Hydrogen producing system

A hydrogen production system and hydrogen technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of inability to scale and industrialize hydrogen production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

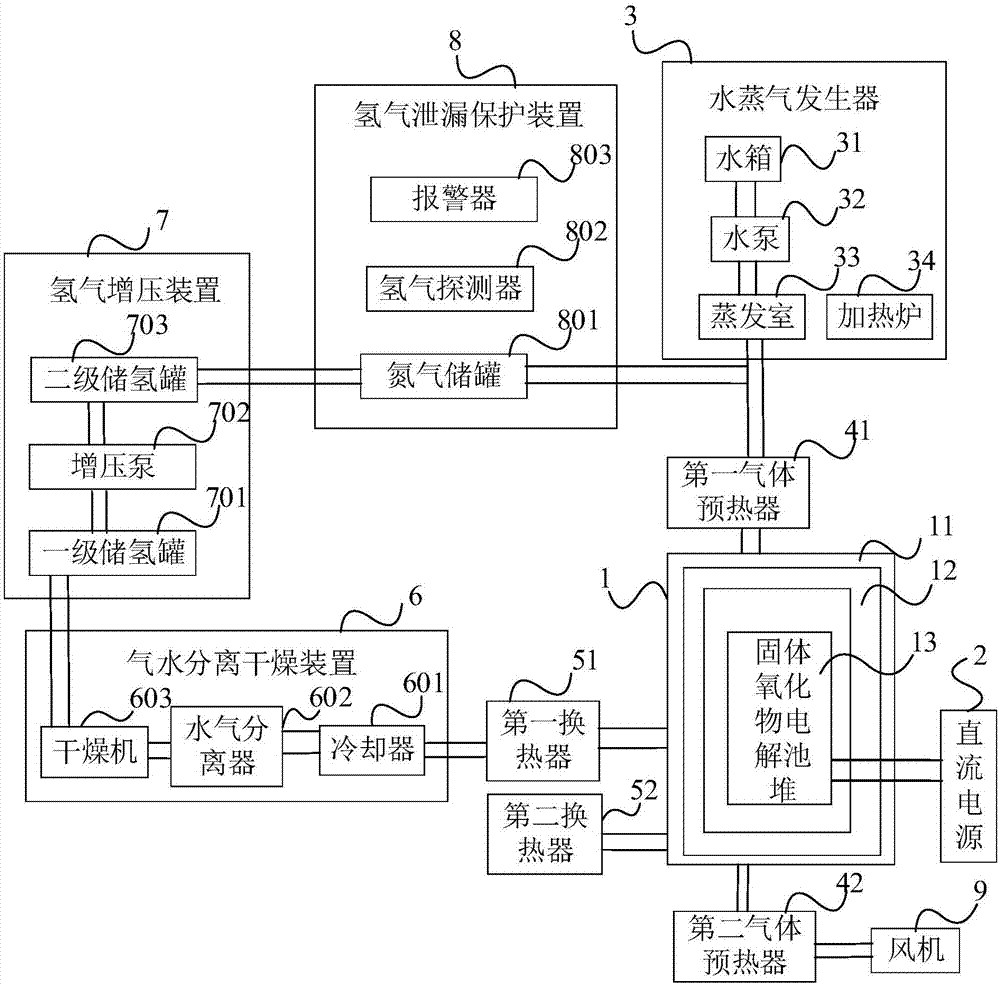

[0028] Such as figure 1 As shown, a hydrogen production system includes a hot box 1, a DC power supply 2, a steam generator 3, a first gas preheater 41, a second gas preheater 42, a first heat exchanger 51, and a second heat exchanger Heater 52, gas-water separation and drying device 6, hydrogen pressurization device 7, hydrogen leakage protection device 8 and fan 9.

[0029] The hot box 1 includes a shell 11, an insulating layer 12 and a solid oxide electrolytic cell stack 13, the insulating layer 12 is arranged on the inner wall of the shell 11, and the solid oxide electrolytic cell 13 is located at the structure formed by the insulating layer 12. in the closed cavity. The shell 11 is a steel plate with a thickness of 1mm-20mm, the thickness of the insulation layer 12 is 1mm-20mm, and the material of the insulation layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com