Magnetostriction type double-stage displacement regulating mechanism for multiple spliced mirror surfaces

A magnetostrictive, displacement adjustment technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

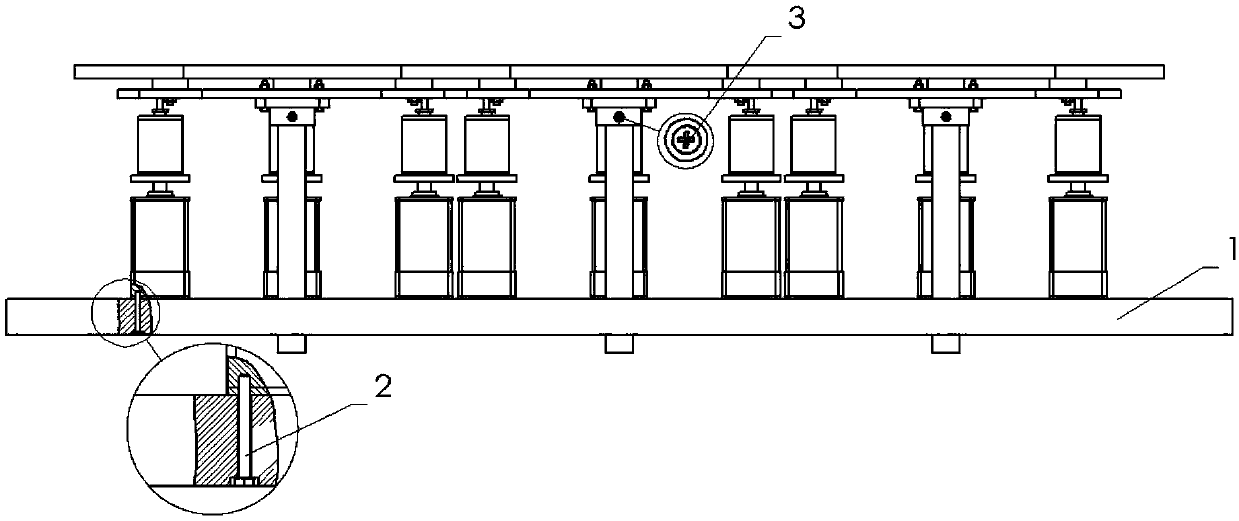

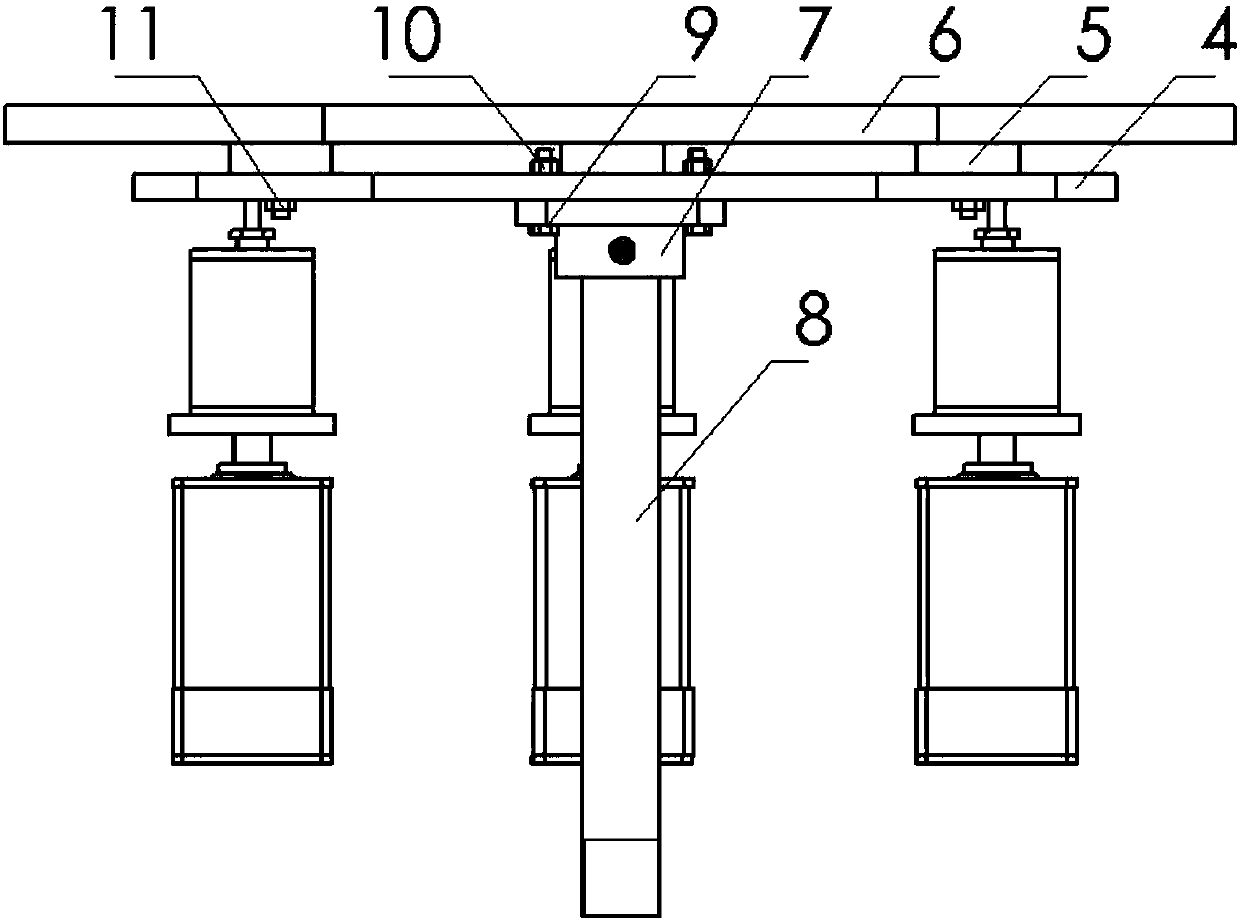

Embodiment 1

[0047] As shown in Figure 1, when working, the electric cylinder 12 is energized, and the giant magnetostrictive actuator 14 performs a fast linear motion under the drive of the electric cylinder 12. When reaching a suitable position, the electric cylinder 12 is powered off and stops working; When the giant magnetostrictive actuator 14 works, an alternating current is passed into the drive coil 21, and the current generates an alternating magnetic field inside the drive coil 21, and the giant magnetostrictive rod 22 moves along the axial direction under the action of the alternating magnetic field. Generate magnetostrictive deformation, and then push the output shaft 25 in the giant magnetostrictive actuator 14 to produce axial displacement; the lower surface of the reflector 6 is connected with the upper surface of the flexible rubber block 5 by gluing, and the upper end of the flexible rubber block 5 The external thread of part b and the through hole at the edge of the elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com