A kind of material automatic sampling system and sampling method

An automatic sampling and material technology, applied in the direction of sampling devices, etc., can solve the problems of not being able to truly reflect the quality of materials, affecting the accuracy of detection, and intermixing of products, so as to reduce skill level requirements, simplify operations, and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

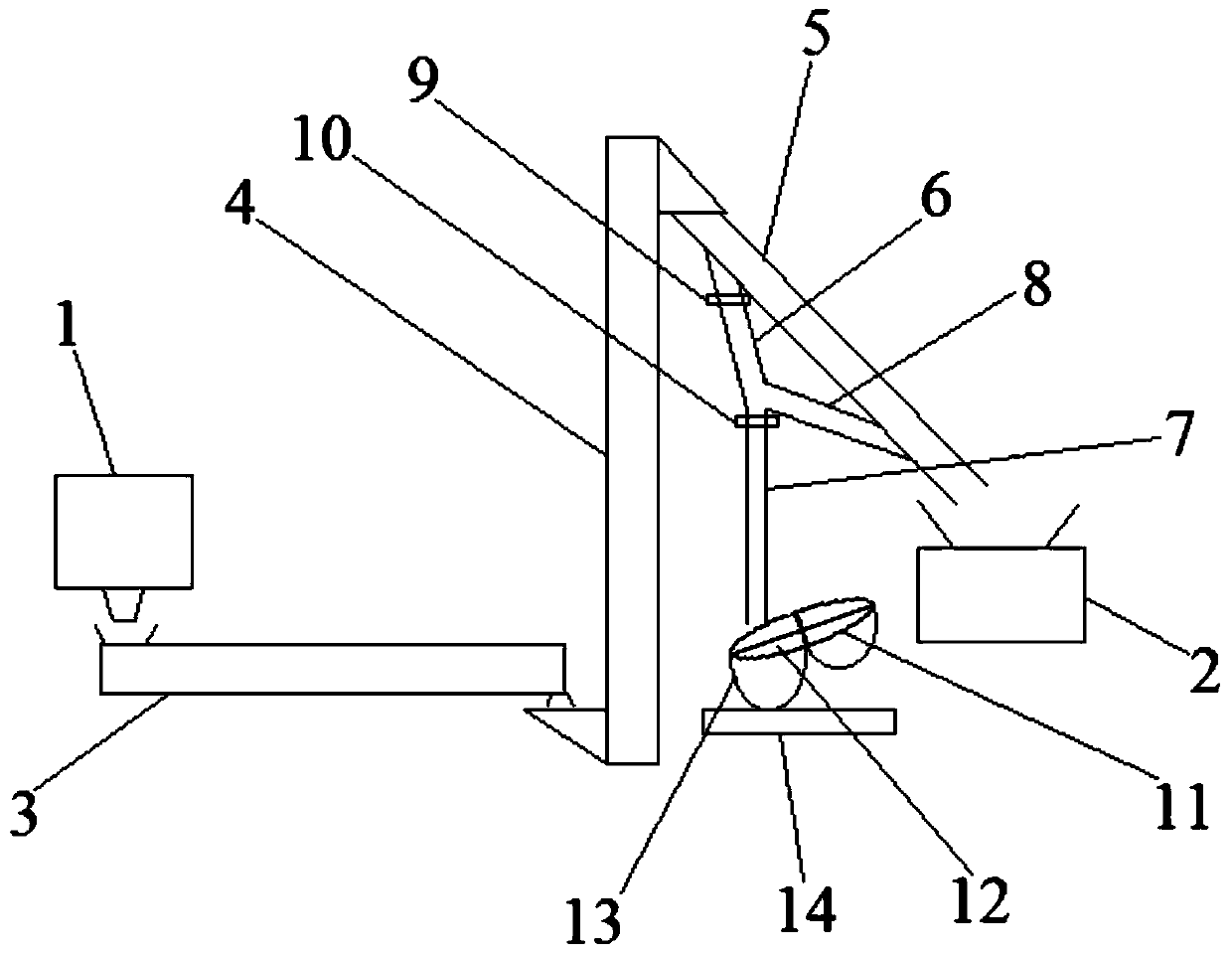

[0026] Such as figure 1 A material automatic sampling system is shown, the system is arranged between the mixer 1 and the silo 2, and it is characterized in that the system includes a conveyor 3 arranged below the mixer 1, an elevator arranged at one end of the conveyor 3 4. The material guide chute 5 and the controller are arranged obliquely between the top of the hoist 4 and the silo 2. A three-way material guide mechanism connected with the material guide 5 is provided below the material guide 5. The bottom of the three-way material guide mechanism is provided with a sample distribution and collection mechanism, and the controller is electrically connected to the three-way material guide mechanism and the sample distribution and collection mechanism respectively.

[0027] Wherein, the three-way material guide mechanism includes a feed pipe 6 arranged below the feed pipe 5 and communicated with the feed pipe 5, a sampling pipe 7 arranged at the bottom of the feed pipe 6 and ...

Embodiment 2

[0033] In this embodiment, three sampling ports 12 are evenly opened on the distribution plate 11, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com