Method and apparatus of identifying welding seams of welding object

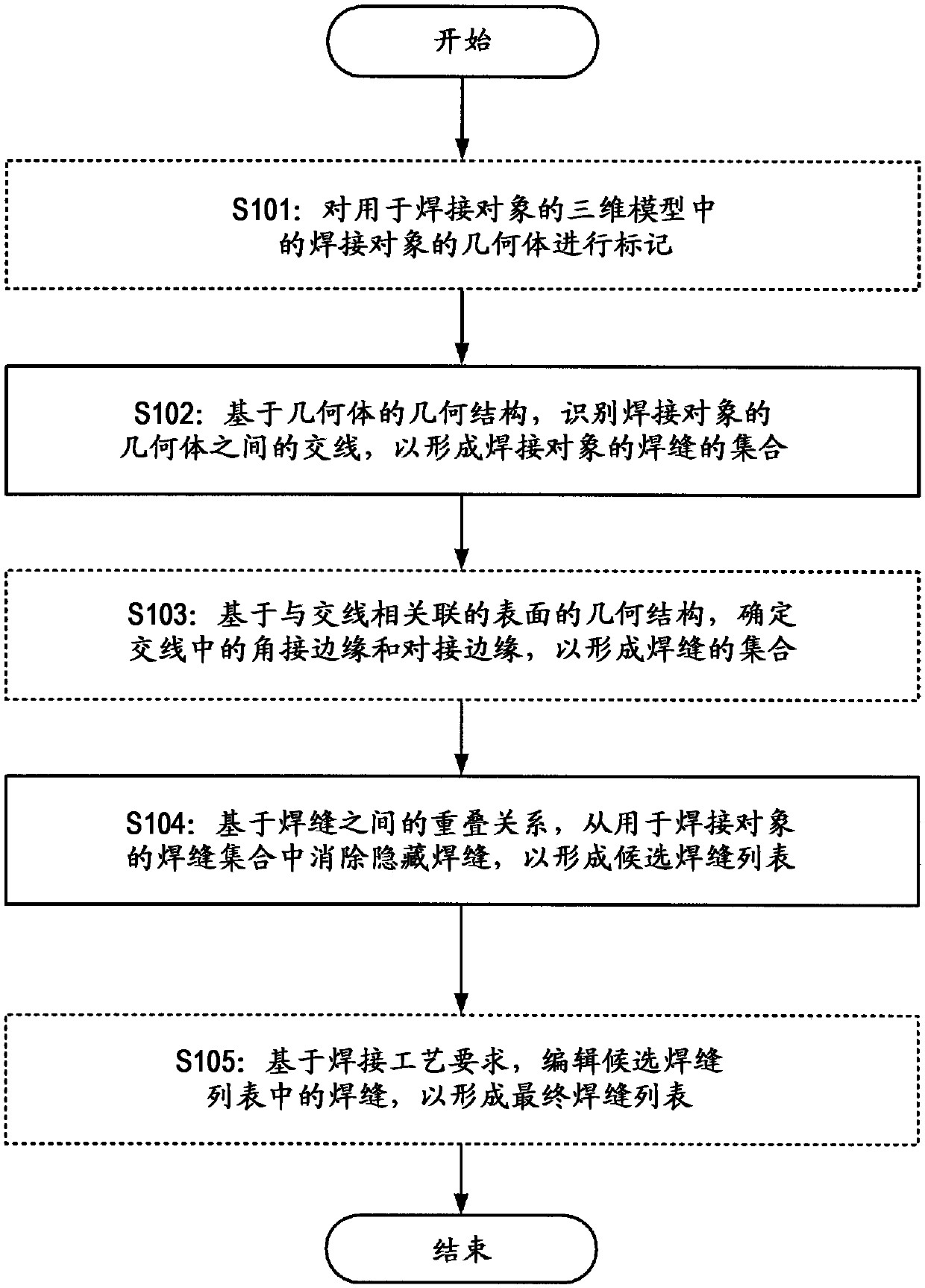

一种对象、焊接工艺的技术,应用在焊接设备、焊接配件、电弧焊设备等方向,达到自动水平提高、生产成本降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

