A kind of surface waterproof protective agent and its preparation and application method

A technology of protective agent and coupling agent, used in fire-resistant coatings, coatings, etc., can solve the problems of structural durability failure of characteristic materials, failure to reach the designed service life, etc., and achieve the effect of simple use method and improved durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method for a surface waterproof protector, comprising the following steps:

[0027] 1) Mix coupling agent, metasilicic acid and water in a reaction kettle;

[0028] 2) heating the mixed solution obtained in step 1) to 25-35°C and stirring;

[0029] 3) Continue heating to 45-55°C and stir;

[0030] 4) Maintain the temperature in step 3), add triisopropylsilane, butyl orthosilicate, n-octyltriethoxysilane and isooctyltriethoxysilane, mix and stir;

[0031] 5) Heating the mixed liquid obtained in step 4) to 75-85° C., stirring, cooling and discharging to obtain a waterproof and protective agent for the surface of porous foam concrete. The composition of the surface waterproof and protective agent for porous foam concrete is as above.

[0032] Preferably, in step 2), the stirring time is 8-15 min; further preferably, in step 2), the stirring time is 10 min.

[0033] Preferably, in step 3), the stirring time is 12-20 min; more preferably, in step 3), the sti...

Embodiment 1

[0039] Its raw material composition of the surface waterproof protective agent of embodiment 1 is as shown in table 1.

[0040] The surface waterproof protective agent of table 1 embodiment 1

[0041] raw material parts by mass Triisopropylsilane 12 Orthobutyl silicate 5 n-Octyltriethoxysilane 15 Isooctyltriethoxysilane 10 metasilicate 7 coupling agent 12 water 39

[0042] The preparation method of the surface waterproof protective agent of embodiment 1 is:

[0043] 1) Add deionized water, water-based silane coupling agent and metasilicate in the cleaned reaction kettle in sequence according to the above ratio;

[0044] 2) Heat the reactor to 25°C, then start timing and stir for 10 minutes;

[0045] 3) Heating to 55°C, stirring for 15 minutes, and maintaining the temperature;

[0046] 4) Add triisopropylsilane, butyl orthosilicate, n-octyltriethoxysilane and isooctyltriethoxysilane in proportion to the reaction kettle...

Embodiment 2

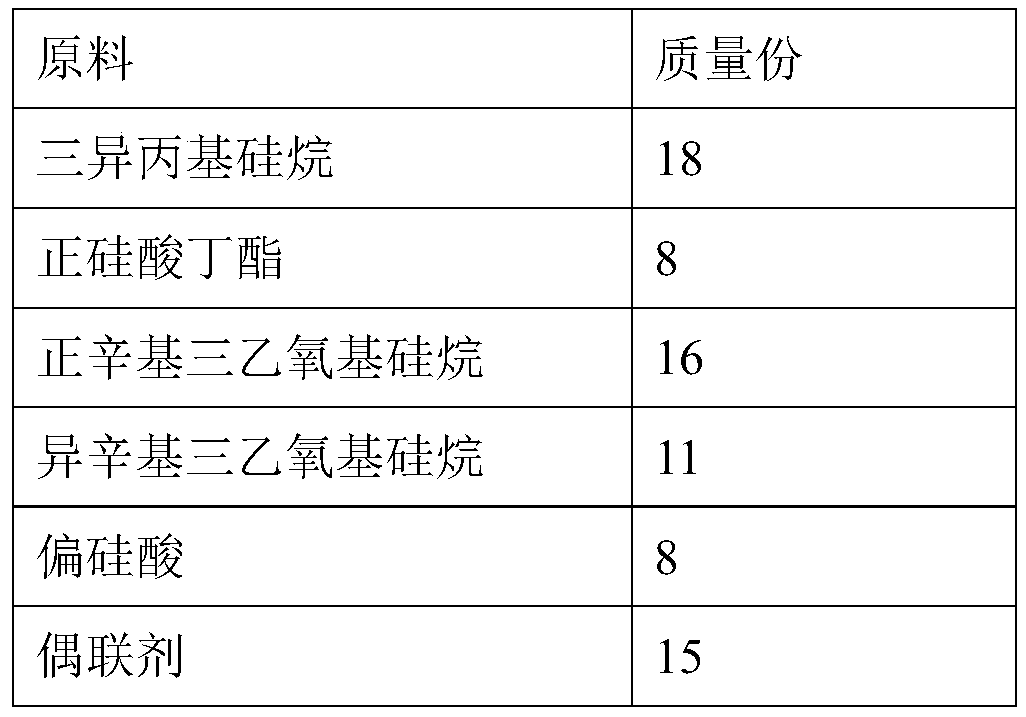

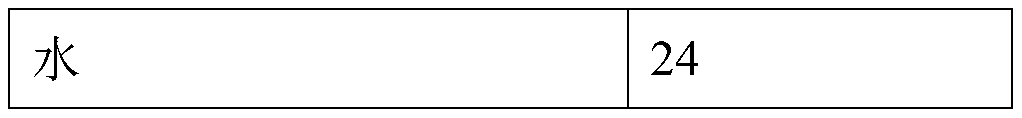

[0049] Its raw material composition of the surface waterproof protective agent of embodiment 2 is as shown in table 2.

[0050] The surface waterproof protective agent of table 2 embodiment 2

[0051] raw material parts by mass Triisopropylsilane 15 Orthobutyl silicate 3 n-Octyltriethoxysilane 18 Isooctyltriethoxysilane 12 metasilicate 4 coupling agent 10 water 38

[0052] The preparation method of the surface waterproof protective agent of embodiment 2 is:

[0053] 1) Add deionized water, water-based silane coupling agent and metasilicate in the cleaned reaction kettle in sequence according to the above ratio;

[0054] 2) Heat the reactor to 25°C, then start timing and stir for 10 minutes;

[0055] 3) Heating to 50°C, stirring for 15 minutes, and maintaining the temperature;

[0056] 4) Add triisopropylsilane, butyl orthosilicate, n-octyltriethoxysilane and isooctyltriethoxysilane in proportion to the reaction kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com