Efficient plant fiber separator

A plant fiber and separator technology is applied in the field of high-efficiency plant fiber separators, which can solve the problems of low output and low efficiency of manual hemp stripping, and achieve the effects of good separation effect, high production efficiency and improved separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

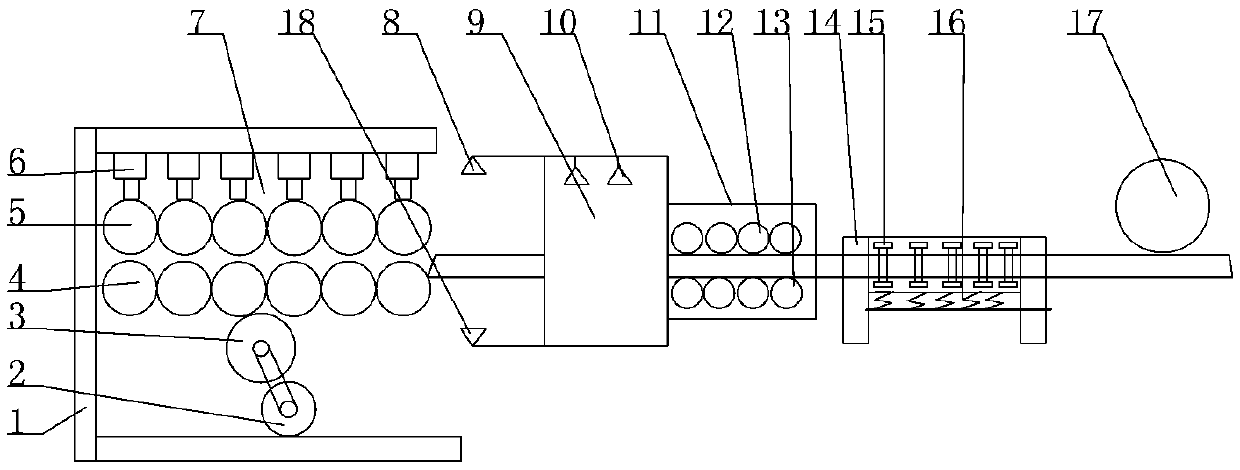

[0026] Implementation case one: a kind of high-efficiency plant fiber separator, comprises successively according to processing sequence, rolling separation device 7, softening device, steam heating device 9, secondary rolling device 11, vibration separation device and discharge device 17, all The rolling and separating device 7 includes a roller support 1, and the roller support 1 is provided with several roller sets, and the roller sets are composed of an upper roller set 5 and a lower roller set 4 correspondingly arranged up and down, The lower end of the bottom roller wheel set 4 is connected with a transmission gear 3,

[0027] Further, a bridge gear 2 is arranged below the transmission gear 3, and the bridge gear 2 is driven by a driving device arranged below.

[0028] Further, the described upper roller wheel group 5 is provided with an electric telescopic rod group 6, and the described electric telescopic rod group 6 is fixed on the roller support 1.

[0029] Further,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com