Oil transfer pipeline oil leakage detection system based on fiber grating and work method thereof

A fiber grating and oil pipeline technology, which is applied in the field of oil leakage detection systems for oil pipelines based on fiber grating, can solve problems such as different working environments and working states, and achieve the effects of simple structure, good electrical insulation performance and good compensation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

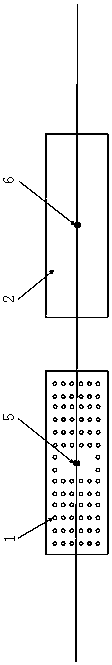

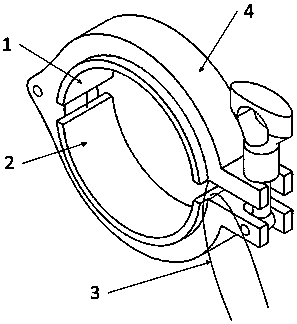

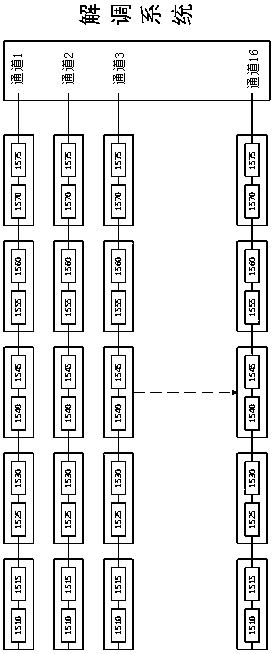

[0022] Such as figure 1 , 2 As shown, this embodiment provides a fiber grating-based oil pipeline oil leakage detection system, including a detection sensor, a multi-channel wavelength demodulator and a computer. The detection sensor is composed of a base material, a sensitive material, and a fiber grating. The above-mentioned sensitive material is composed of EPDM rubber that swells when encountering oil, and is in the shape of a long strip. The expansion of the rubber, the base material is made of EPDM rubber in a long strip shape, and the surface of the base material is covered with a layer of epoxy resin to isolate the contact with the oil. The optical fiber passes through the sensitive material and the base material, and two gratings with different wavelengths are respectively set in the middle of the sensitive material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com