Sticking and plugging prevention hybrid breaker

A hybrid and crusher technology, applied in the field of mechanical equipment, can solve problems such as stuck, large particle size, blockage, etc., and achieve the effects of improved efficiency, simple structure, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

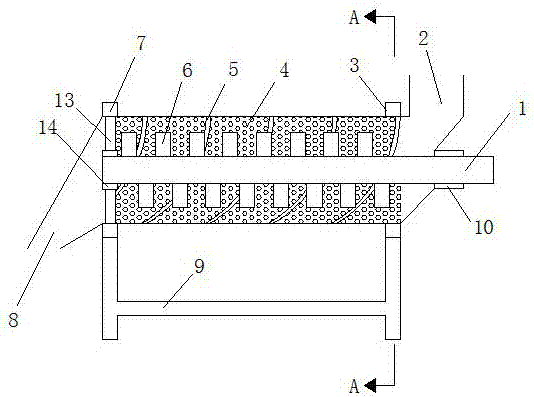

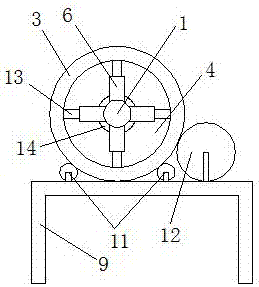

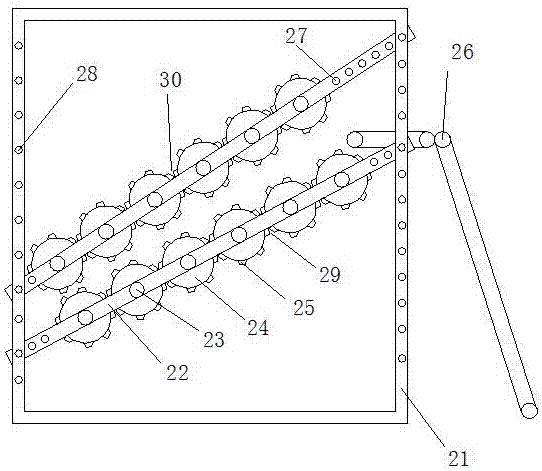

[0037] As a preferred embodiment of the present invention, with reference to the attached figure 1 , attached figure 2 And attached image 3 , this embodiment discloses an anti-blocking hybrid crusher, this embodiment includes:

[0038] An anti-blocking hybrid crusher, comprising a first crushing mechanism and a second crushing mechanism, the first crushing mechanism includes a bracket 21, and the bracket 21 is provided with a crushing roller group 1 29 and a crushing roller group 2 30, the crushing rollers Group 1 29 and crushing roller group 2 30 are arranged side by side by multiple crushing rollers 24, crushing roller group 2 30 is arranged above crushing roller group 1 29; crushing roller group 1 29 and crushing roller group 2 30 are arranged obliquely, and The distance between the first 29 and the crushing roller group two 30 is larger at one end and smaller at the other end, and the end with the larger distance is the feeding end; the second crushing mechanism includ...

Embodiment 2

[0052] As a preferred embodiment of the present invention, with reference to the attached figure 1 , attached figure 2 And attached image 3 , this embodiment discloses an anti-blocking hybrid crusher, this embodiment includes:

[0053] An anti-blocking hybrid crusher, comprising a first crushing mechanism and a second crushing mechanism, the first crushing mechanism includes a bracket 21, and the bracket 21 is provided with a crushing roller group 1 29 and a crushing roller group 2 30, the crushing rollers Group 1 29 and crushing roller group 2 30 are arranged side by side by multiple crushing rollers 24, crushing roller group 2 30 is arranged above crushing roller group 1 29; crushing roller group 1 29 and crushing roller group 2 30 are arranged obliquely, and The distance between the first 29 and the crushing roller group two 30 is larger at one end and smaller at the other end, and the end with the larger distance is the feeding end; the second crushing mechanism includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com