Chili sauce making equipment

A technology of chili sauce and equipment, which is applied in the field of sauce production equipment, can solve the problems of uneven chopping, difficulty in chopping chili peppers thoroughly, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

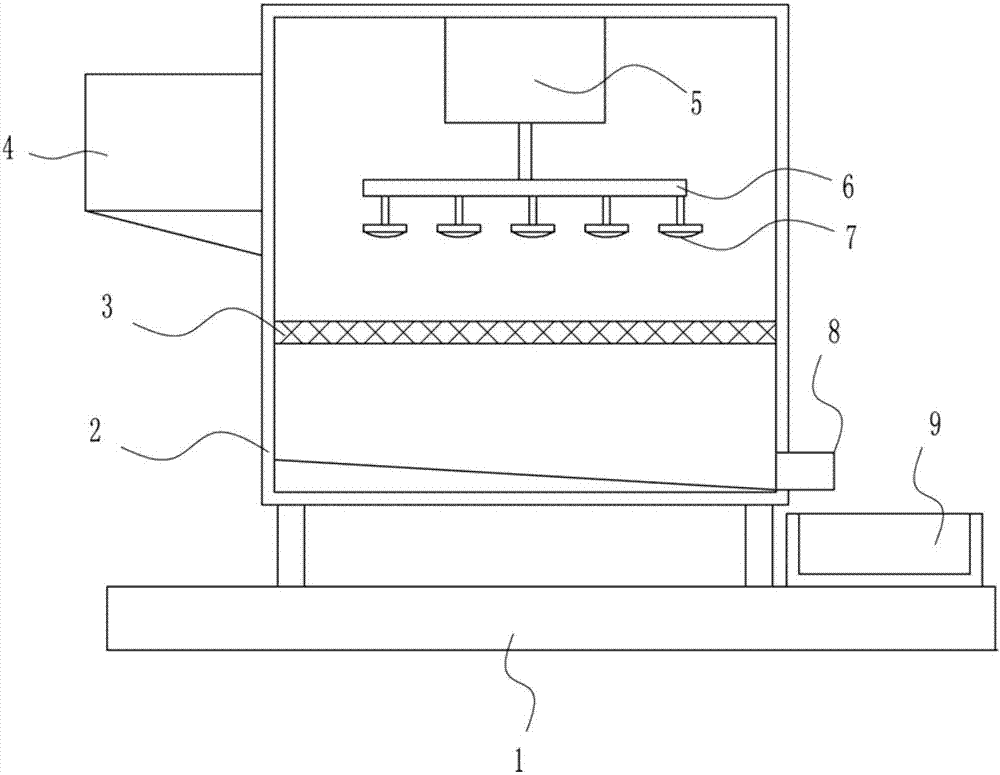

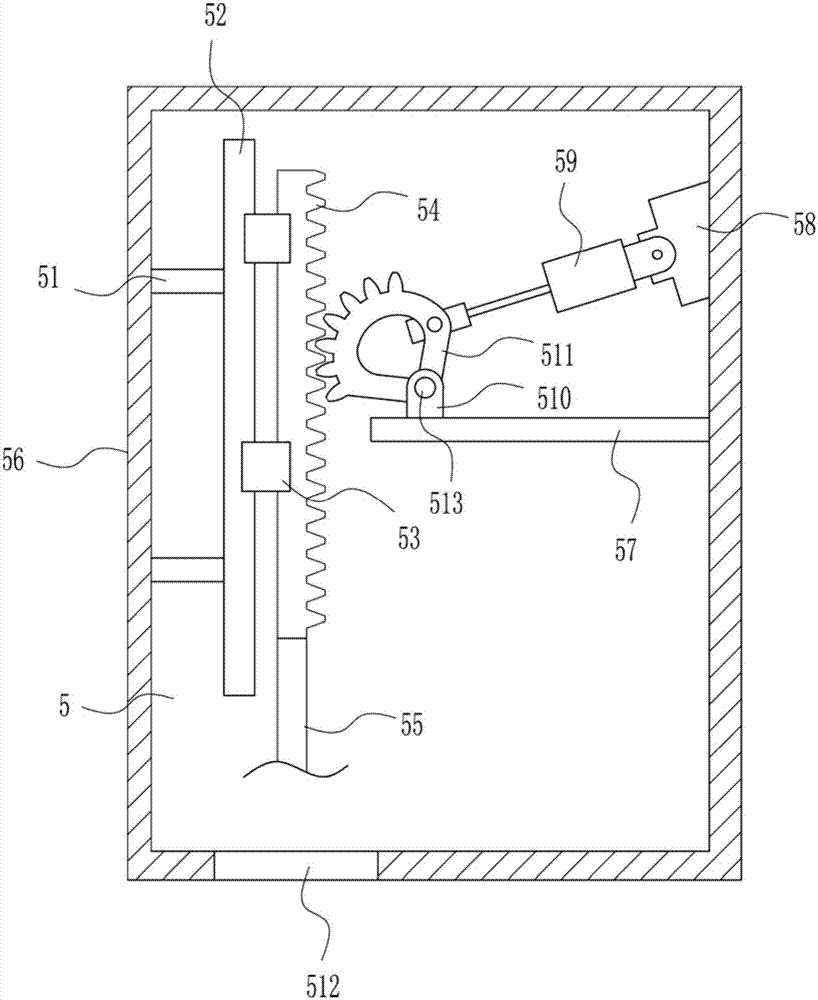

[0034] A kind of equipment for making chili sauce, such as Figure 1-5 As shown, it includes a base plate 1, a first box body 2, a screen plate 3, a feeding device 4, a lifting device 5, a mounting plate 6, a cutter 7, a discharge pipe 8 and a collection frame 9, and the top of the base plate 1 is welded in the middle The first box body 2, the feeding device 4 is welded on the left side outside the first box body 2, the lifting device 5 is connected to the top of the first box body 2 through bolt connection, and the mounting plate 6 is welded on the bottom of the lifting device 5, and the installation The bottom of the plate 6 is evenly welded with a cutter 7, the left and right walls of the first box 2 are connected with a mesh plate 3 by bolt connection, the outer right bottom of the first box 2 is welded with a discharge pipe 8, and the top of the bottom plate 1 A collecting box 9 is placed on the right side.

Embodiment 2

[0036] A kind of equipment for making chili sauce, such as Figure 1-5 As shown, it includes a base plate 1, a first box body 2, a screen plate 3, a feeding device 4, a lifting device 5, a mounting plate 6, a cutter 7, a discharge pipe 8 and a collection frame 9, and the top of the base plate 1 is welded in the middle The first box body 2, the feeding device 4 is welded on the left side