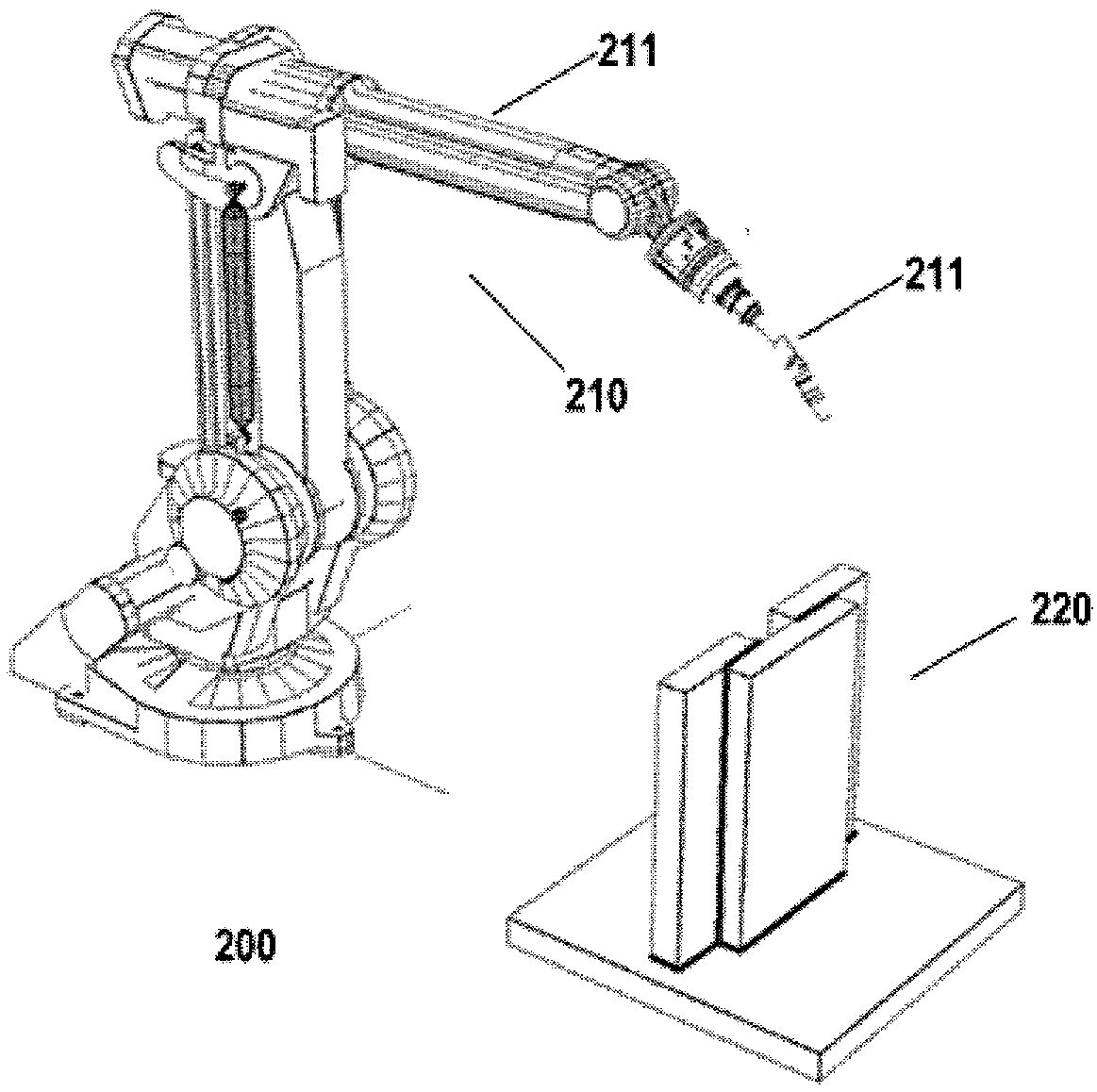

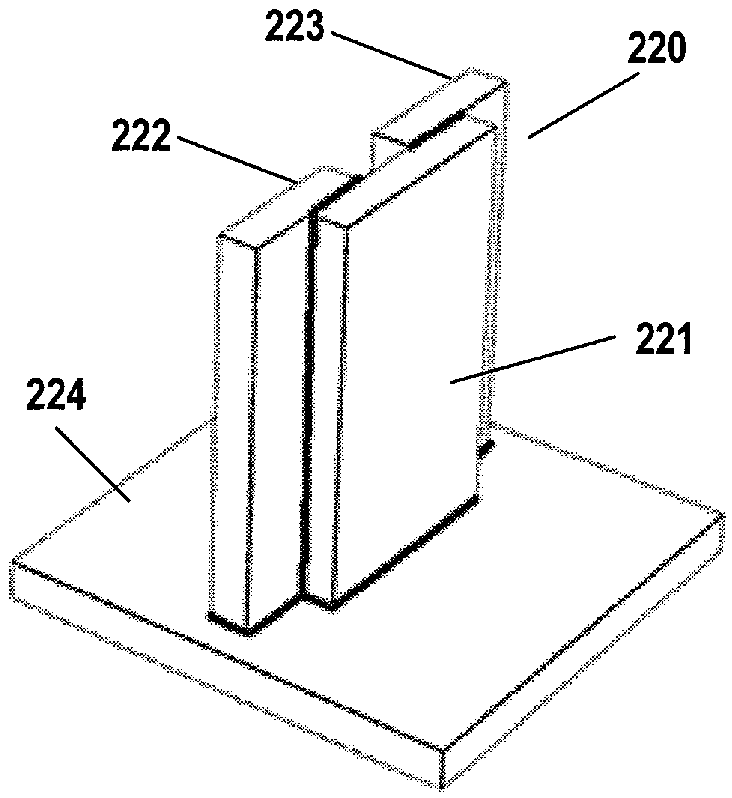

[0023] Hereinafter, solutions provided in the present disclosure will be described in detail through embodiments with reference to the accompanying drawings. It should be understood that these embodiments are presented only to enable those skilled in the art to better understand and implement the present disclosure, and are not intended to limit the scope of the present disclosure in any way.

[0024] Generally, all terms used in the claims are to be interpreted according to their ordinary meaning in the technical field, unless explicitly defined otherwise herein. All references to "a / an / the / the [element, device, component, means, step, etc.]" are to be construed openly as referring to at least An instance, unless expressly stated otherwise, does not exclude a plurality of such devices, components, means, units, steps etc. Furthermore, the indefinite article "a" or "an" used herein does not exclude a plurality of such steps, units, modules, devices and objects etc.

[0025] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com