Loading machine

A technology of loader and installation department, which is applied in the direction of lifting device, lifting frame, etc., which can solve the problems of installation and maintenance influence, the failure of lifting mechanism to lift, and the increase of the cost of the lift, so as to facilitate installation and maintenance, avoid safety hazards, and pass smoothly sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

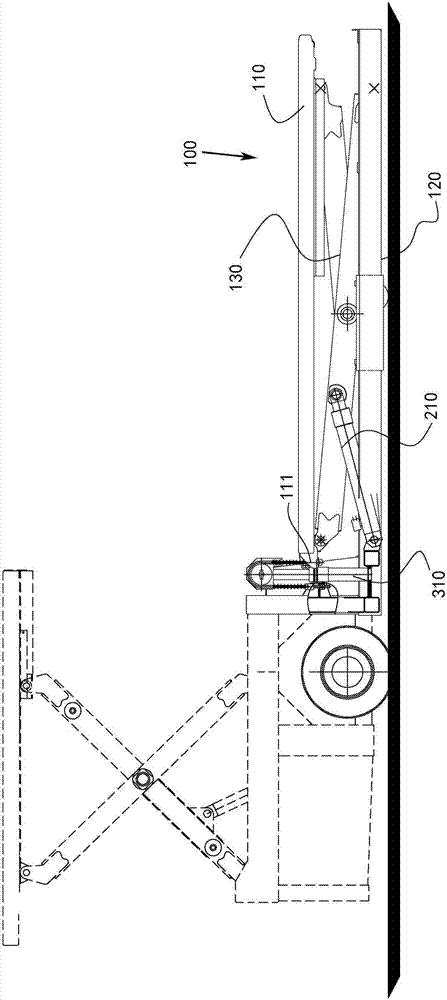

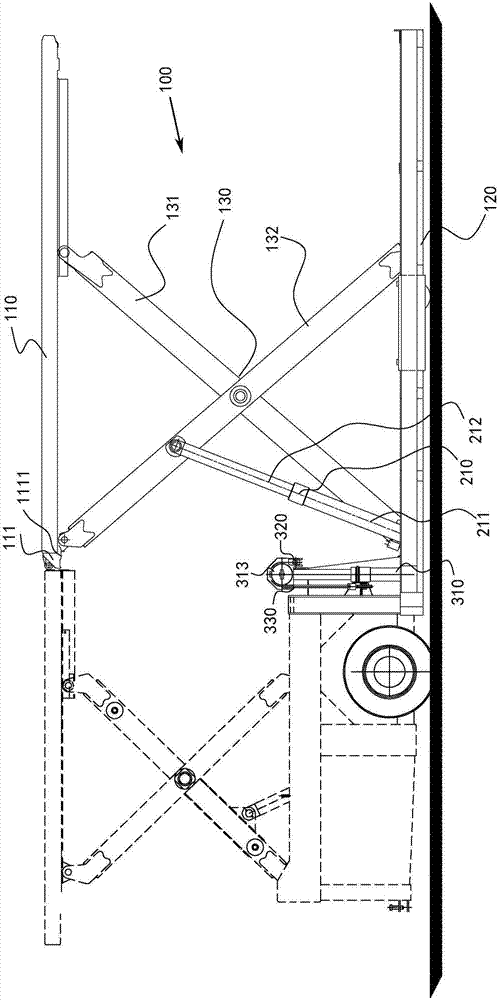

[0030] Refer to figure 1 , figure 1 Representatively shows a schematic structural diagram of a loader that can embody the principles of the present invention when it is in a working state, and specifically shows that the main platform 110 of the loader is in an unlifted working state. In this exemplary embodiment, the loader proposed in the present invention is an example of a cargo loader, and further, a cargo loader capable of transporting ultra-wide cargo is taken as an example for description. It is easy for those skilled in the art to understand that in order to apply the loader proposed by the present invention to other fields, various modifications, additions, substitutions, deletions or other changes are made to the following specific embodiments, and these changes are still It is within the scope of the principle of the loader proposed by the present invention.

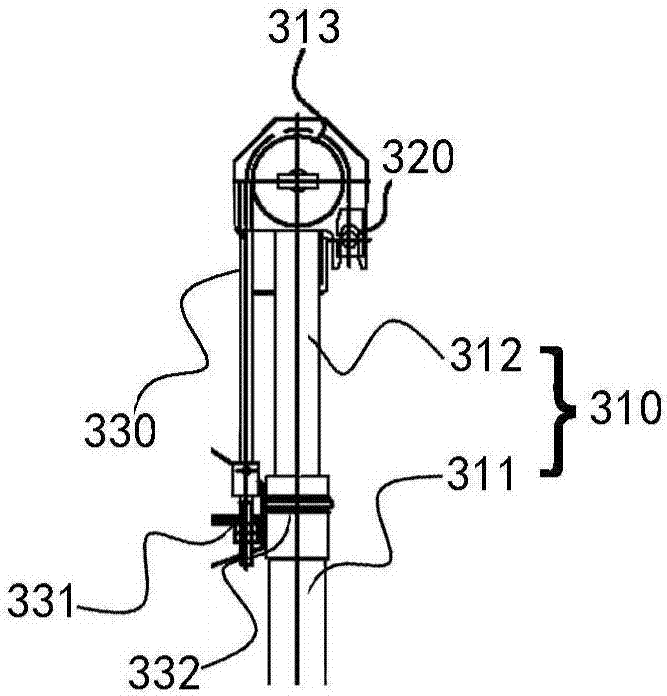

[0031] Such as figure 1 As shown, in this embodiment, the loader proposed by the present invention mainly inc...

Embodiment approach 2

[0044] Refer to Figure 5 , Figure 5 Representatively shows another exemplary embodiment of a loader that can embody the principle of the present invention, and specifically represents that the main platform 110 of the loader is in an unlifted working state. In this exemplary embodiment, the main structures and control principles of the loader proposed by the present invention are substantially the same as those of the first embodiment. The differences between this embodiment and the first embodiment will be described in detail below in conjunction with the drawings.

[0045] In this embodiment, the auxiliary lifting device is a third oil cylinder, and the mounting part and the lifting part of the auxiliary lifting device are the third cylinder 410 and the third telescopic rod of the third oil cylinder, respectively. The bottom of the third cylinder 410 is fixed to the base 120, and the third telescopic rod is telescopically arranged in the third cylinder 410 (and can be extende...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com