An Air Chamber Structure for Reducing Vacuum Absorbing Negative Pressure Fluctuation of Rotor Spinning Machine

A rotor spinning machine and air chamber technology, which is applied to spinning machines, open-end spinning machines, continuous winding spinning machines, etc., can solve the problem that the yarn quality is greatly affected and the space available for the miscellaneous box Small size, high frequency of manual removal of impurities, etc., to achieve the effect of simple and reliable structure, prolonging coverage time and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

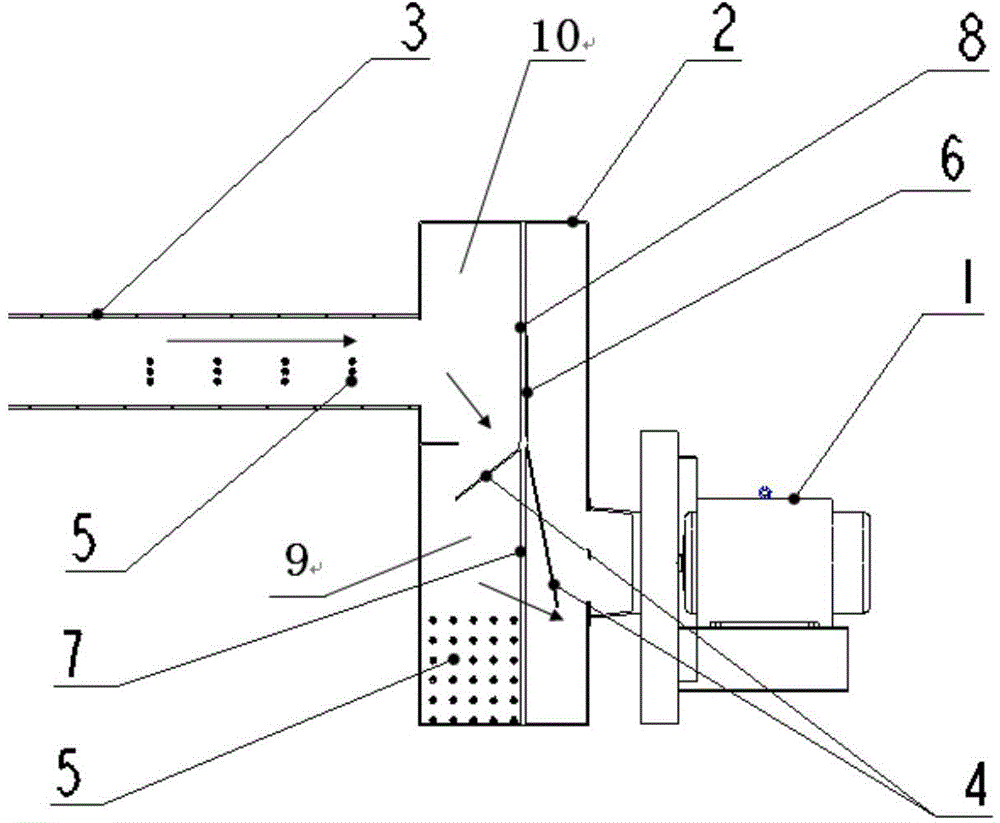

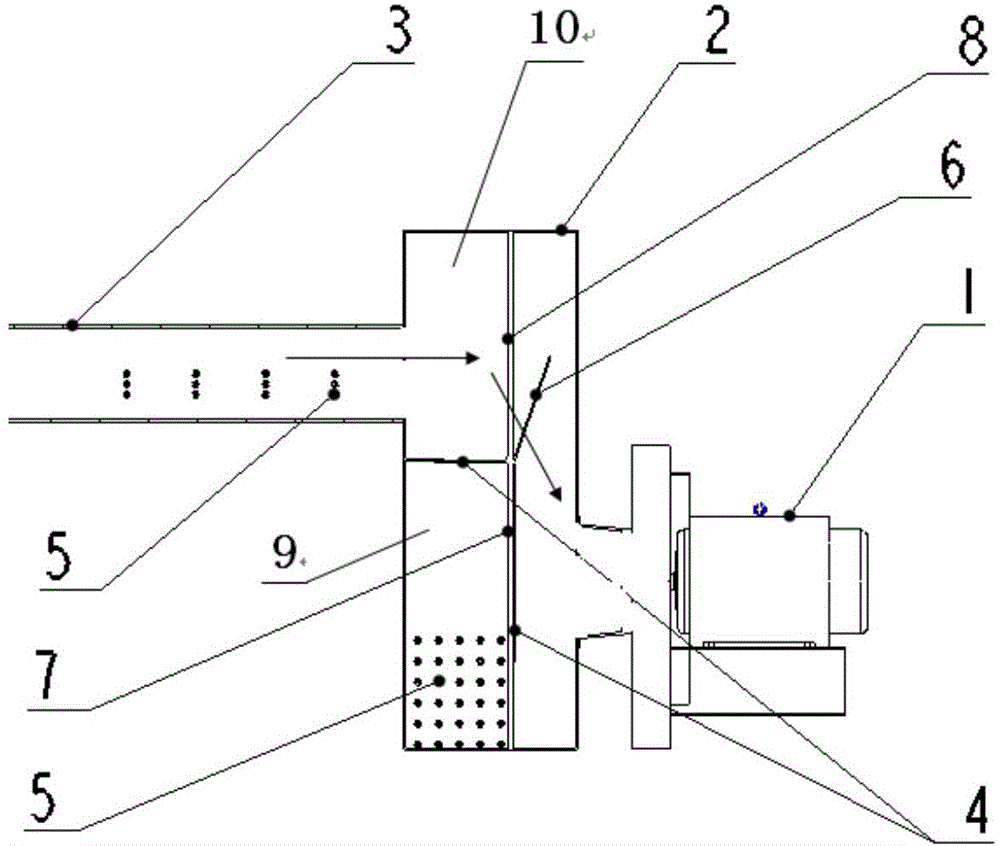

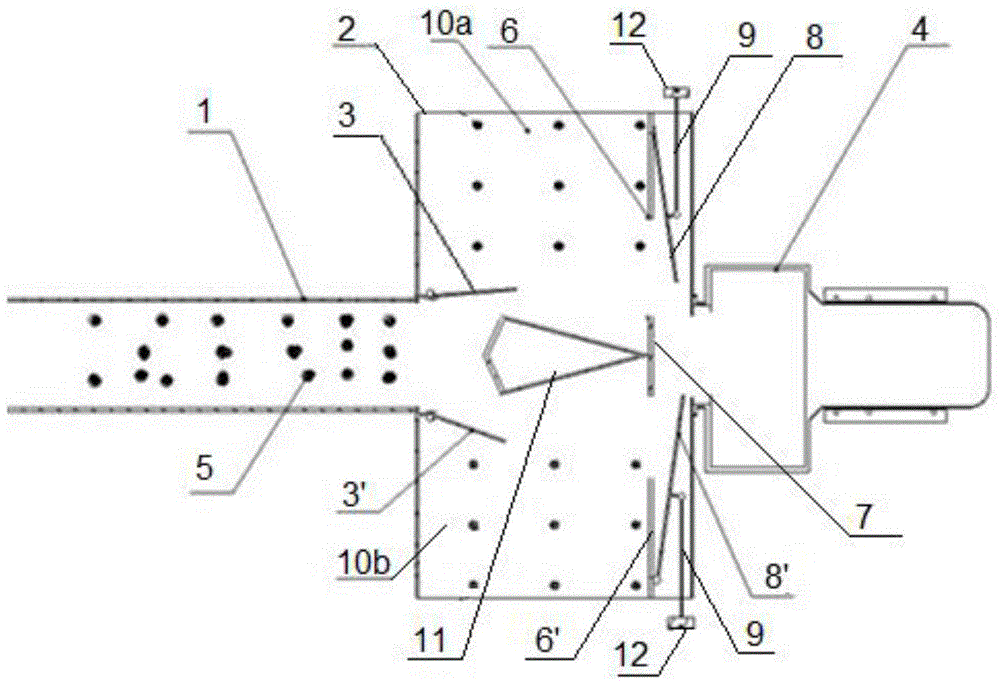

[0037] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail:

[0038] combine image 3 As shown, an air chamber structure for reducing the fluctuation of the miscellaneous suction negative pressure of a rotor spinning machine includes an air chamber 2, the front end of the air chamber communicates with the miscellaneous suction duct 1, and the rear end of the air chamber communicates with the miscellaneous suction pipe 1. The fans are connected in 4 phases,

[0039] The air chamber is fixedly equipped with a left filter screen 6, a right filter screen 6' and a middle partition 7, and the left filter screen and the right filter screen are fixedly connected to the left and right side walls of the air chamber respectively, and the middle part The clapboard is located between the left filter screen and the right filter screen, facing the miscellaneous air duct. The left, right filter screen and the middle partition di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com