Quantifying device and cooking utensil

A quantitative device and cooking utensil technology, applied in the field of kitchen utensils, can solve problems affecting the quality of rice cooking, affecting weighing accuracy, sensor deformation, etc., to achieve the effect of ensuring good fit, optimizing appearance, and increasing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

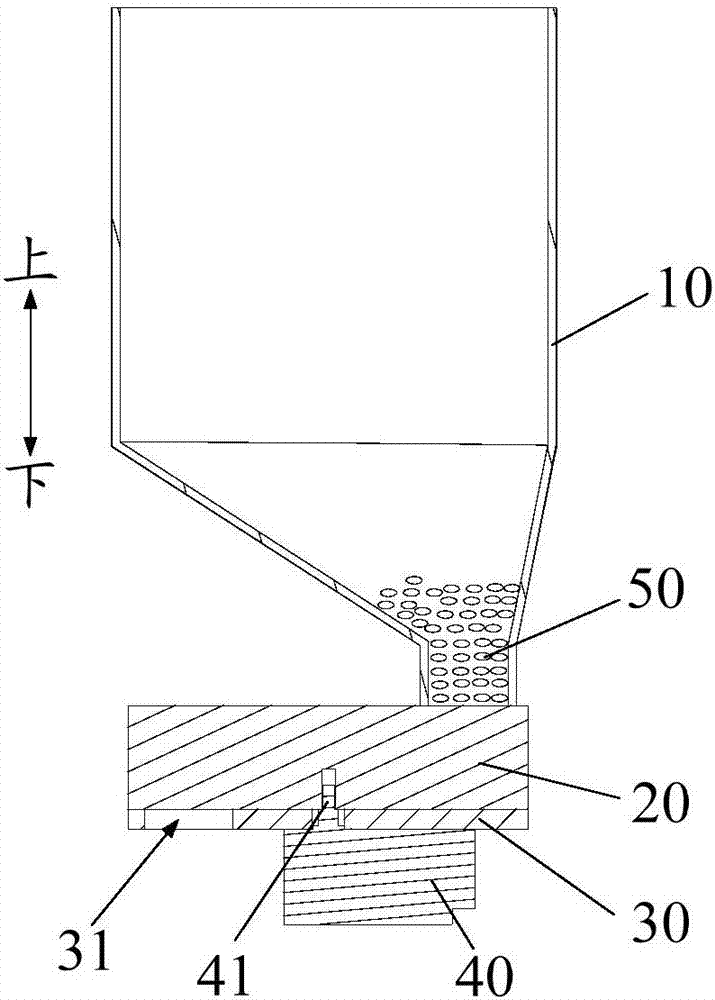

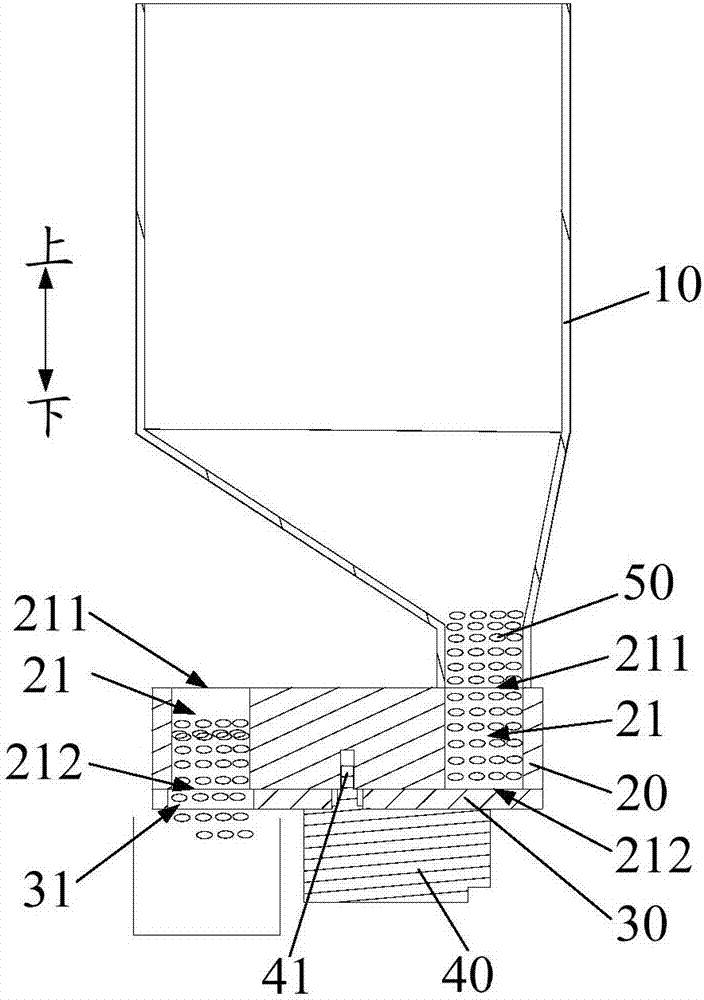

[0052] Quantitative block 20 is cylindrical, and can rotate along the central axis of quantitative block 20, as Figure 5 and Figure 7 Shown; The shield 30 is a circular baffle, such as Figure 6 shown.