outside the first box body 2, the lifting device 5 is connected to the top of the first box body 2 through bolt connection, and the mounting plate 6 is welded on the bottom of the lifting device 5, and the installation The bottom of the plate 6 is evenly welded with a cutter 7, the left and right walls of the first box 2 are connected with a mesh plate 3 by bolt connection, the outer right bottom of the first box 2 is welded with a discharge pipe 8, and the top of the bottom plate 1 A collecting box 9 is placed on the right side.

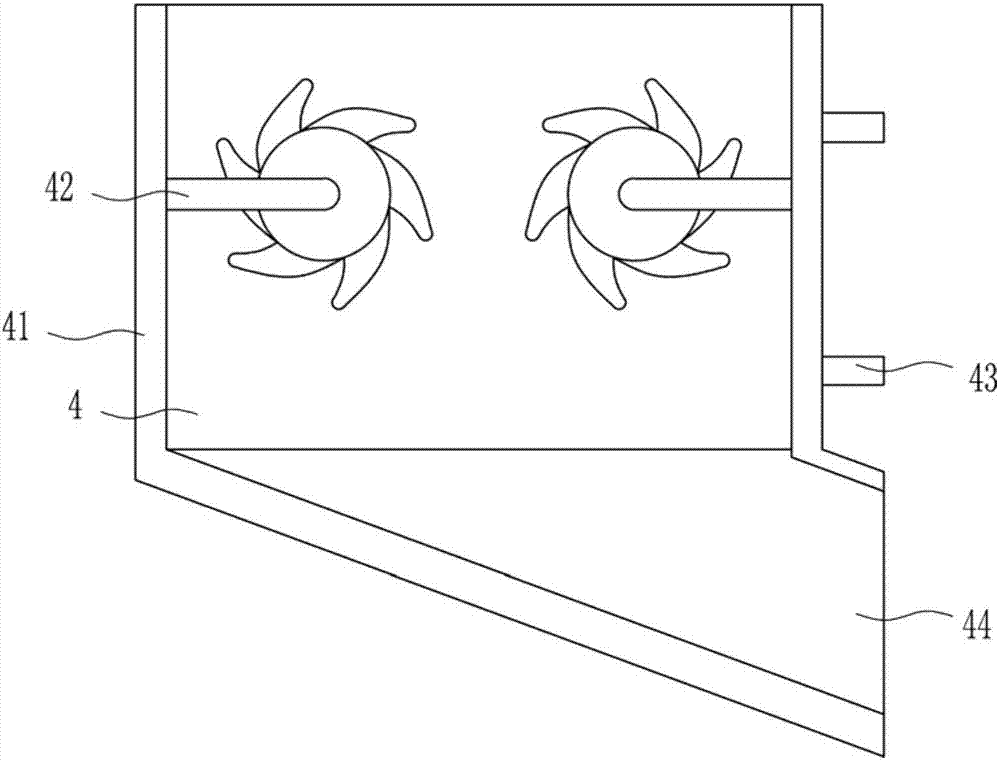

[0037] The feeding device 4 includes a second box body 41, an ...

Embodiment 3

[0039] A kind of equipment for making chili sauce, such as Figure 1-5 As shown, it includes a base plate 1, a first box body 2, a screen plate 3, a feeding device 4, a lifting device 5, a mounting plate 6, a cutter 7, a discharge pipe 8 and a collection frame 9, and the top of the base plate 1 is welded in the middle The first box body 2, the feeding device 4 is welded on the left side outside the first box body 2, the lifting device 5 is connected to the top of the first box body 2 through bolt connection, and the mounting plate 6 is welded on the bottom of the lifting device 5, and the installation The bottom of the plate 6 is evenly welded with a cutter 7, the left and right walls of the first box 2 are connected with a mesh plate 3 by bolt connection, the outer right bottom of the first box 2 is welded with a discharge pipe 8, and the top of the bottom plate 1 A collecting box 9 is placed on the right side.

[0040] The feeding device 4 includes a second box body 41, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com