A jig for anode baking and method thereof

A fixture and roasting technology, which is applied in furnaces, charge control, lighting and heating equipment, etc., can solve the problems of insufficient clamping and locking force, difficult to grasp carbon blocks, etc., and achieve the effect of easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

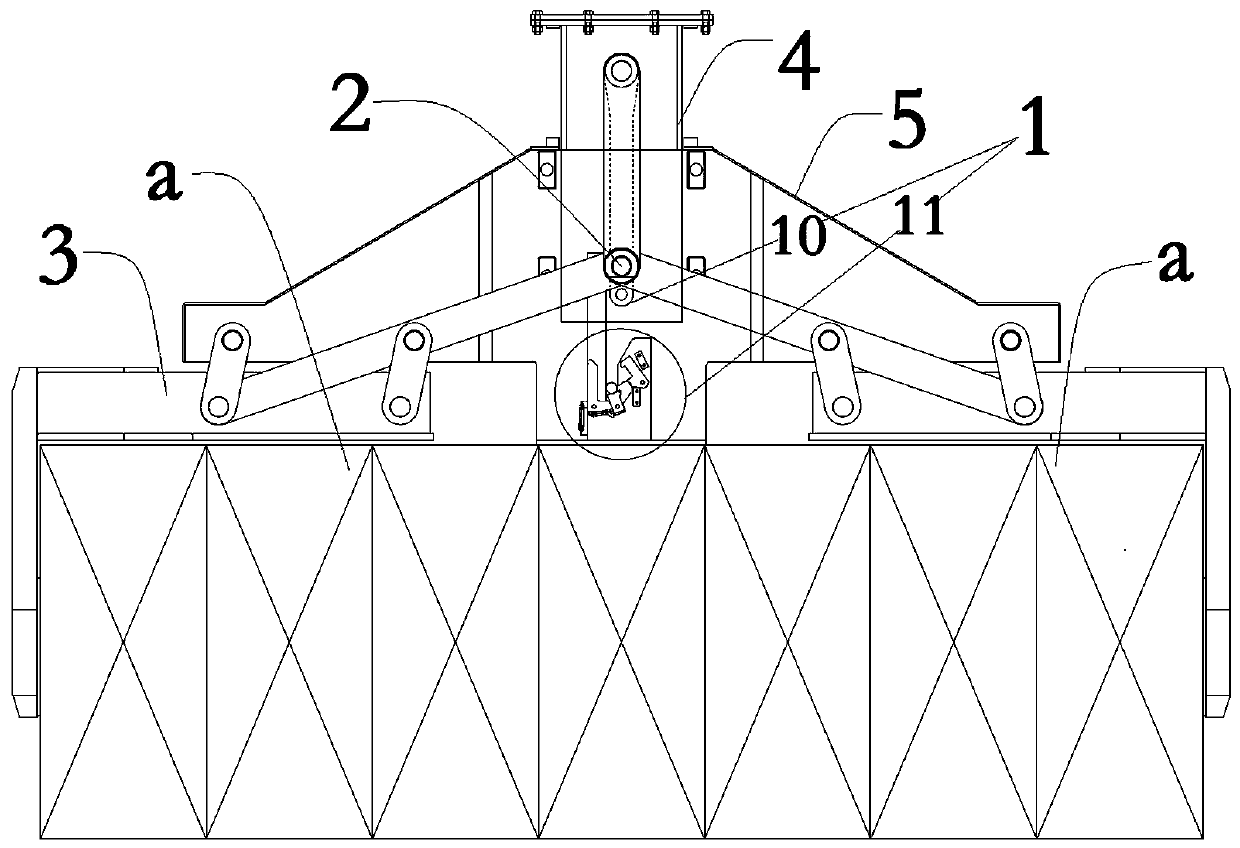

[0048] Such as Figure 1-10 As shown, in this embodiment, a fixture for anode baking is provided, which is used to clamp the carbon block a, including the fixture shell 5, the guide sleeve 4 arranged on the upper part of the fixture shell, the splint 3 and the The internal driving device 2 is connected to the locking device 1, and the driving device 2 is connected to the splint 3;

