Tool clamping device for wood engraving machine

A tool clamping and engraving machine technology, which is applied in the fields of engraving and decorative art, can solve problems such as tool breakage, lower production efficiency, troublesome tool replacement, etc., and achieve the effects of convenient replacement, improved work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

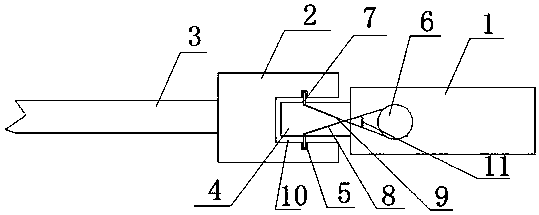

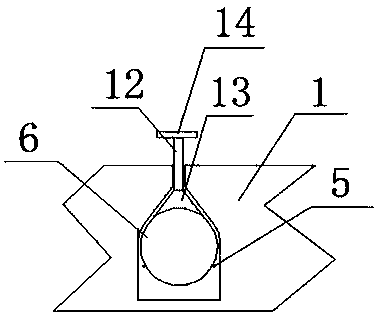

[0014] The present invention will be further described below in conjunction with the drawings and embodiments.

[0015] figure 1 , figure 2 In, a wood carving machine tool clamping device includes a rotating shaft 1 and a cutter. The cutter includes a cutting edge 3 and a cutter head 2 connected to each other. The cutter head 2 is connected with the rotating shaft 1, and the rotating shaft 1 has a transmission block 4 and a cutter head 2 protruding from it. A groove 10 adapted to the transmission block 4 is opened inward, and the transmission block 4 is provided with a first locking rod 8 and a second locking rod 9, which intersect each other, and the first locking rod 8 and the second locking rod 9 Rotatingly connected, one ends of the first locking rod 8 and the second locking rod 9 both extend into the rotating shaft 1, and the first locking rod 8 and the second locking rod 9 are provided with a limit block at one end located in the transmission block 4 7. The cutter head 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com