Gridiron lifting mechanism used for oven

A lifting mechanism and grill technology, applied in the field of ovens, can solve the problems of poor control of heat, inability to observe the color of bread slices in the oven, and inability to perform memory checks, etc., to achieve convenient control, small space occupation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

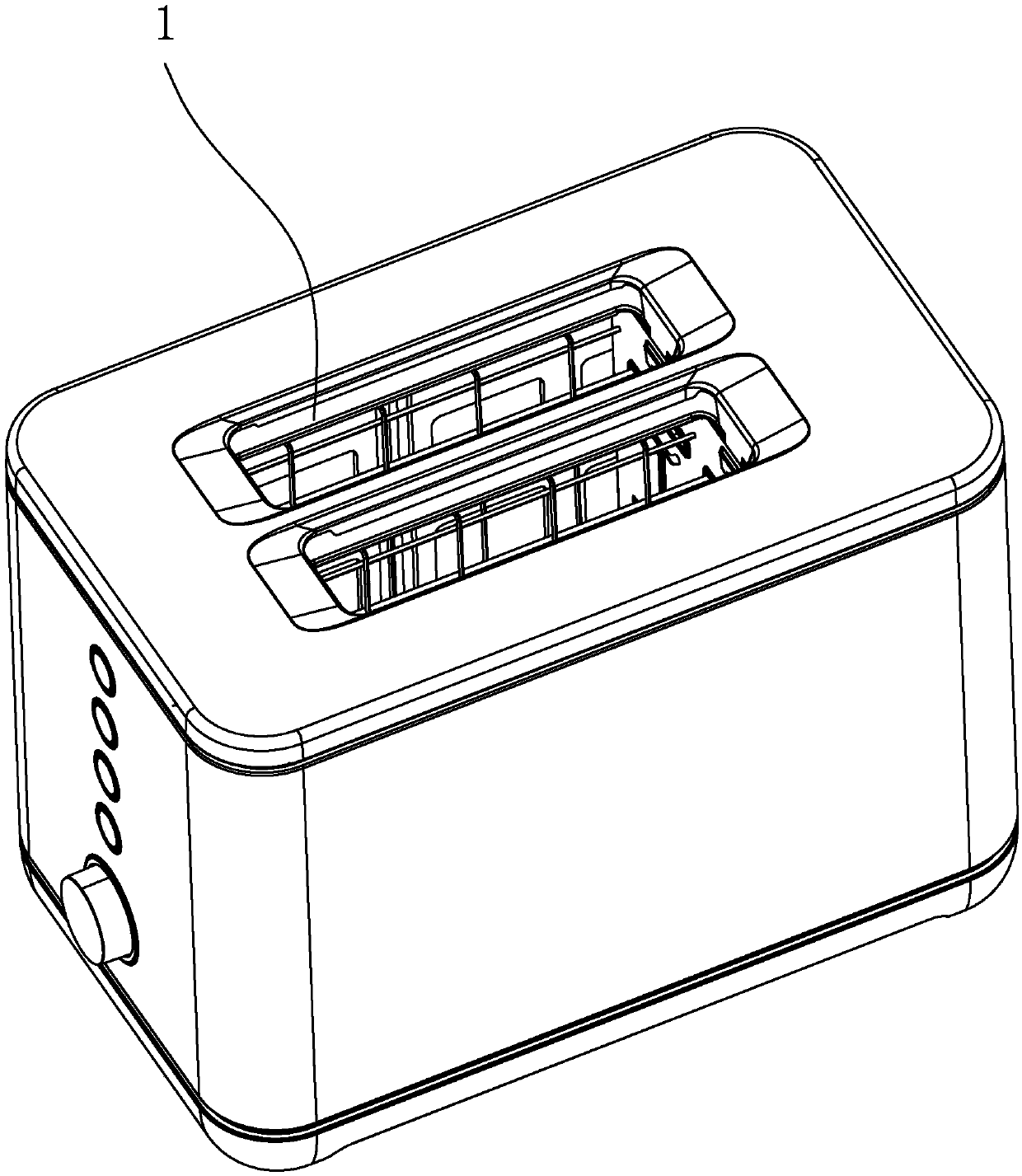

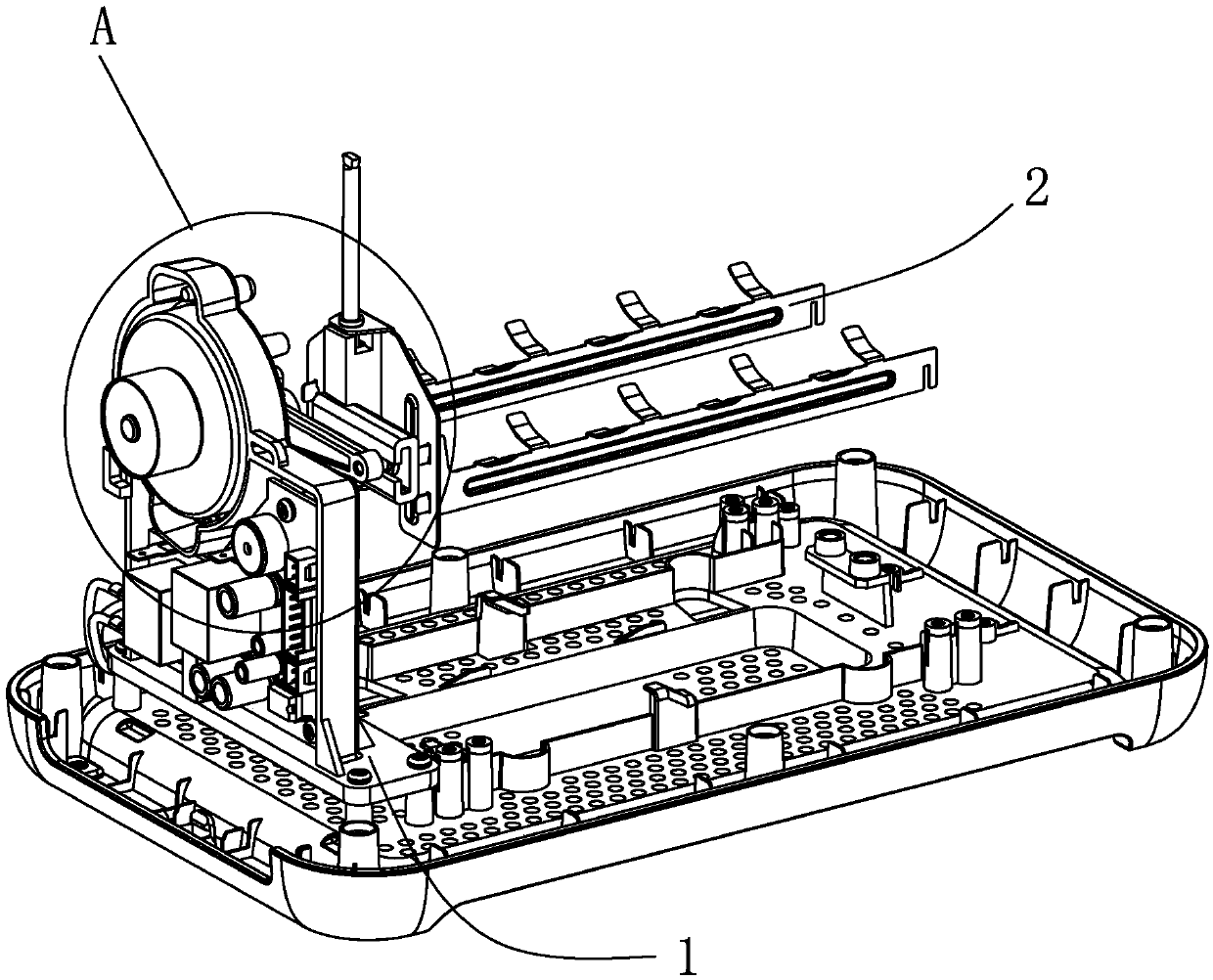