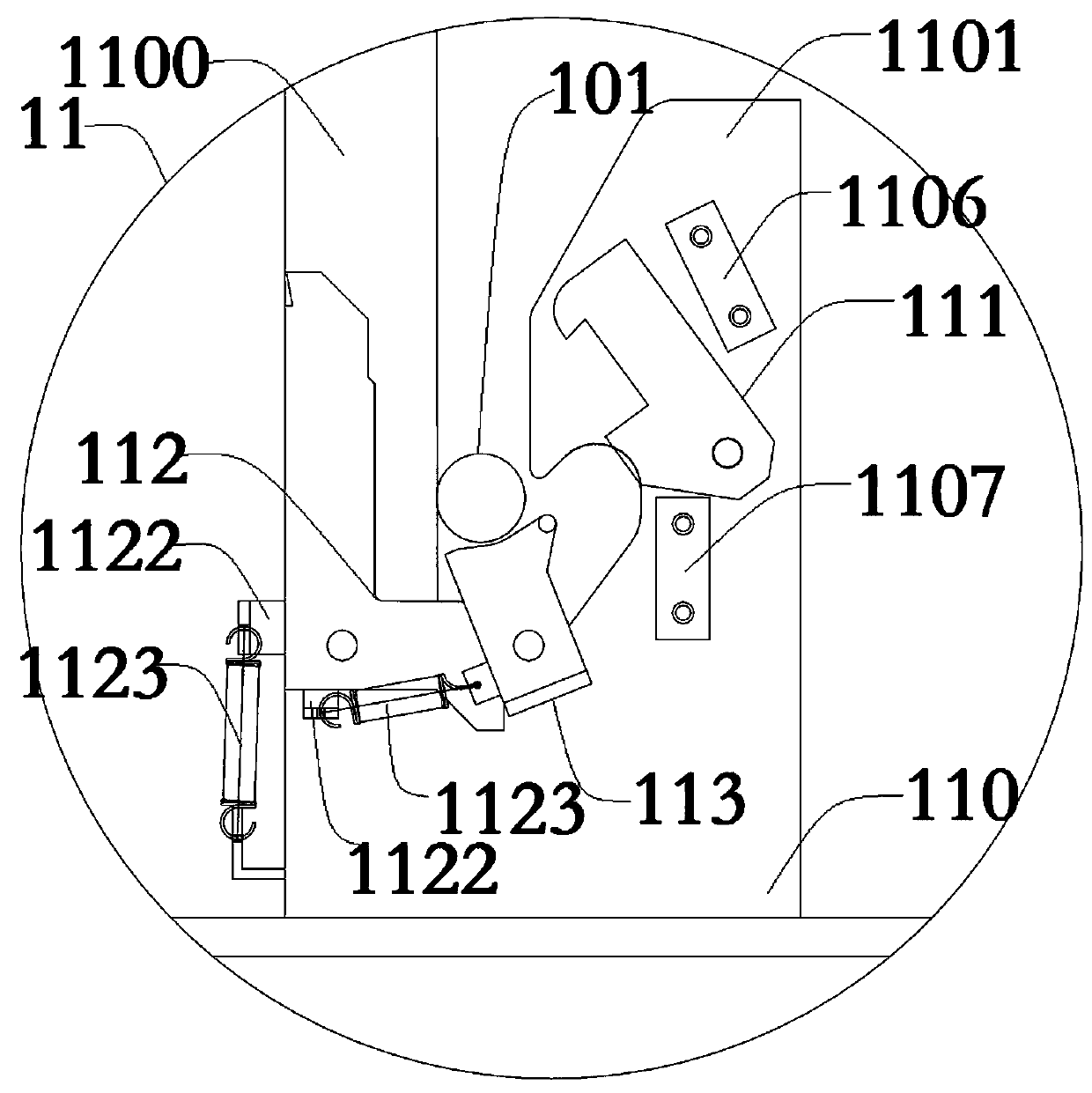

[0049] Such as figure 2 As shown, the locking mechanism 1 includes a locking trigger mechanism 10 and a locking mechanism 11;

[0050] The locking trigger mechanism 10 includes a guide rod 100 fixed at one end inside the guide sleeve 4 and a hinge shaft 101 at the other end of the guide rod 100;

[0051] The locking mechanism 11 includes a lifting plate 110, a groove body 111 arranged on the lifting plate 110, a connecting rod 112 and a swinging rod 113;

