Bottle stopper of chemical reagent bottle

A technology for chemical reagents and bottle stoppers, which is applied in the field of bottle stoppers of chemical reagent bottles, can solve the problems of inner cap damage, difficult opening, reagent pollution, etc., and achieves the effect of easy opening and cap closing, ensuring tightness and strong tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

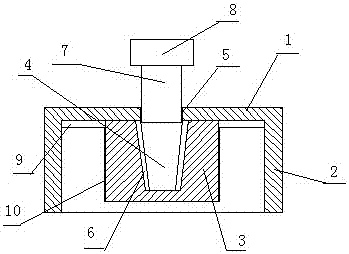

[0010] Below in conjunction with accompanying drawing, the present invention is further described:

[0011] As shown in the accompanying drawings, a bottle stopper of a chemical reagent bottle is provided with a plastic cover, the plastic cover is composed of a circular cover plate 1 and a cover plate 2, the upper end of the cover plate 2 is closed by the circular cover plate 1, The inner side of the sleeve plate 2 is provided with an internal thread that matches the external thread of the bottle mouth of the chemical reagent bottle, and it is characterized in that an elastic rubber plug 3 is provided in the middle below the circular cover plate 1 of the plastic cover, and the elastic rubber plug 3 The upper end of the upper end is connected with the lower end of the circular cover plate 1, and the lower end of the circular cover plate 1 is wrapped by the sleeve plate 2 of the plastic cover. The diameter of the elastic rubber plug 3 is smaller than the inner diameter of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com