Full cross-section tunneling machine duct piece fast unloading and storage device

A technology of tunnel boring machine and storage device, which is applied to tunnels, tunnel linings, shaft equipment, etc., can solve the problems that segments cannot be removed, affect the efficiency of train marshalling and other processes, and achieve small occupied space, convenient operation, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

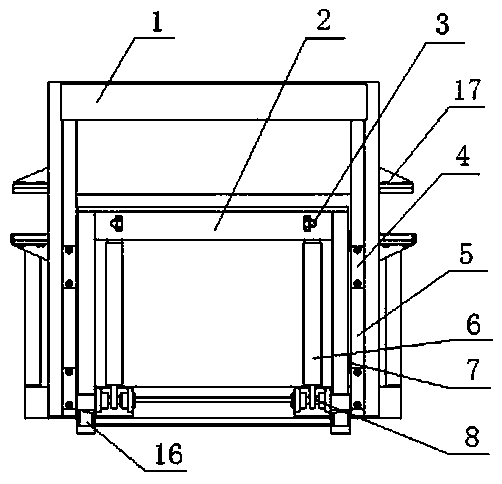

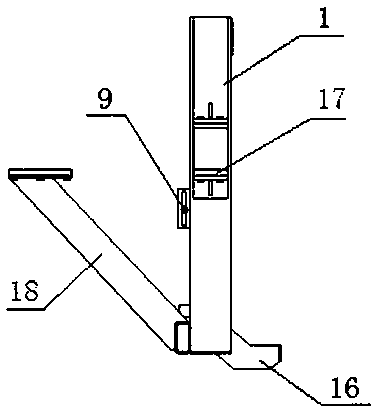

[0016] see figure 1 and figure 2 , a full-section tunnel boring machine segment fast unloading storage device of the present invention is characterized in that it includes a support frame 1, a lifting frame 2, a guide rail 5 and an oil cylinder 6, and the inner sides of the two vertical sides of the n-shaped support frame 1 are respectively installed The guide rail 5 and the outer sides of the two vertical sides of the lifting frame 2 are slidably connected in the groove of the guide rail 5 through rollers 7; the upper end of the oil cylinder 6 is connected to the support frame 1, and the lower end of the oil cylinder 6 is connected to the lifting frame 2. 2. The front side of the lower end is provided with lifting feet 16; the support frame 1 is provided with a proximity switch 9 for controlling the up and down position of the lifting frame. During work, the stroke of the piston rod of the oil cylinder 6 and the proximity switch 9 are controlled to control the sliding posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com