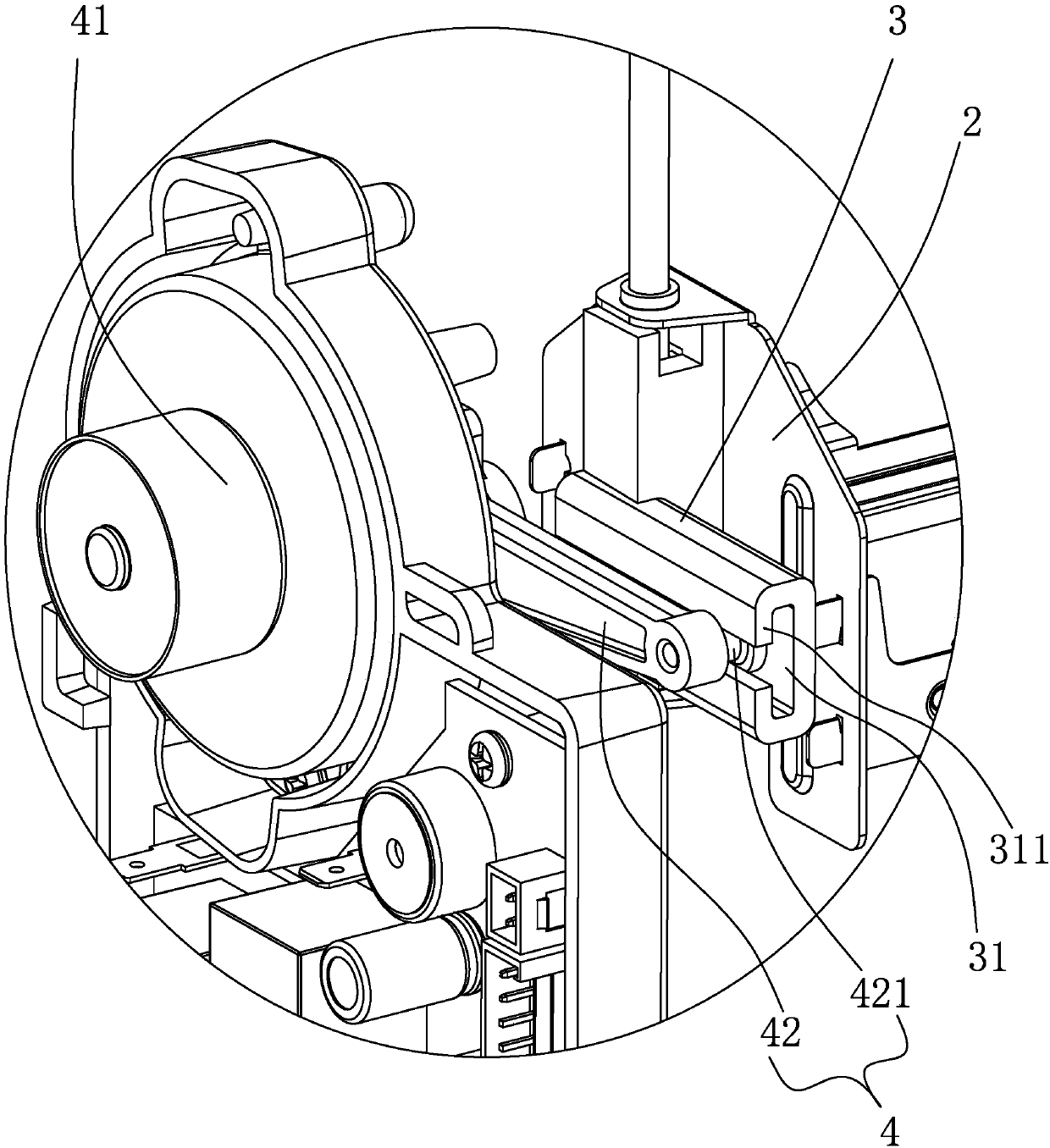

[0029] Such as Figure 1 to Figure 8 As shown, a grill elevating mechanism for an oven in this embodiment includes a frame 1 arranged in the oven, and the frame 1 is provided with a grill 2 that can slide vertically. The end of the frame 2 is provided with a slider 3 that moves with the grill 2, and the slider 3 is provided with a chute 31 along the horizontal direction, and the frame 1 is also provided with a mechanism for driving the slider 3 to move up and down. The drive assembly 4, the drive assembly 4 includes a motor 41 arranged on the frame 1, the output shaft of the motor 41 is provided with a swing arm 42, and the end of the swing arm 42 is provided with a Sliding connecting shaft 421 . The present invention adopts the drive assembly 4 to electrically control the lifting of the grill 2, which can realize the automatic and slow lifting of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com