A fuel injector with filter inner core

A fuel injector and inner core technology, which is applied in fuel injection devices, machines/engines, charging systems, etc., to reduce production efficiency, prevent wear of injector parts, and ensure cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

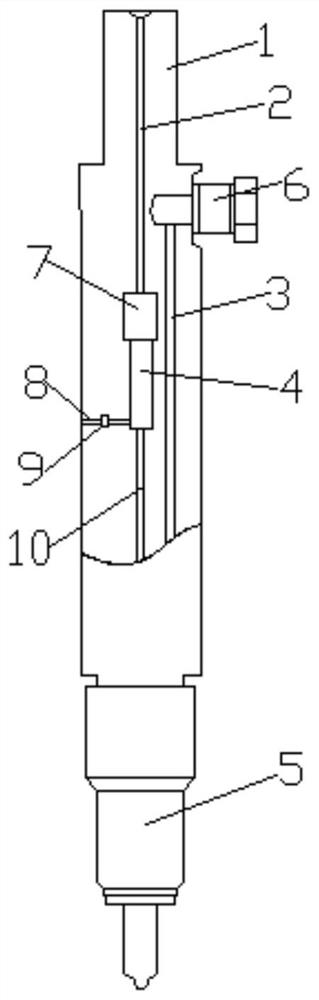

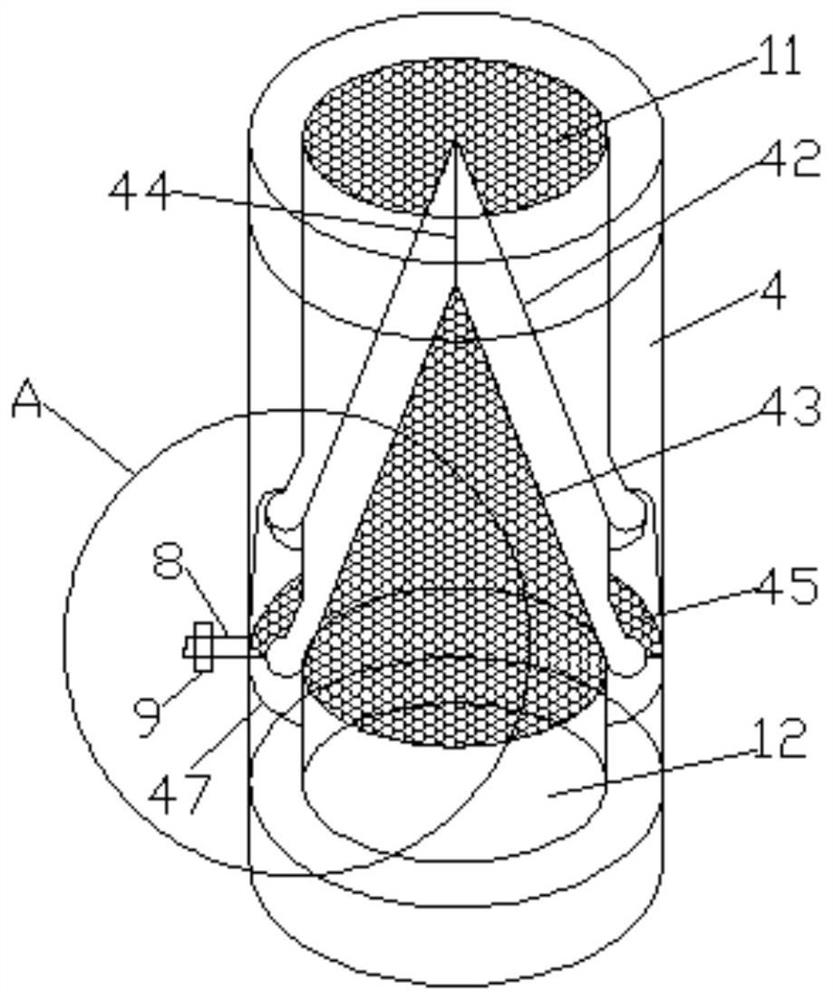

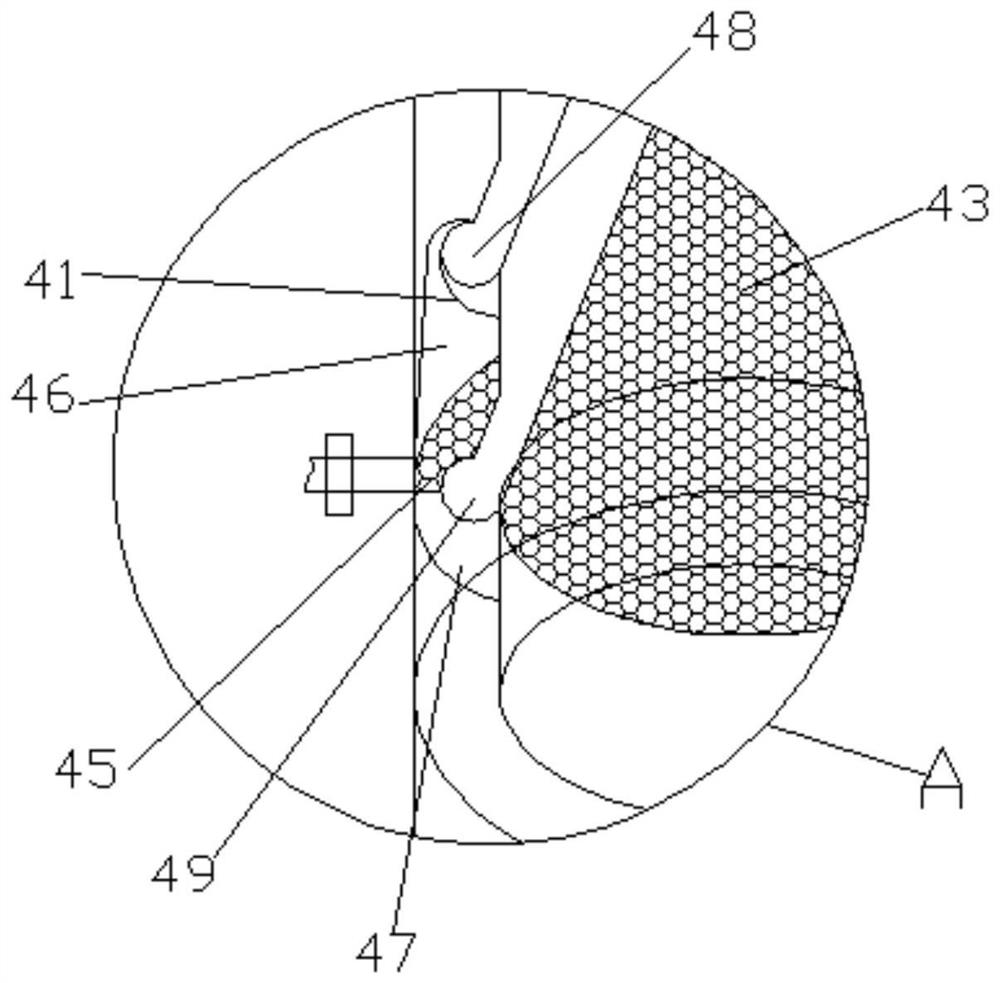

[0020] Such as Figure 1-3 A fuel injector with a filter core is shown, which includes a fuel injector body 1 and a fuel injector assembly 5 connected to the head of the fuel injector body. The fuel injector body 1 is provided with a first The oil inlet passage 2 and the first oil outlet passage 3, the first oil inlet passage 2 communicates with an oil storage chamber 7, the first oil outlet passage 3 communicates with an oil return pipe 6, and the lower end of the oil storage chamber 7 communicates with a A filter mechanism 4, the filter mechanism 4 includes a filter cavity and a primary filter screen 11 that communicates with the lower end of the oil storage cavity 7 and is fixed on the upper end surface of the filter cavity. There are both conical secondary filter screens 42 and tertiary filter screens 43, the lower end of the tertiary filter screen 43 communicates with the second oil outlet passage 12, and the second oil outlet passage 12 communicates with the second oil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com