Guiding system for magnetic suspension conveying device made from refractory material

A technology for conveying devices and refractory materials, applied in conveyors, transportation and packaging, non-mechanical conveyors, etc., can solve problems such as low construction efficiency, difficult construction, and dangerous construction, and achieve convenient operation, shortened time and cost, The effect of smooth operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

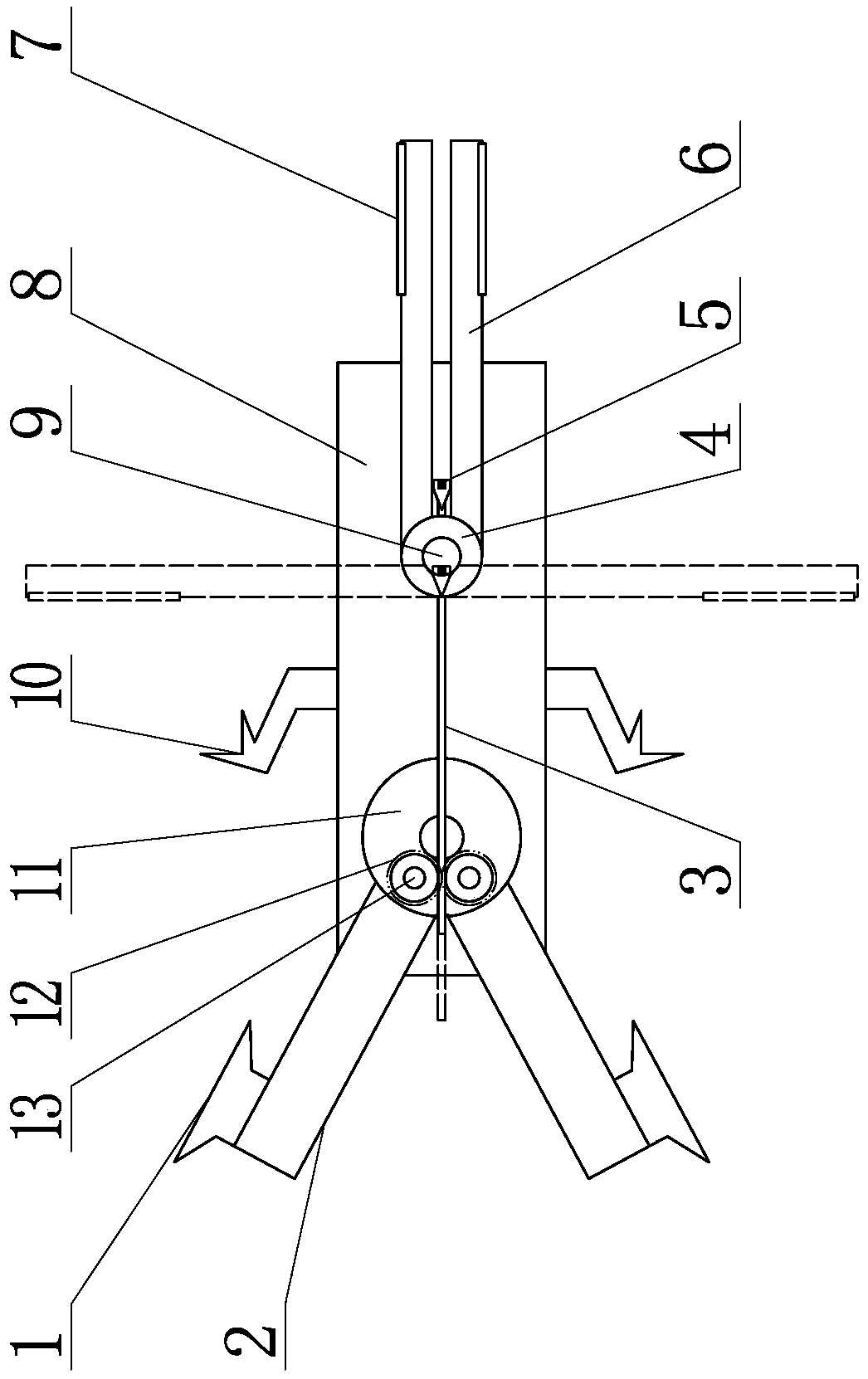

[0037] like figure 1 As shown, a guiding system of a refractory material magnetic suspension conveying device is composed of two parts: a socket holder and a magnetic suspension conveying device. The first is the suspension magnetic feeding device, which is suspended in the furnace body of the boiler through magnetic attraction, and can adjust the lateral angle during the process of rising and falling under the control of magnetic force. The second is the socket holder, which is fixed at the access and inspection port of the furnace, and is used to ensure that the suspension magnetic feeding device can enter and exit the furnace smoothly, and at the same time, the suspension magnetic feeding device is positioned, maintained and fixed.

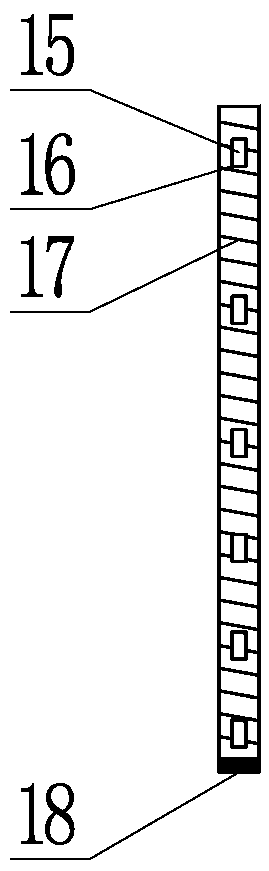

[0038] The socket fixator includes an insertion catheter, a lateral fixation device, a medial fixa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com