[0053] The quantity of quantitative tank 21 is multiple, as Figure 5 and Figure 7 As shown, wherein, when the discharge port 212 of any one of the multiple quantitative tanks 21 is connected to the feed port 31 , the feed port 211 of at least one of the remaining quantitative tanks 21 is connected to the discharge port 11 .

[0054] Preferably, as Figure 5 and Figure 7 As shown, there are two quantitative grooves 21 , and the two quantitative grooves 21 are symmetrically distributed on the quantitative block 20 . Wherein, quantitative groove 21 is strip-shaped quantitative groove 21, and strip-shaped quantitative groove 21 bends and is arc-shaped, as Figure 5 and Figure 7 shown.

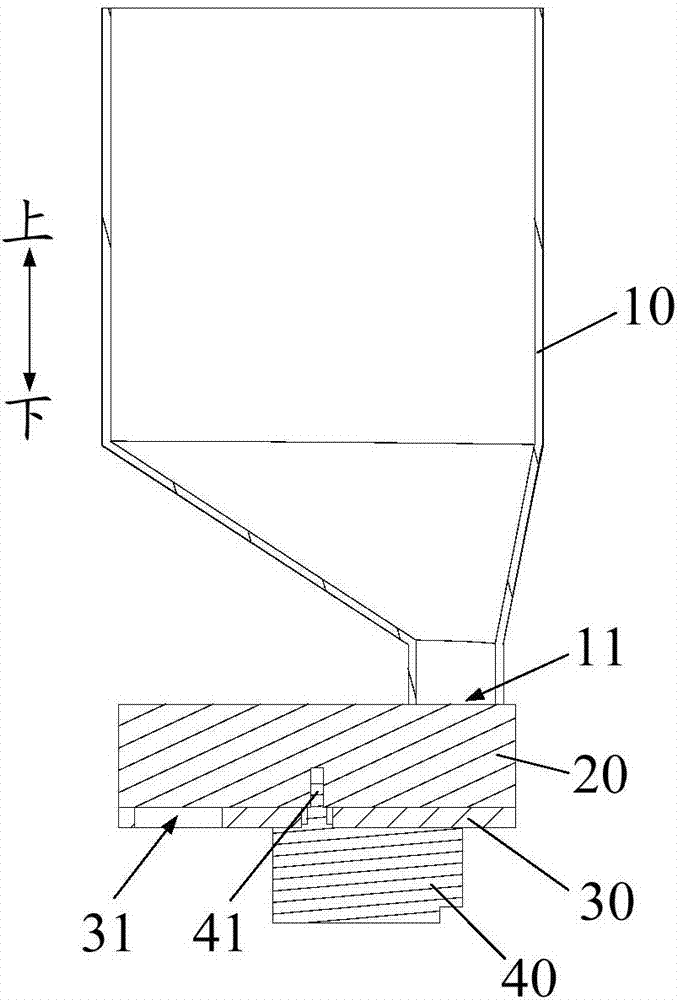

[0055] Further, as Figure 1 to Figure 3 As shown, the quantitative block 20 is...

Embodiment 2

[0066] Embodiment two (not shown in the figure)

[0067] The difference from Embodiment 1 is that there is only one quantitative tank 21 .

[0068] The specific working principle of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

[0069] Since the volume of the quantitative tank 21 is fixed, the purpose of quantitative feeding can also be achieved.

Embodiment 3

[0070] Embodiment three (not shown in the figure)

[0071] The difference from Embodiment 1 is that there are multiple quantitative grooves 21, and the sizes of the multiple quantitative grooves 21 are not exactly the same.

[0072] The specific working principle of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

[0073] Among the multiple quantitative tanks 21, some quantitative tanks 21 with relatively large sizes can be designed, and some quantitative tanks 21 with relatively small sizes can be designed.

[0074] In this way, quantitative grooves 21 of different sizes can be combined to form more quality combinations, thereby satisfying different demands of different users. Since the size of each quantitative tank 21 is fixed, the quality of the material 50 that can be stored and discharged by each quantitative tank 21 is also fixed, so the purpose of the present invention can also be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com