Double-function small template sewing machine

A sewing machine, dual-function technology, applied in sewing machine components, sewing machine control devices, sewing equipment, etc., can solve the problems of large volume and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

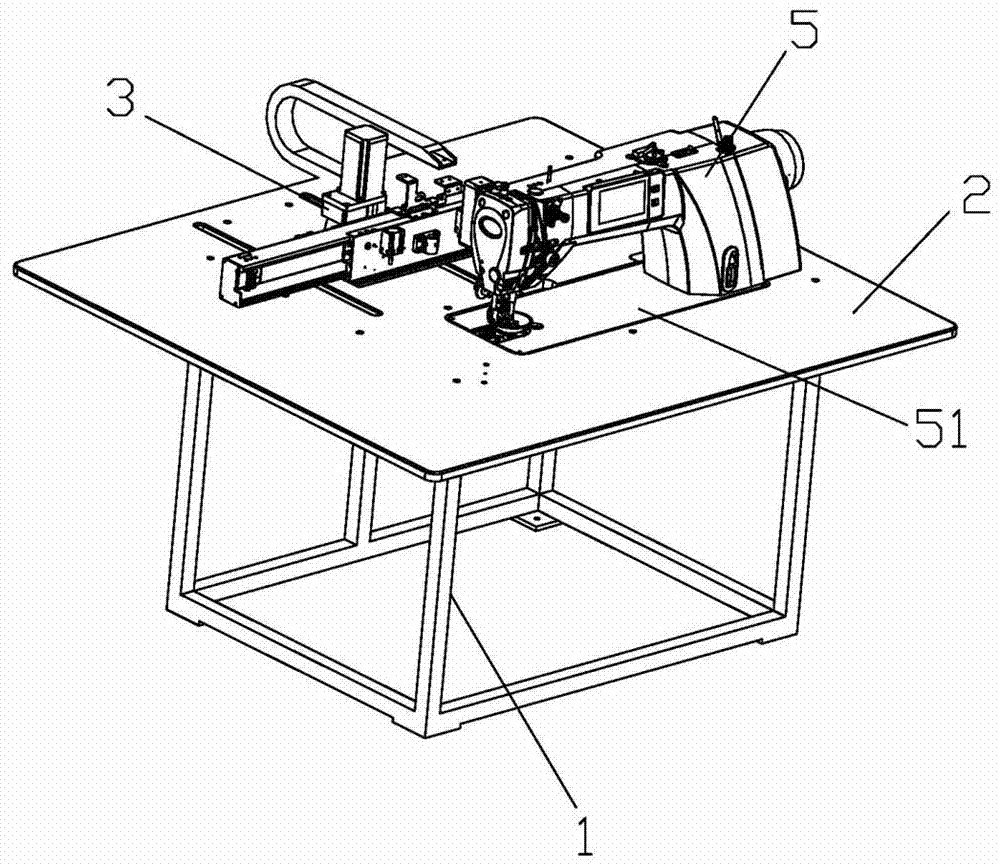

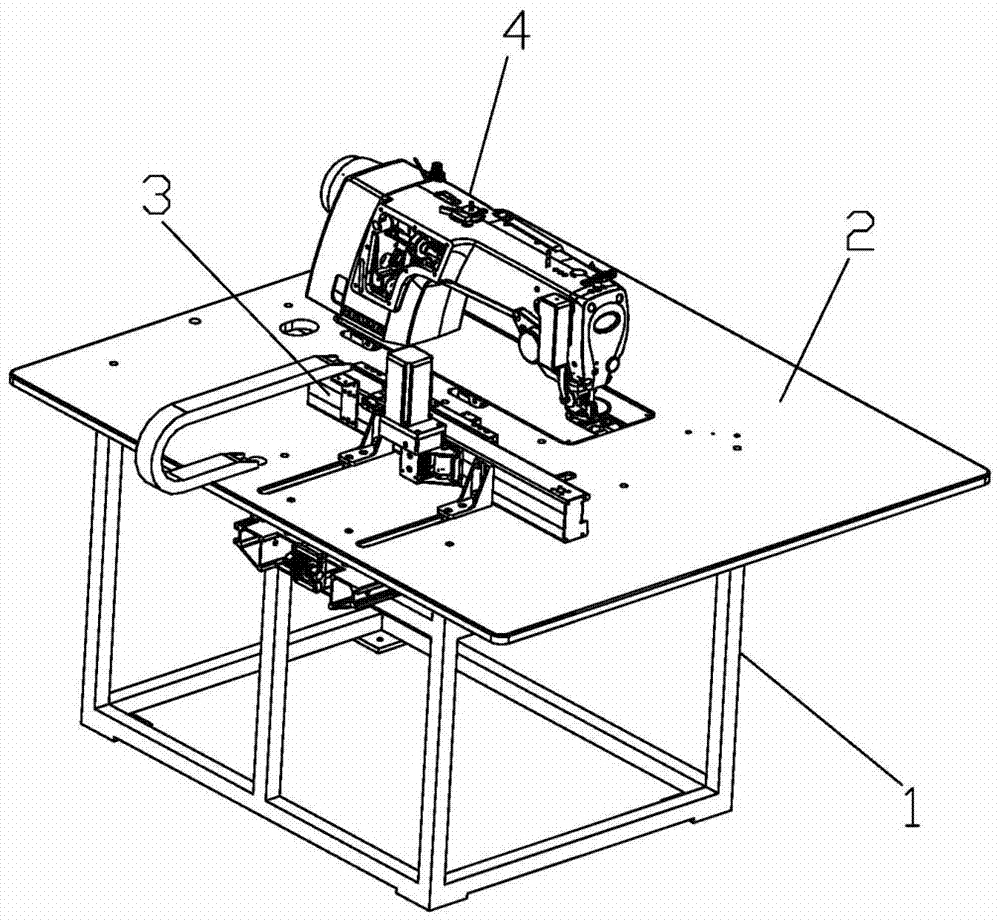

[0036] Such as Figure 1-17 As shown, a dual-function small template sewing machine includes a frame 1, a worktable 2, a template driving mechanism 3 and a sewing machine head 5, and is characterized in that: the position on the front side of the worktable 2 is on the right side The machine head installation opening 21 is set on the upper opening, the sewing