Manufacturing method of rustproof anticorrosion milling machine water tank

A technology of anti-rust, anti-corrosion, and manufacturing method, which is applied in the field of water tank anti-rust, can solve problems such as difficult-to-immerse tank pretreatment, and achieve the effects of shortening manufacturing time, ensuring reliability, and enhancing anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

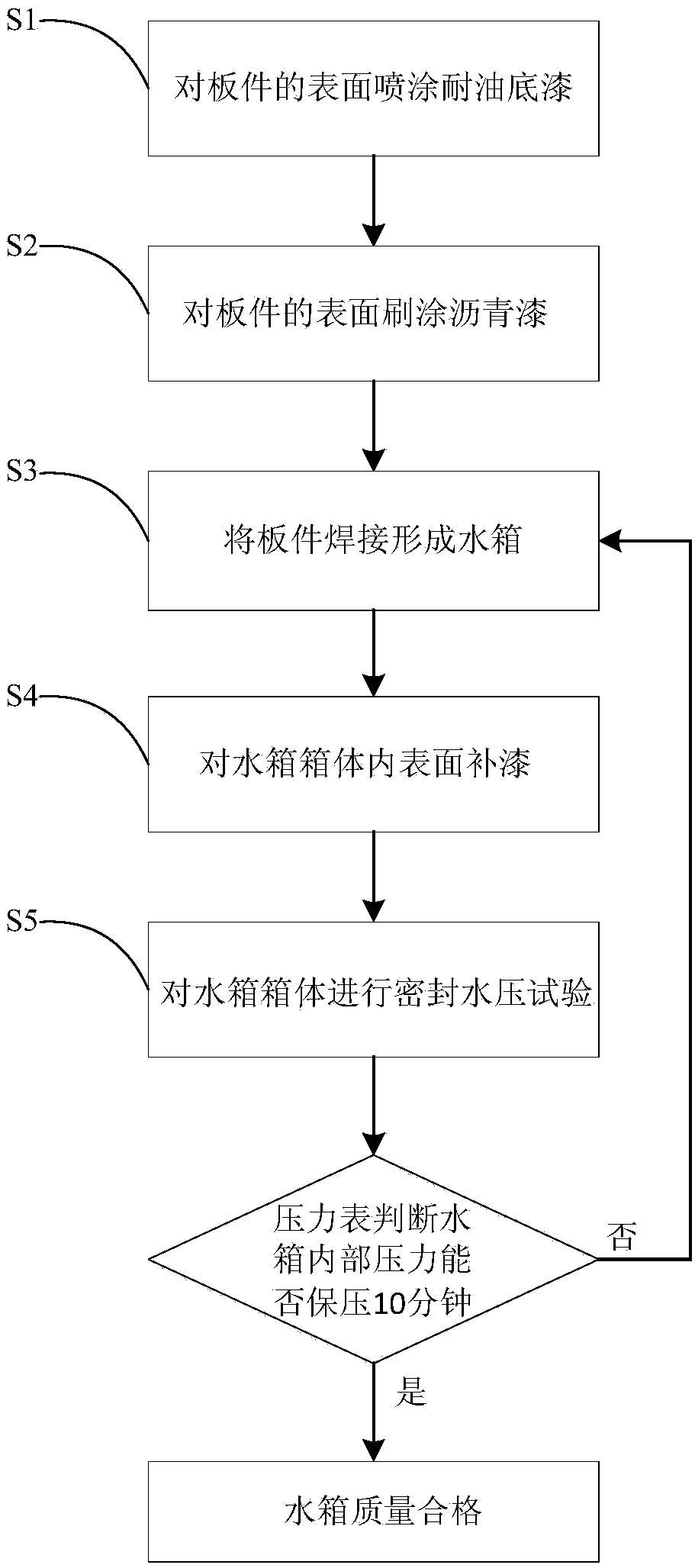

[0032] The invention provides a method for manufacturing an antirust and anticorrosion milling machine water tank, such as figure 1 Shown, the manufacture method of this water tank comprises the following steps:

[0033] S0, perform shot blasting on the plate:

[0034] Before the water tank body is welded, each plate is subjected to shot blasting treatment through a shot blasting machine, including shot blasting cleaning and shot blasting strengthening, to remove impurities such as oxide skin on the surface of the plate to improve the appearance quality, and to use high-speed motion (such as a speed of 60 ~110m / s) projectile flow continuously impacts the surface of the reinforced workpiece, which can improve the fatigue fracture resistance of materials or parts, prevent fatigue failure, plastic def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com