Water blowing structure for coal mine underground gas extraction and construction method thereof

A technology for gas drainage and coal mines, which is applied in the direction of gas discharge, drainage, mining equipment, etc., can solve the problems that affect the gas drainage time, gas drainage effect, easy water accumulation, etc., achieve significant technological progress, improve drainage concentration, Solve the effect of coal and gas outburst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

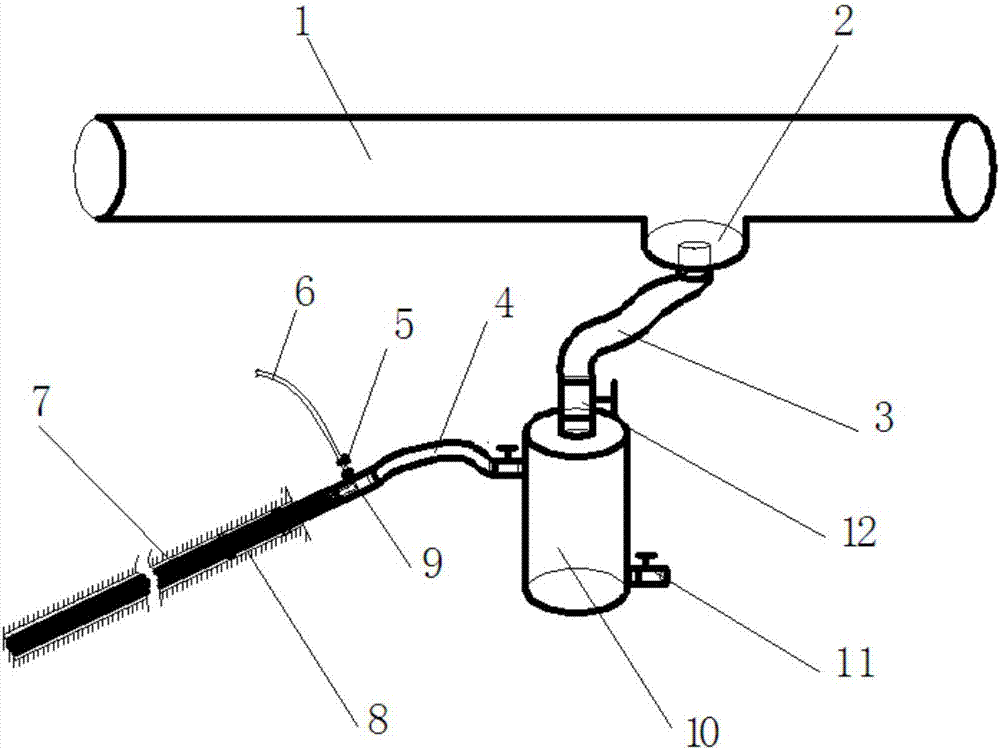

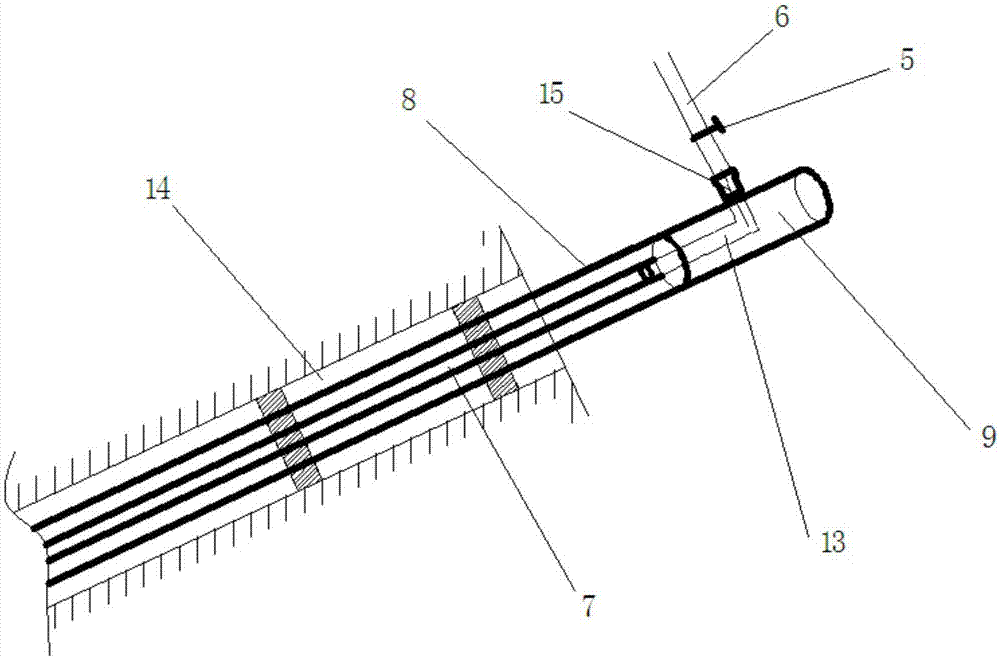

[0017] Embodiment 1: as attached figure 1 , 2 As shown, a coal mine underground gas drainage blowing structure, which includes a drainage system 6, a gas-water separator 10, a water discharge device 11 and a compressed air system 6, the upper part of the gas-water separator 10 is provided with a suction port, the suction There is a valve one 12 on the air port, the valve one 12 is connected with the tee 2 of the pumping system 1 through the hose one 3, the bottom of the gas-water separator 10 is connected with a water discharge device 11, and the upper part of the gas-water separator 10 The side is connected with a hose 2 4, and the hose 2 4 is connected with a water blower 9, and the side of the water blower 9 is connected with the compressed air system 6 through the valve 2 5, and the other end of the water blower 9 is connected to the sealing hole. The screen pipe 8 is connected, and the inside of the sealing screen pipe 8 is provided with a water blowing pipe 7, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com