Flexible production line for producing paper pulp molded products

A flexible production line, pulp molding technology, applied in the stacking of objects, destacking of objects, textiles and papermaking, etc., can solve the problems of long production cycle, large space occupation area, low production efficiency, etc., and achieve the degree of mechanical automation High, reduce labor intensity, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

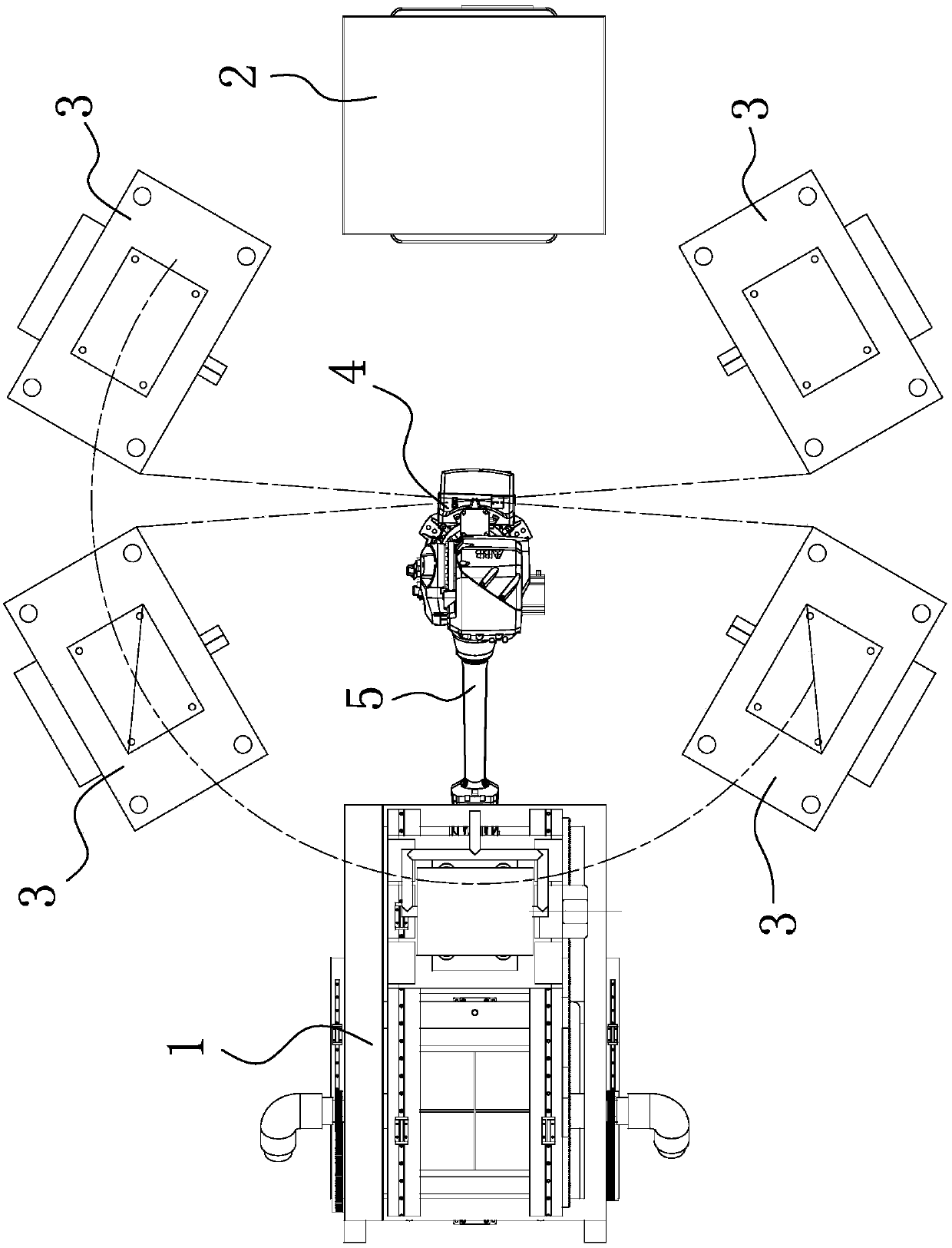

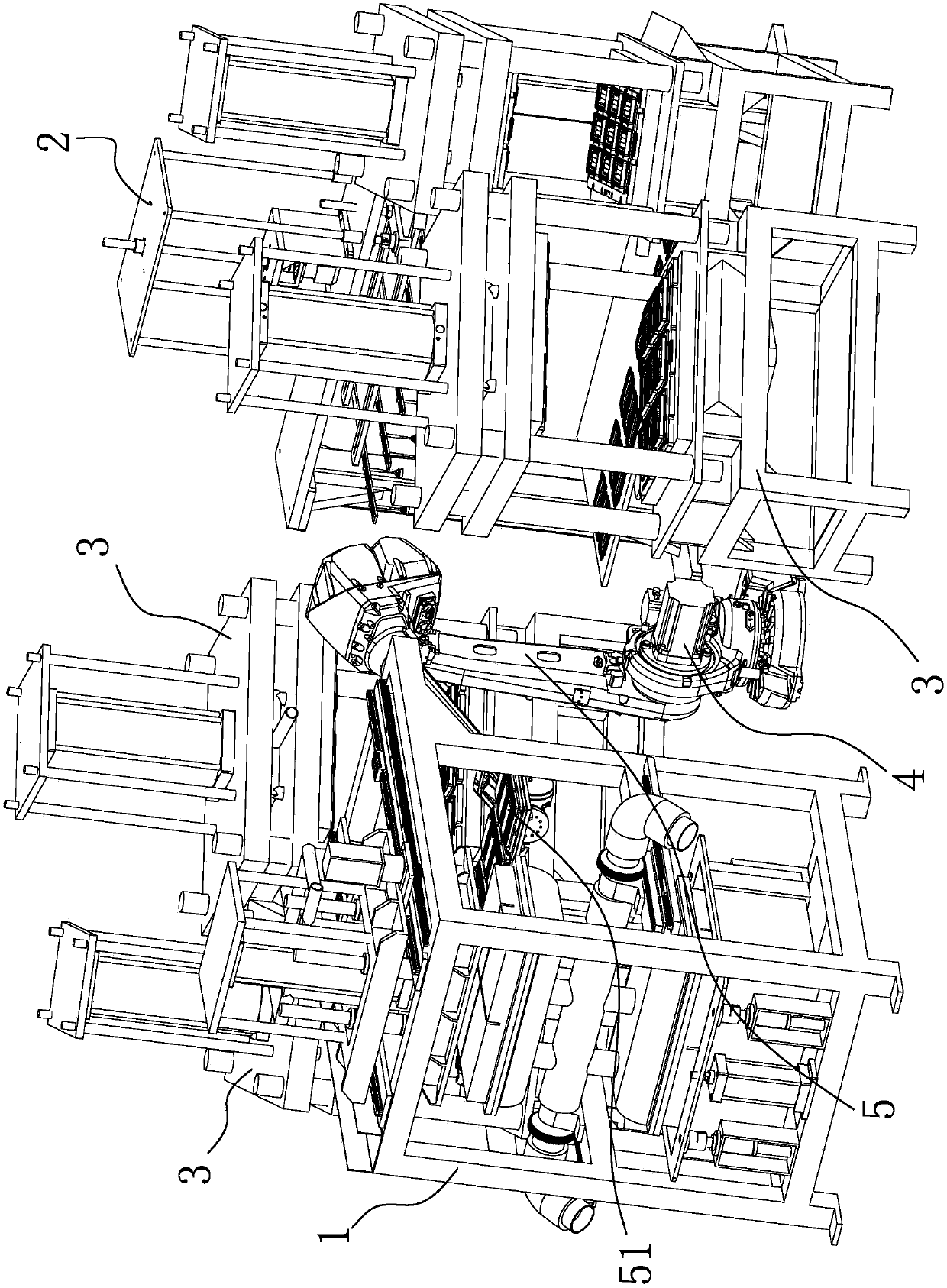

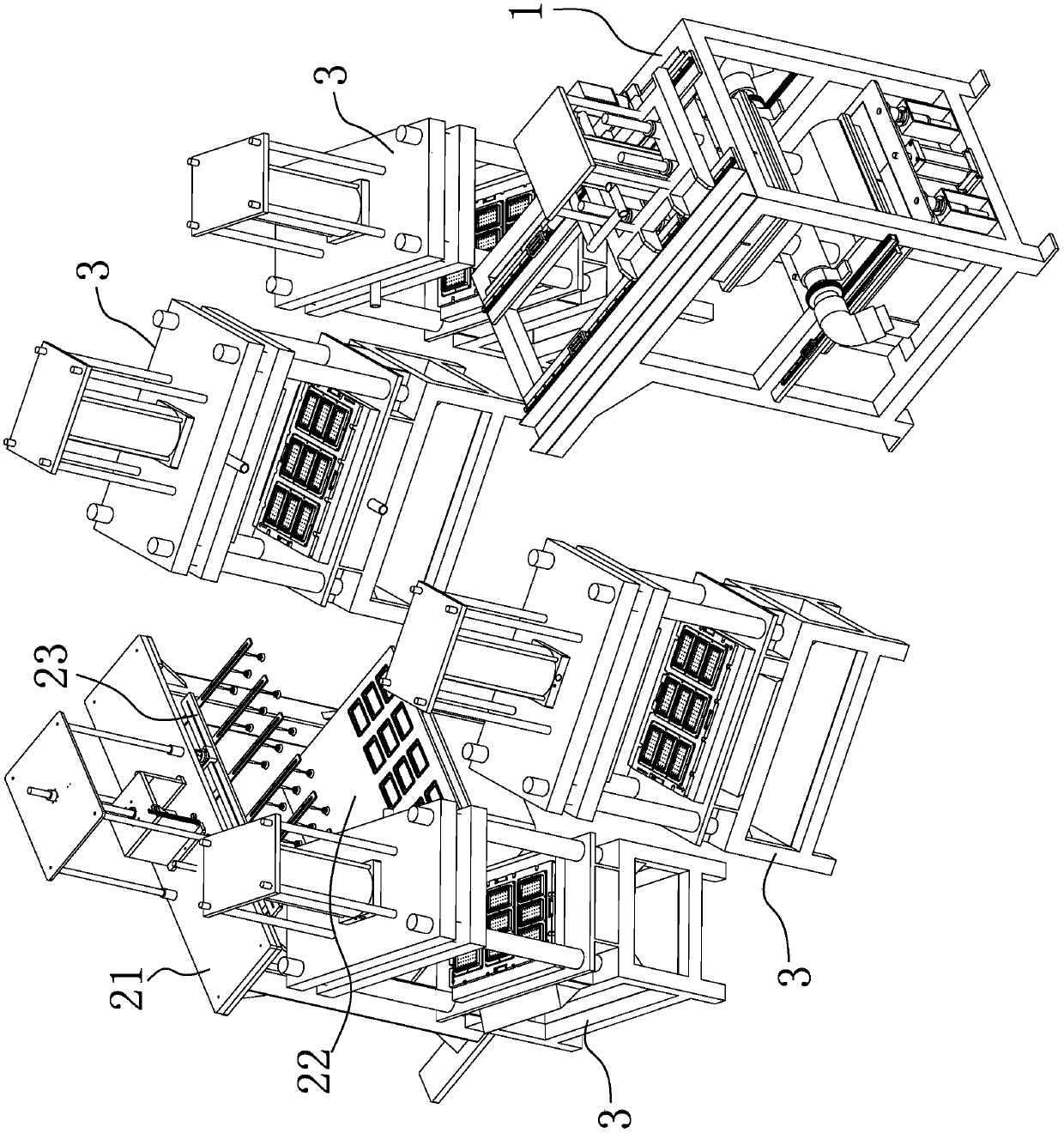

[0047] Such as Figure 1-3 As shown, this flexible production line for producing pulp molded products includes at least one product forming equipment 1, at least one product palletizing equipment 2 and several hot pressing and shaping equipment 3, the product forming equipment 1 of the present embodiment, the thermal Pressing and shaping equipment 3 and product stacking equipment 2 encircle and form a circle.

