Rapier clamp for weaving carbon fiber expanded flat yarns

A technology of carbon fiber and flat yarn, which is applied in the field of weaving machinery parts, can solve the problems of poor clamping and low friction coefficient, and achieve the effects of increasing reliability, reducing damage, and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

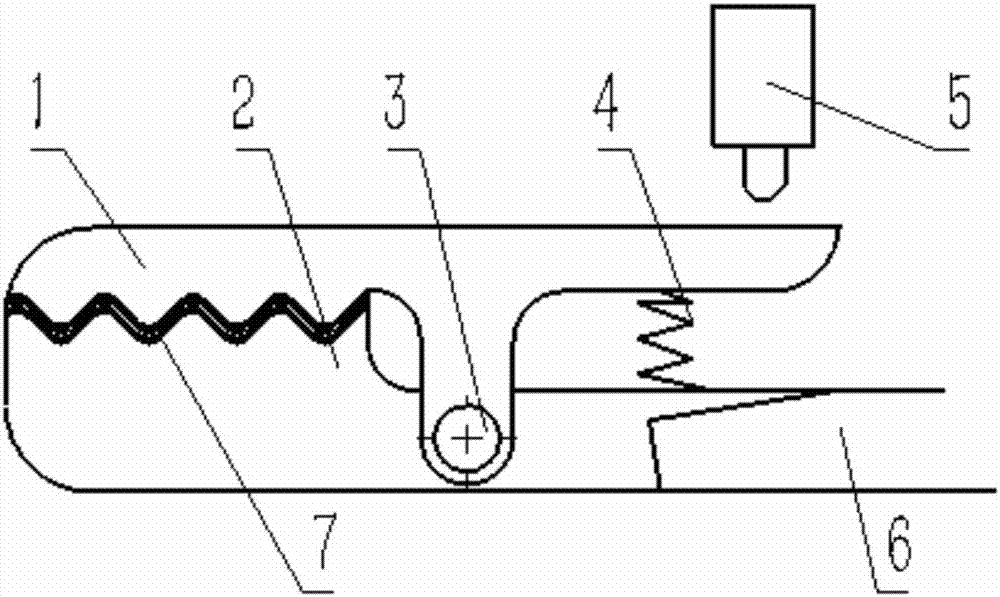

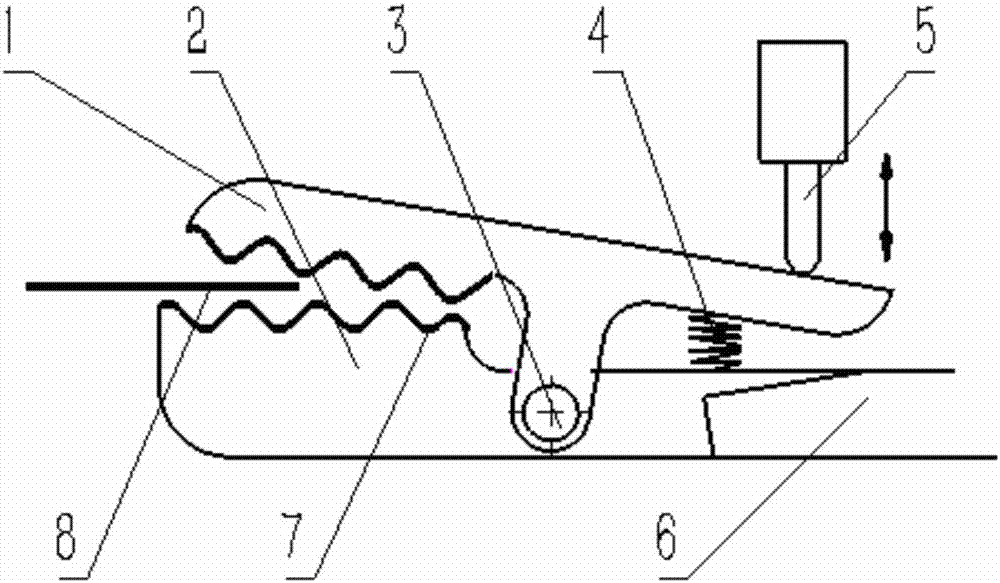

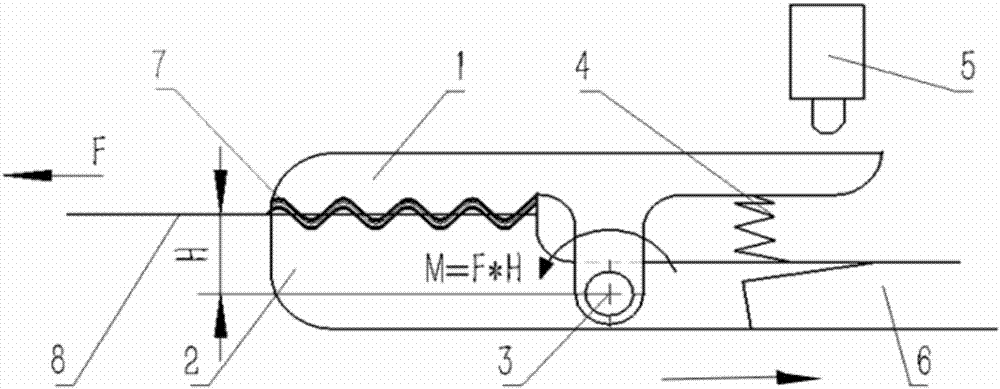

[0021] Such as Figure 1-3 As shown, a rapier chuck for carbon fiber expanded flat yarn weaving includes a movable upper jaw 1, a static lower jaw 2, a rotating shaft 3, a compression spring 4, a control device 5 and a weft yarn 8, wherein the movable upper jaw 1 and the static lower jaw 2 Hinged through the rotating shaft 3, and the movable upper jaw 1 can rotate around the rotating shaft 3, a compression spring 4 is provided between the tail end of the movable upper jaw 1 and the stationary lower jaw 2, and a control device is provided on the upper part of the tail end of the movable upper jaw 1 5. It is used to drive the movable upper jaw 1 to rotate, open the movable upper jaw 1, and introduce the weft yarn 8.

[0022] The static lower jaw 2 is installed on the front end of the rapier 6. When the movable upper jaw 1 and the static lower jaw 2 clamp the weft yarn 8, the distance between the horizontal plane of the clamping center and the center of the rotating shaft in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com