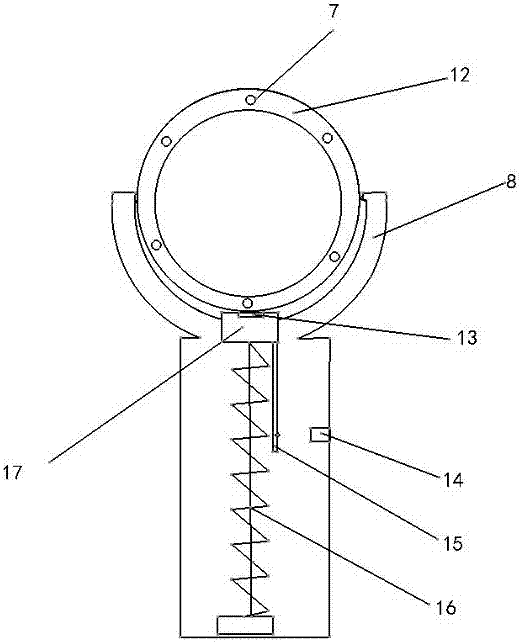

[0021] Such as figure 1As shown, an easily identifiable high-voltage wire deicing device includes a rotating device, a cutting device and a trigger device; the rotating device includes a sleeve 12, a driving gear 10, a driven gear 6, a sliding sleeve 11 and a motor three 9; The sleeve 12 is provided with a heating wire 7; the sleeve 12 wraps the high-voltage wires and has intervals between them; the sleeve 12 is arranged on the support rod 8; the sleeve 12 and The grooves of the support rod 8 are partially in contact; the inner interlayer of the sleeve 12 is provided with a plurality of heating wires 7; the heating wires 7 are arranged in the interlayer of the sleeve 12 in an encircling manner and are spaced from each other; Described drive gear 10 is located on motor three 9; Described drive gear 10 is positioned at the side of sleeve 12; Described driven gear 6 is fixed on the sliding sleeve 11; Described driven gear 6 and support bar There is a space between 8; there is a ...

Embodiment 2

[0024] Such as figure 1 As shown, an easily identifiable high-voltage wire deicing device includes a rotating device, a cutting device and a trigger device; the rotating device includes a sleeve 12, a driving gear 10, a driven gear 6, a sliding sleeve 11 and a motor three 9; The sleeve 12 is provided with a heating wire 7; the sleeve 12 wraps the high-voltage wires and has intervals between them; the sleeve 12 is arranged on the support rod 8; the sleeve 12 and The grooves of the support rod 8 are partially in contact; the inner interlayer of the sleeve 12 is provided with a plurality of heating wires 7; the heating wires 7 are arranged in the interlayer of the sleeve 12 in an encircling manner and are spaced from each other; Described drive gear 10 is located on motor three 9; Described drive gear 10 is positioned at the side of sleeve 12; Described driven gear 6 is fixed on the sliding sleeve 11; Described driven gear 6 and support bar There is a space between 8; there is a...

Embodiment 3

[0027] The third embodiment is basically the same in structure and principle as the first embodiment, except that the resistance wire 3 is replaced by other heatable metal wires, which can still achieve the purpose of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com