[0048]This production line also comprises at least one transfer device 4, is connected with a mechanical arm 5 on each transfer device 4, as Figure 4-5 As shown, at least one suction cup 51 is connected to the mechanical arm 5, and the transfer device 4 is located in the central area of the circle forming a circle.

[0049] Through the above distribution design, it can not only effectively improve production efficiency, but also further reduce labor intensity. At the same time, even if multiple suction cups are set on the same mechanical arm, the space occupied by i...

Embodiment 2

[0084] Such as Figure 11 As shown, the structure and principle of this embodiment are basically the same as those of Embodiment 1, and will not be repeated here. The difference lies in that the hot-press setting equipment 3 and the product palletizing equipment 2 are respectively distributed on a straight line.

Embodiment 3

[0086] Such as Figure 8-9 As shown, the structure and principle of this embodiment are basically the same as those of Embodiment 1, so we won’t repeat them here. The difference lies in:

[0087] When the number of suction cups is more than one, due to the limitation of vertical and lateral spaces, the thermocompression setting upper mold 33 is connected with the horizontal driving mechanism 35 . The horizontal driving mechanism 35 includes a horizontal guiding mechanism connected between the upper die 33 for thermoforming and the equipment frame 31, and the horizontal guiding mechanism includes a guiding structure of a guide rail and a slide block, or a guiding structure of a screw mandrel and a screw sleeve.

[0088] A horizontal driver 36 connected to the hot pressing upper mold 33 is provided on the equipment frame 31, and the horizontal driver is an air cylinder or an oil cylinder or an electric push rod.

[0089] Through the action of the horizontal driver 36, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com