Epoxy resin curing agent and synthesis method thereof

A technology of epoxy resin curing and synthesis method, which is applied in the field of epoxy resin curing agent, can solve the problems of high exothermic peak, violent reaction, strong hygroscopicity, etc., and achieve low exothermic peak temperature, simple synthesis process and high reactivity low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Weigh 103.17g of diethylenetriamine and add it into a reaction bottle equipped with a stirrer, thermometer, condensing reflux tube, dropping funnel, vacuum device, and nitrogen device, first evacuate to -0.01MPa, feed nitrogen, and start stirring , the rotation speed is controlled at 100 rpm, and 85.11 g of butyrolactam is dropped in at a constant speed through the dropping funnel, the reaction temperature is controlled at 70-80°C, and the reaction time of the dropwise addition is controlled for 3 hours. After the dropwise reaction is completed, the temperature is raised to 150-180 ℃, continue to stir and react for 2 hours, lower the temperature to 40-45 ℃, eliminate the vacuum and stop feeding nitrogen, and discharge test;

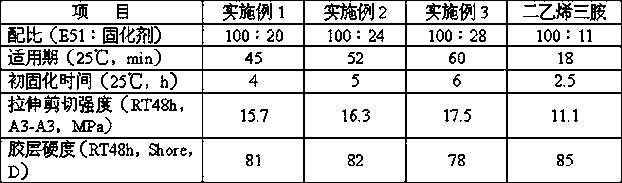

[0012] The test data is shown in the table below:

[0013] Test items

Embodiment 2

[0015] Weigh 103.17g of diethylenetriamine and add it into a reaction bottle equipped with a stirrer, thermometer, condensing reflux tube, dropping funnel, vacuum device, and nitrogen device, first evacuate to -0.01MPa, feed nitrogen, and start stirring , the rotation speed is controlled at 100 rpm, and 127.67g of butyrolactam is dropped into it at a constant speed through the dropping funnel, the reaction temperature is controlled at 70-80°C, and the dropwise reaction time is controlled for 3 hours. After the dropwise reaction is completed, the temperature is raised to 150-180 ℃, continue to stir and react for 2 hours, lower the temperature to 40-45 ℃, eliminate the vacuum and stop feeding nitrogen, and discharge test;

[0016] The test data is shown in the table below:

[0017] Test items

Embodiment 3

[0019] Weigh 103.17g of diethylenetriamine and add it into a reaction bottle equipped with a stirrer, thermometer, condensing reflux tube, dropping funnel, vacuum device, and nitrogen device, first evacuate to -0.01MPa, feed nitrogen, and start stirring , the rotation speed is controlled at 100 rpm, and 170.22 g of butyrolactam is dropped into it at a constant speed through the dropping funnel, the reaction temperature is controlled at 70-80 ° C, and the reaction time of the dropping is controlled for 3 hours. ℃, continue to stir and react for 2 hours, lower the temperature to 40-45 ℃, eliminate the vacuum and stop feeding nitrogen, and discharge test;

[0020] The test data is shown in the table below:

[0021] Test items

Example 3

Exterior

Brown yellow transparent liquid

Amine value (mgKOH / g)

514.5

Viscosity (40℃, mPa•s)

2200

[0022] Application performance testing:

[0023] The epoxy curing agent samples prepared in Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com