Workpiece main shaft capable of automatically dividing and clamping

An automatic indexing, workpiece spindle technology, applied in electric components, metal processing mechanical parts, driving devices, etc., can solve the problems of unsatisfactory braking effect, increased rotational inertia, insufficient braking force, etc., and achieve good braking effect. , strong thrust, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

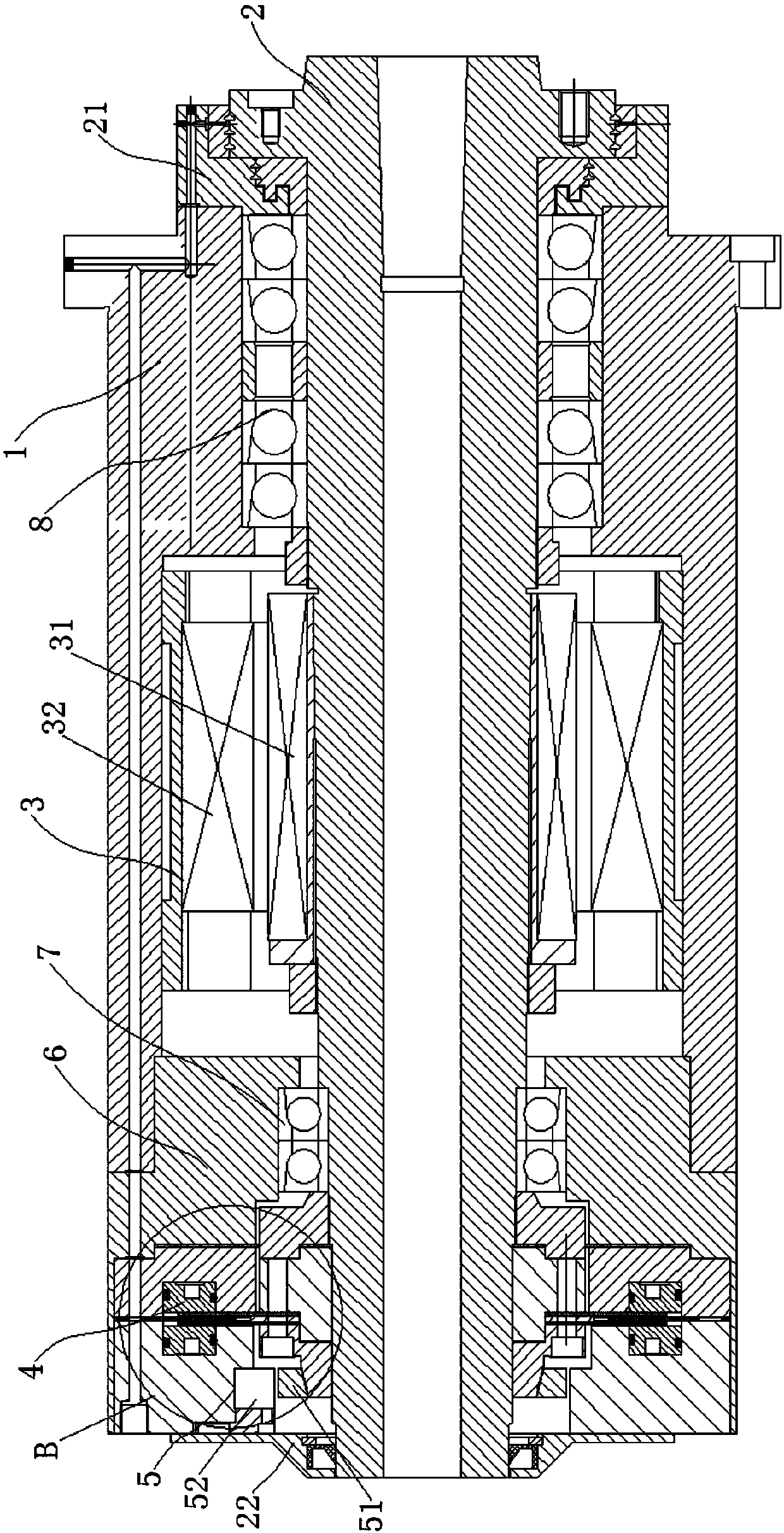

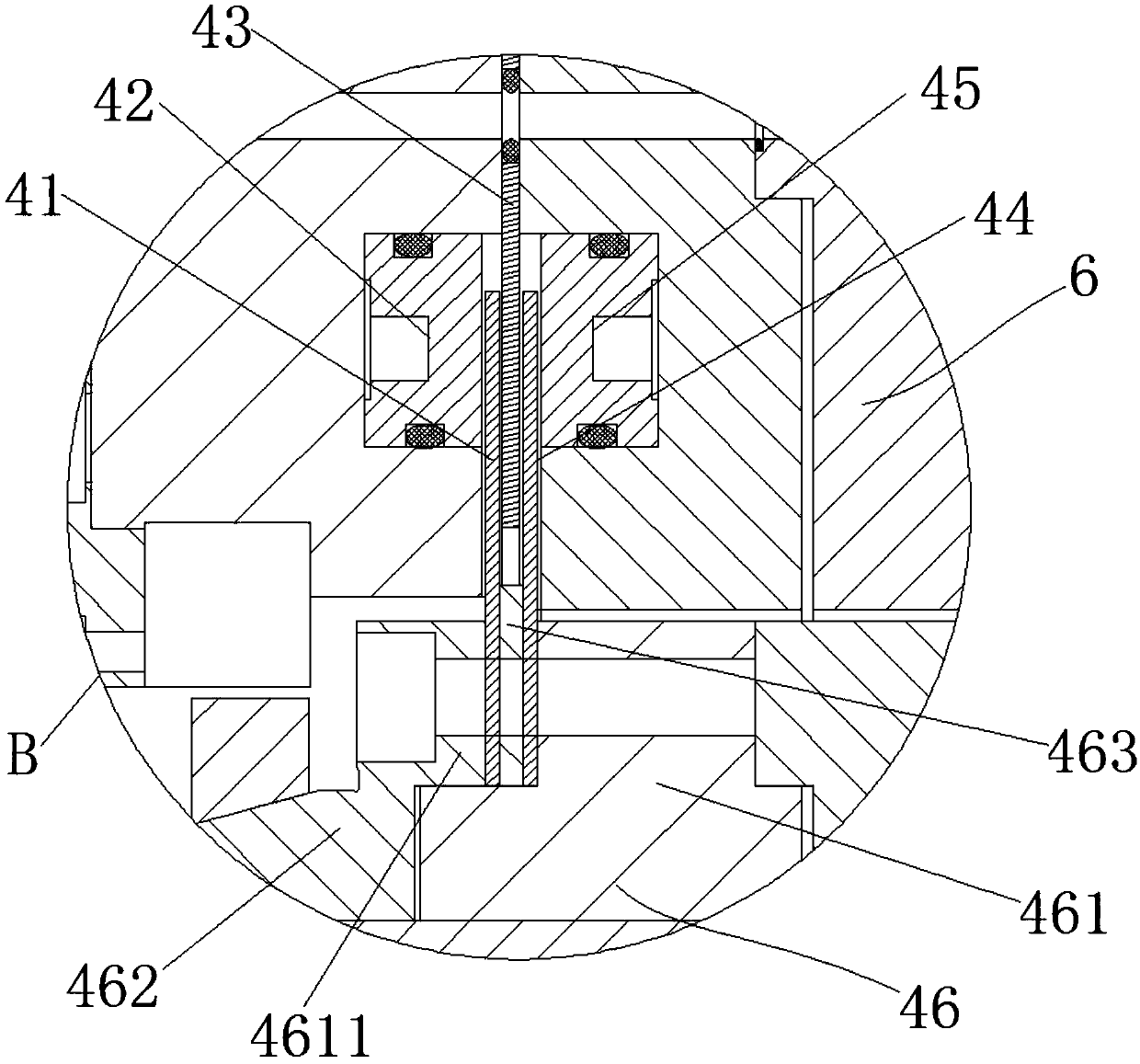

[0031] Such as Figure 1 ~ Figure 3 As shown, a workpiece spindle that can be automatically indexed and clamped according to the present invention includes a shaft sleeve 1, a shaft core 2, a motor 3, a clamping assembly 4 and an encoder assembly 5, and the shaft core 2 can pivotally Set in the shaft sleeve 1, the motor 3 is in transmission connection with the shaft core 2, and the motor 3 drives the shaft core 2 to rotate in the shaft sleeve 1. The clamping assembly 4 includes a brake disc 41, a first brake pad 42 and a first cylinder 43, the brake disc 41 is fixedly connected to the bushing 1, the first brake pad 42 is fixedly connected to the shaft core 2, the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com