Protective element with drainage, for connecting to a concrete element of a tunnel extension

A technology for protecting elements and tunnel structures, applied in tunnels, building components, tunnel linings, etc., can solve problems such as unrealizable structures, and achieve the effect of high sealing effect and simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

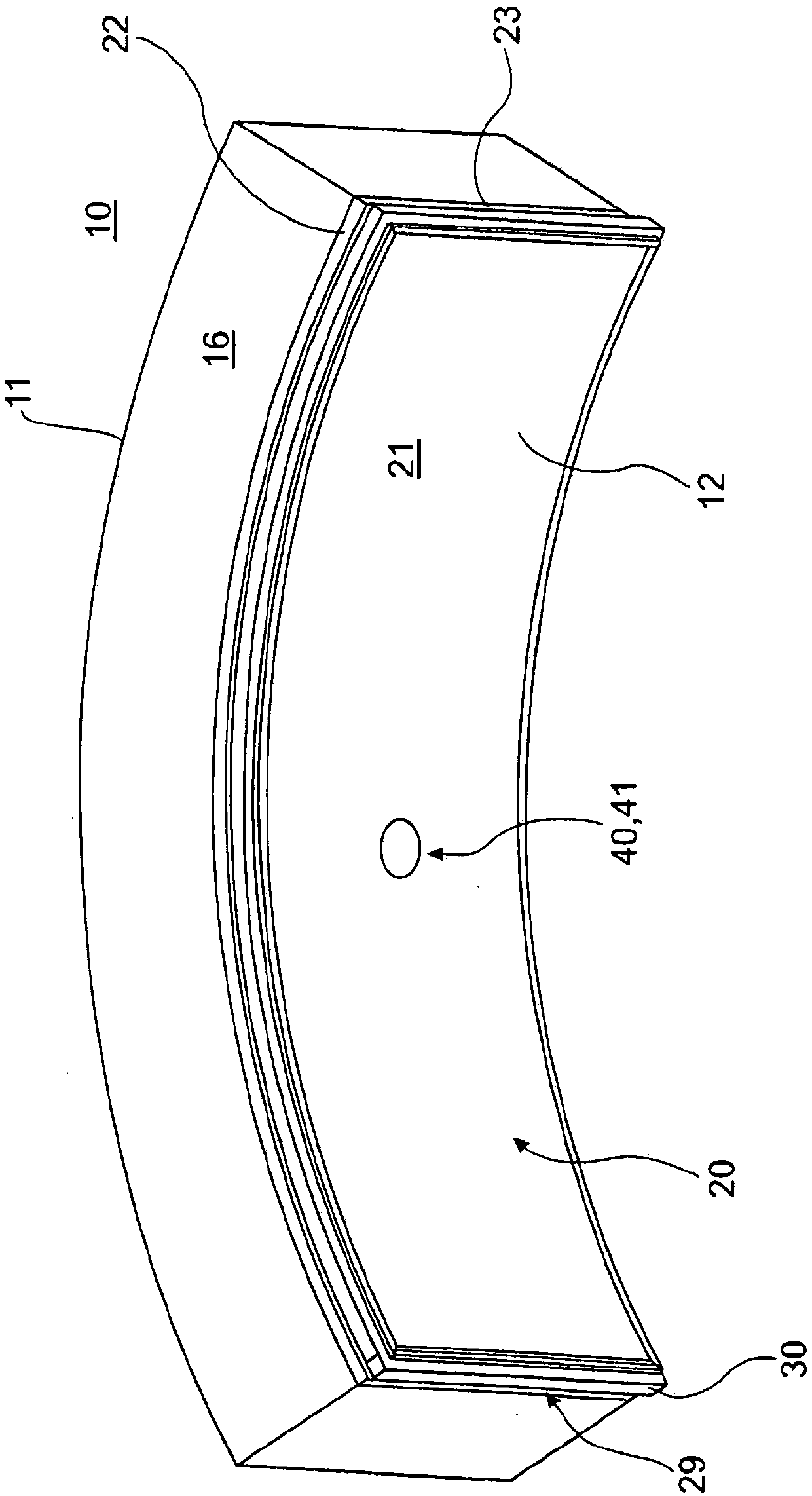

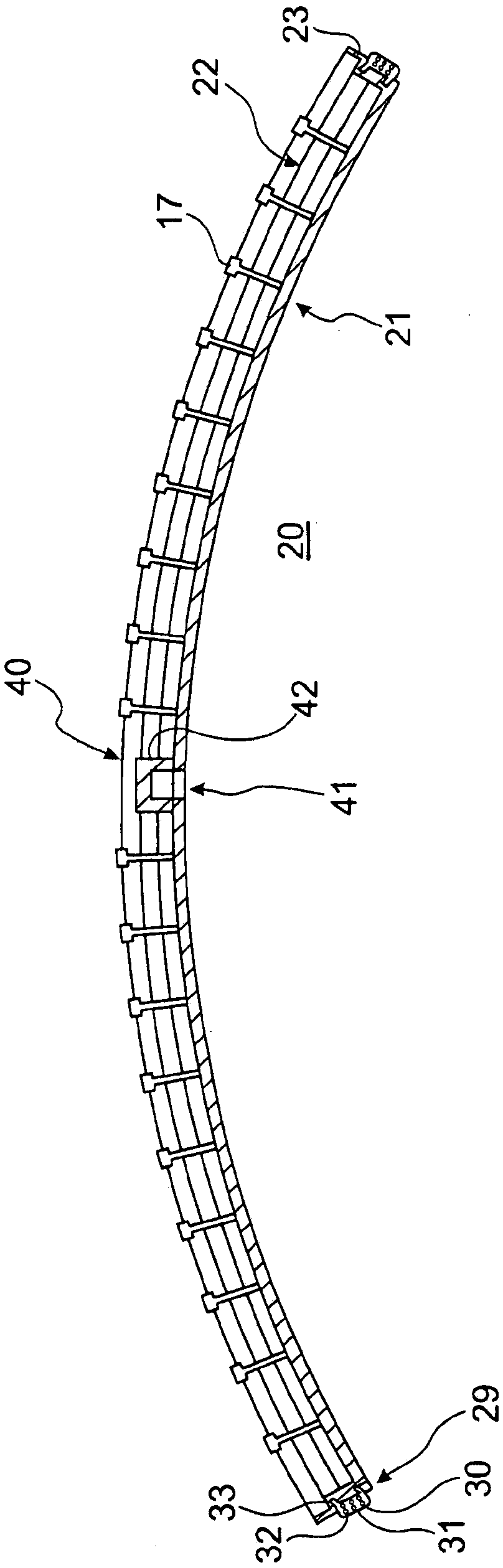

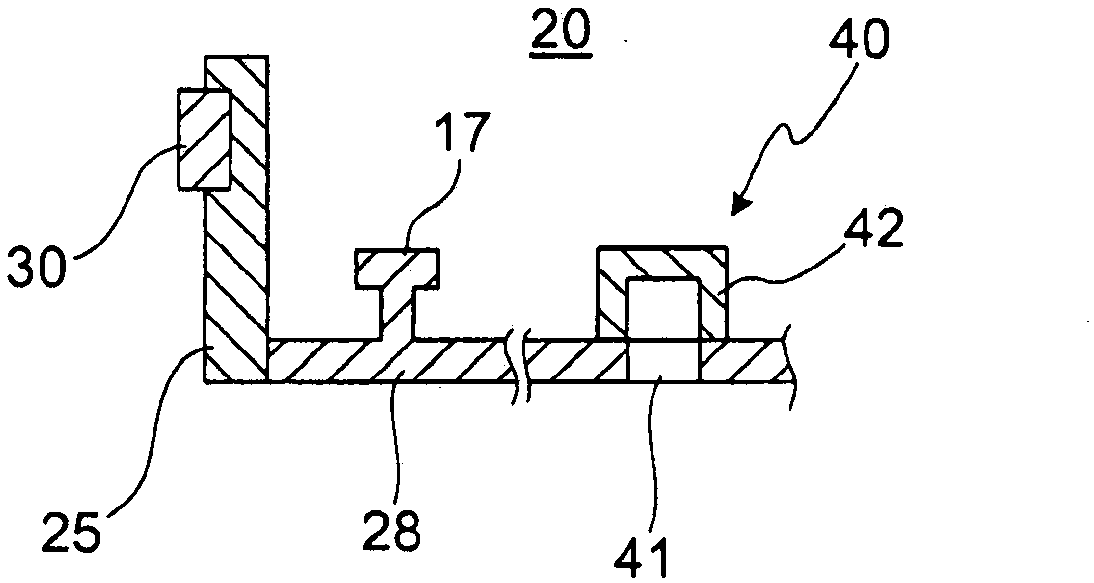

[0044] Concrete element 10 ( figure 1 ) is the arcuate section of the tunnel structure (the Chubin tube). The arcuate section has a convex upper side 11 and an underside 12 arranged opposite it (at the figure 1 covered by the protective element 20). A protective element 20 is arranged on the inner side 12 of the concrete element. In this embodiment, the protective element 20 has a bottom section 21 and wall sections 22 , 23 . A receiving region 29 is provided on the wall sections 22 , 23 , in which the sealing element 30 is arranged. The connection between the seal 30 and the protective element 20 takes place, for example, by injection molding.

[0045] Alternatively, the concrete element can also have only one protective element 20 (not shown) with the bottom section 21 . A seal 30 may, but need not be provided. If no seals are provided, the seams between the individual protective elements 20 of the concrete element 10 are welded to each other.

[0046] as in figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com