head 5 is installed at the head installation opening 21, and the template driving mechanism 3 is arranged on the position where the worktable is located at the left side of the sewing head 5 rear side.

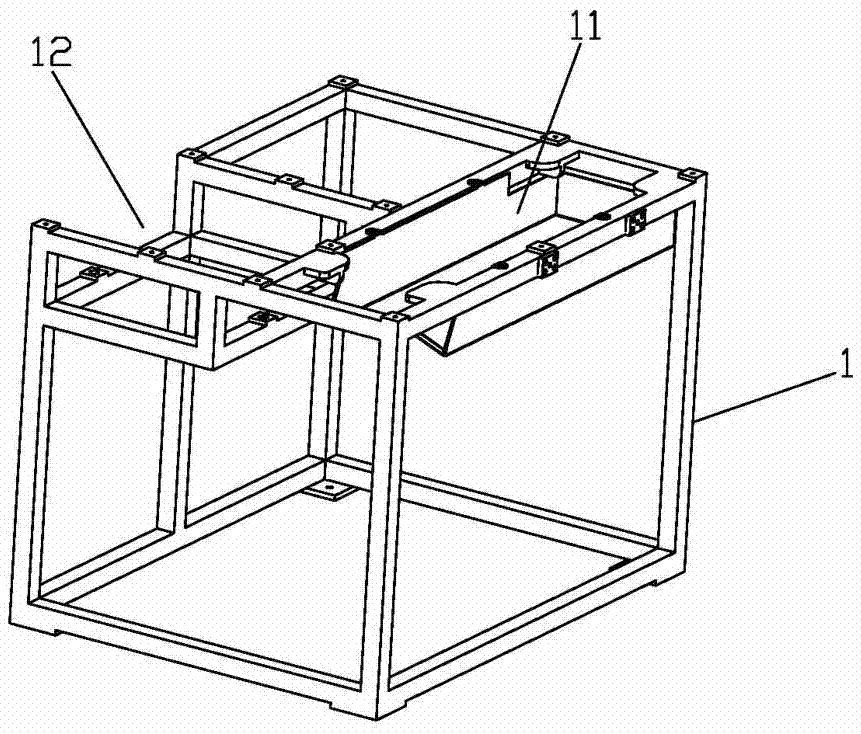

[0037] The top of the frame 1 is provided with an oil pan 11 at the position corresponding to the head installation opening 21 of the workbench 2, the sewing head 5 is hinged at the head installation opening 21 of the workbench 1, and the sewing head 5 The worktable 41 is flush with the worktable 2, and the part below the worktable is accommodated in the oil pan 11.

[0038] The distance from the front edge of the worktab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com