Double-cable winch device for ultrasonic hole and groove formation quality inspection

An ultrasonic and double-cable technology, which is applied in the test of basic structure, survey of on-site foundation soil, construction, etc., can solve the problems that the detection accuracy of the inclination angle cannot be guaranteed, the twisting of the ultrasonic sensor is blocked, and it is difficult to guarantee, and the weight is light. , simplify the structure, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

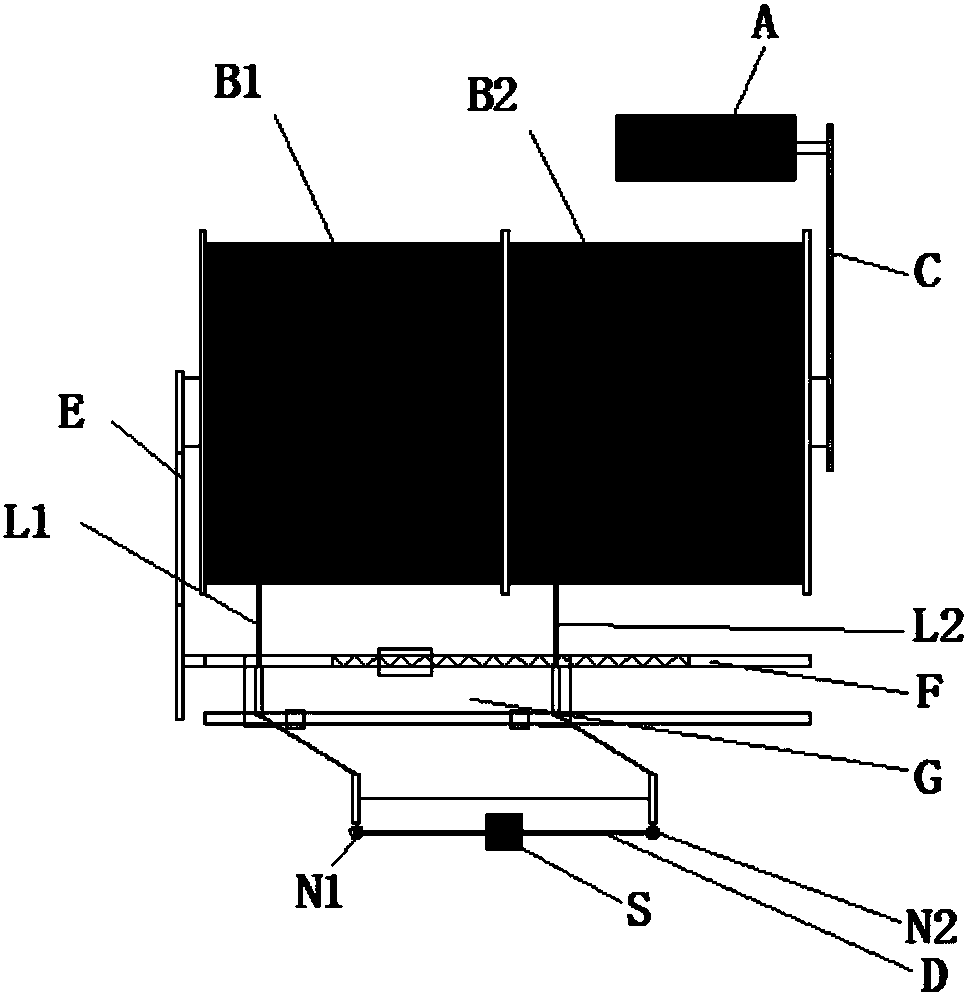

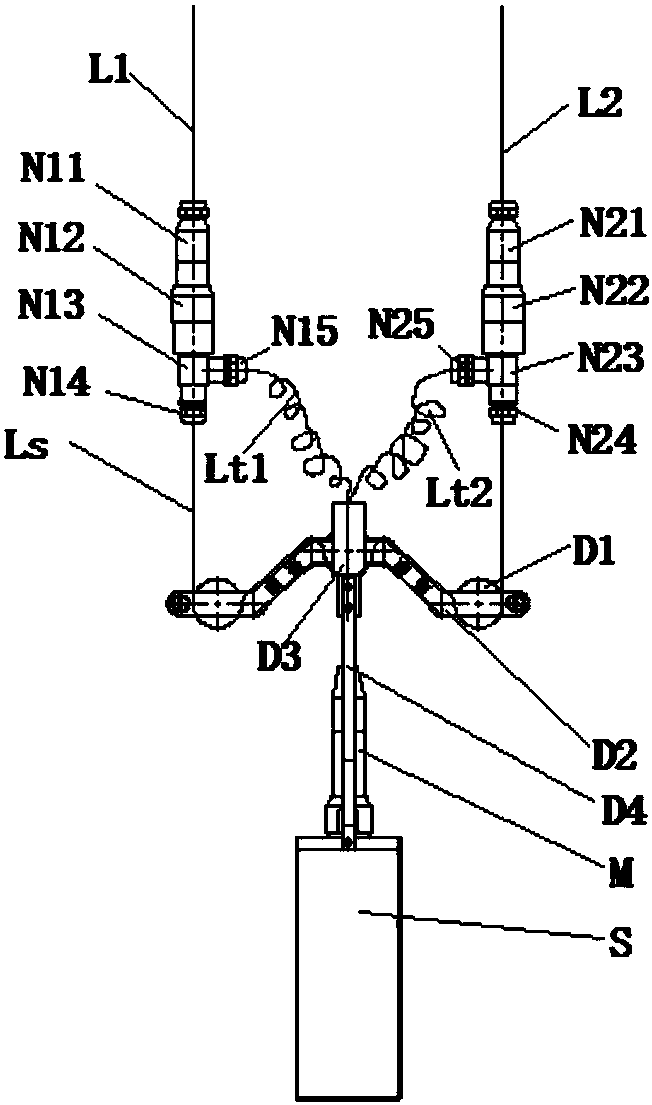

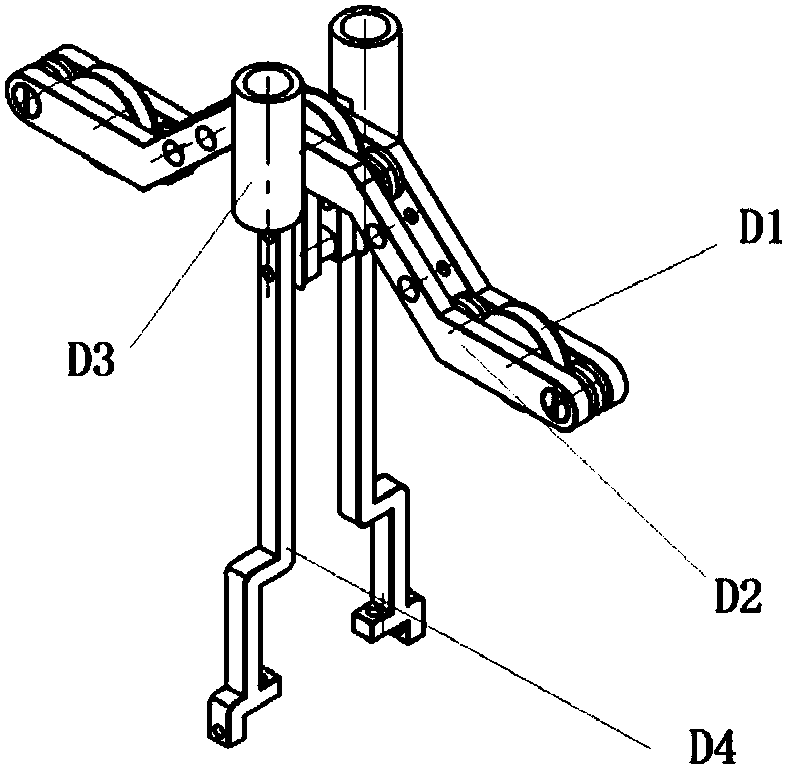

[0031] Such as Figure 1~4As shown, a double-cable winch device for ultrasonic hole-forming and grooving quality inspection includes an ultrasonic sensor S and a balance frame D2. Several pulleys D1 are arranged along the balance frame D2, and the middle of the balance frame D2 is provided with a mounting Bracket D4, the installation bracket D4 is connected with the ultrasonic sensor S, one end of the positioning wire rope Ls is connected with the bottom end interface of the left adapter N1, and the other end bypasses each pulley D1 on the balance frame D2 in S shape and then connects with the right adapter The bottom interface of N2 is connected, the top interface of the left adapter N1 is connected with the bottom end of the left cable L1, and the top interface of the right adapter N2 is connected with the bottom end of the right cable L2. There are preferably three pulleys D1, which are respectively arranged at the middle and both ends of the balance frame D2.

[0032] Lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com