a paint sprayer

The technology of a paint spraying machine and a spraying head is applied in the directions of spraying device, pretreatment surface, and device for coating liquid on the surface, etc. It can solve the problems of uneven spraying, rising production cost, complicated modification of spraying equipment structure, etc., and achieve uniform spraying. Appropriate and fast spray paint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below.

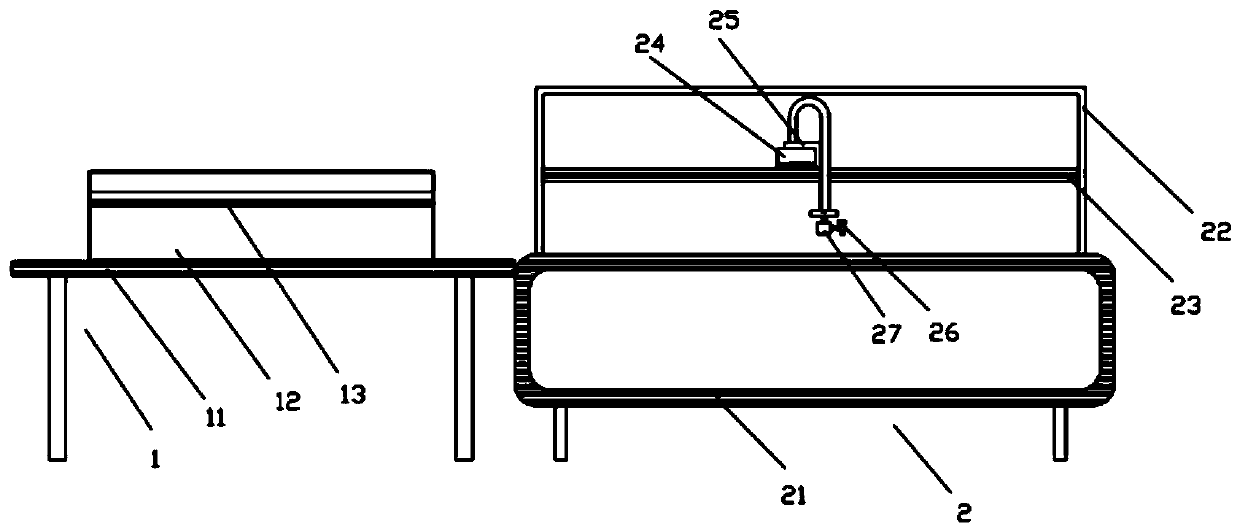

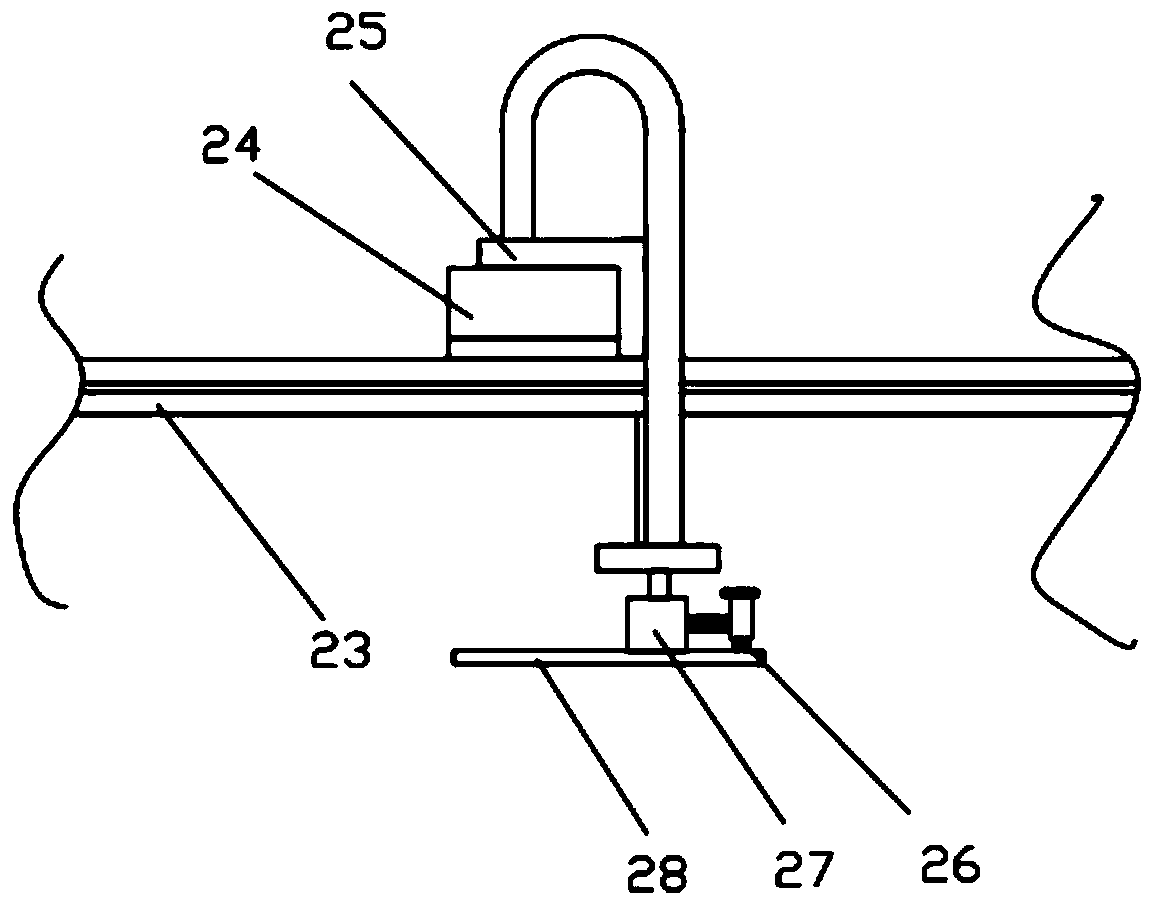

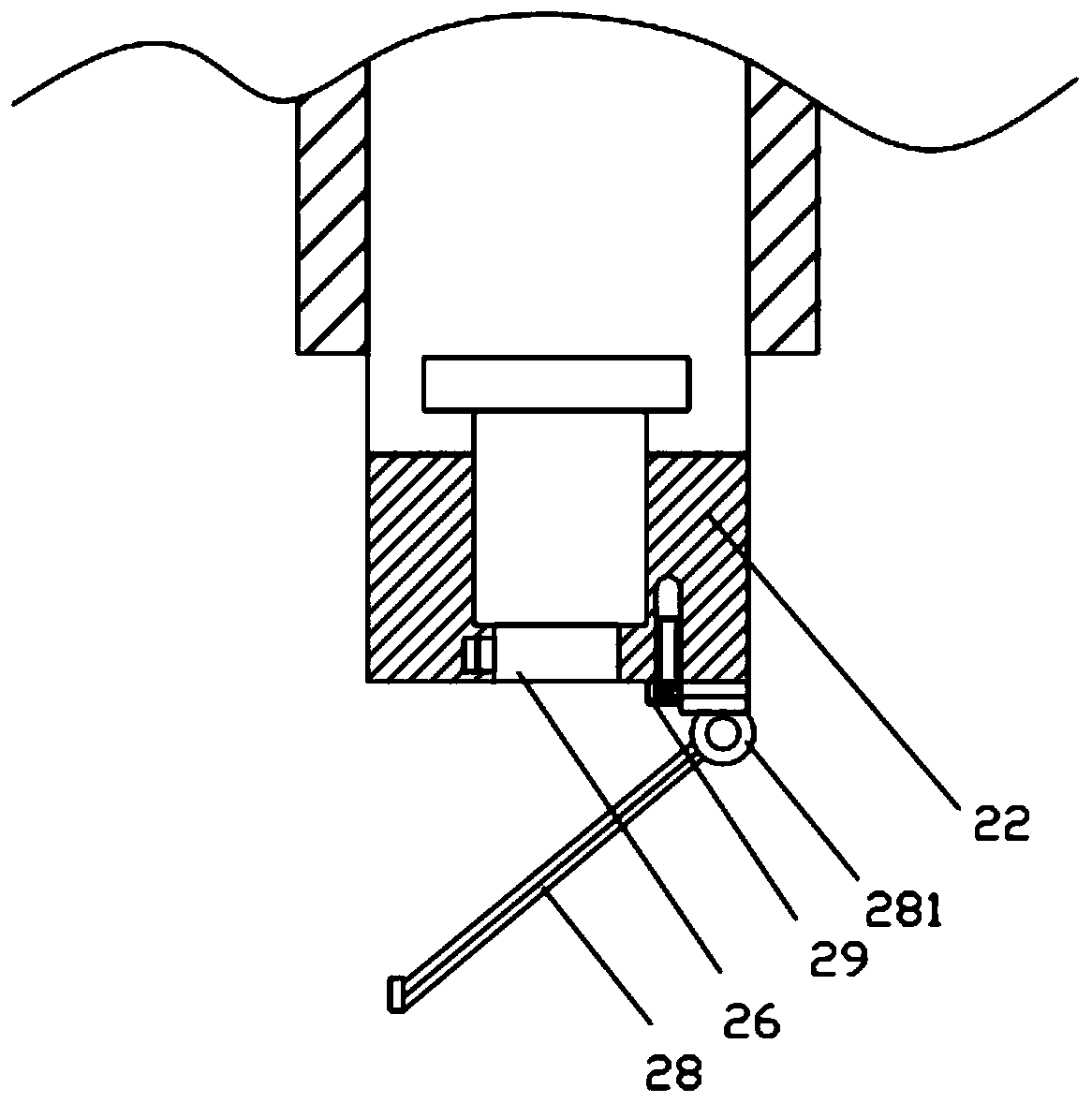

[0016] A paint spraying machine, comprising a drying workbench 1 and a paint spraying device 2, wherein a conveyor belt 21 is installed on the paint spraying device 2, and a paint spraying workbench 22 is arranged on the conveyor belt 21. Products are transferred on the conveyor belt 21, and the conveyor belt 21 stops rotating, and now the paint spraying head 26 moves forward and backward along the longitudinal rail 24 through the sliding plate 25, and the longitudinal rail 24 is located above the horizontal rail 23 and moves left and right along the horizontal rail 23, when the paint spraying head 26 adjusts its position, it starts The surface of the product is sprayed, and a spray angle control board 28 is arranged below the paint spray head 26. The paint spray angle control plate 28 is installed on the bottom of the connection module 27 through a rotating shaft 281, and one side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com