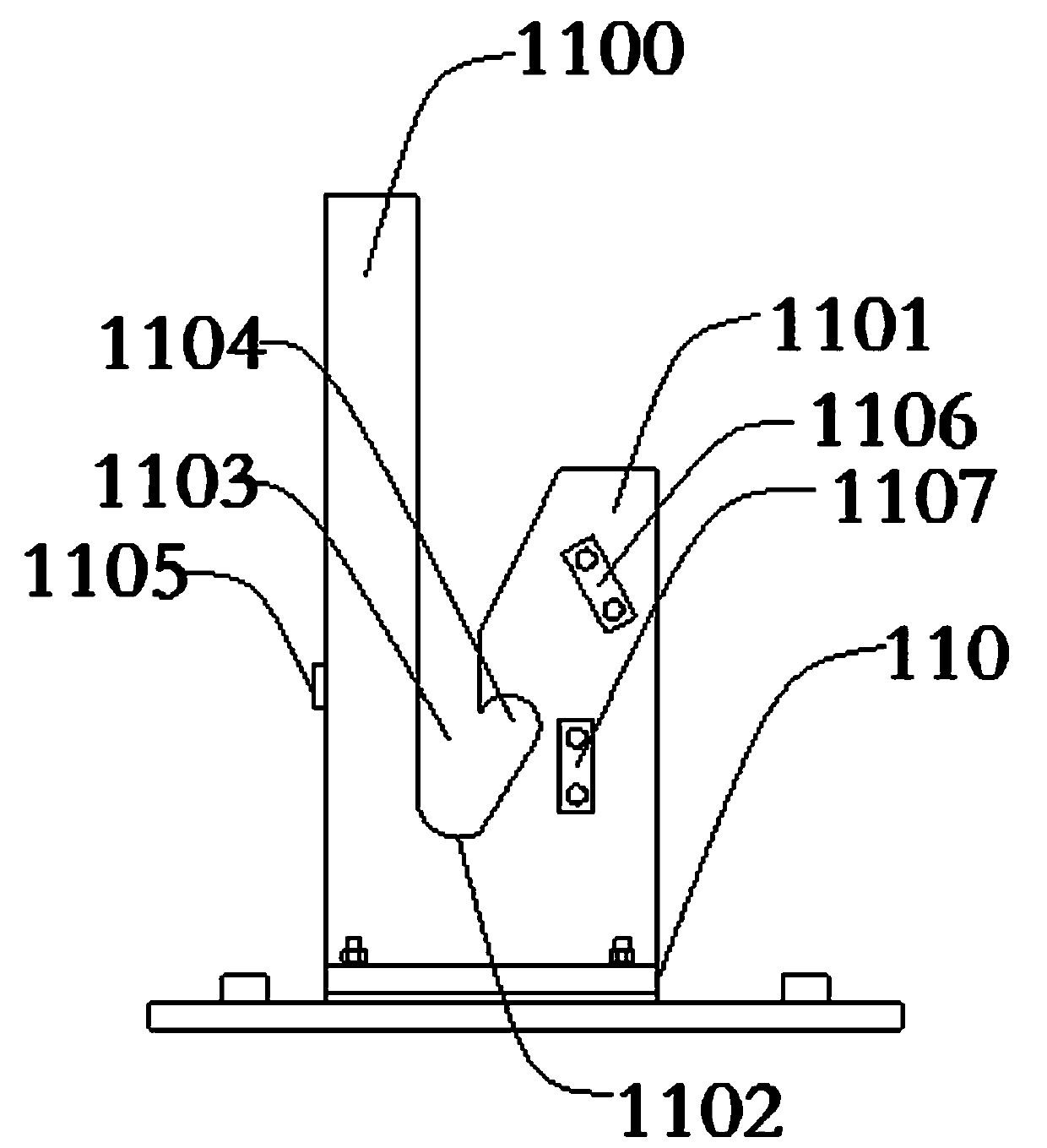

[0052] Such as image 3 As shown, the lifting plate 110 includes a guide part 1100 and a lock hook part 1101, a "し" shaped cavity 1102 is f...

Embodiment 2

[0073] Such as Figure 10 As shown, the only difference from Embodiment 1 is that there is only one connecting plate 24 , one end is movably connected with the ends of the transmission shafts 21 and 22 , and the other end is movably connected with the clamp housing 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com