Mailbox producing and processing equipment

A processing equipment, letter box technology, applied in printing, stamping and other directions, can solve the problems of single function, high manufacturing cost, low marking efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

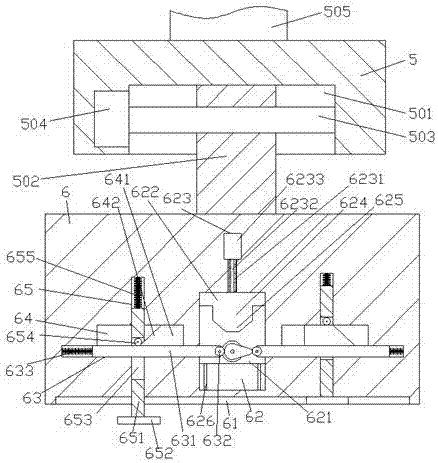

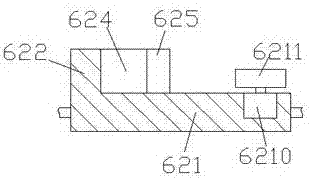

[0013] Such as figure 1 , figure 2 with image 3 As shown, a letter box production and processing equipment of the present invention includes a suspension platform 5 and a processing main frame 6 installed on the lower side of the suspension platform 5 in left and right translation, and a boom 505 is installed directly above the top of the suspension platform 5. The suspension platform 5 is provided with a positioning slot 501 with the mouth facing downward, and a connecting arm 502 extending downward is installed in the positioning slot 501 in translation, and the screw in the connecting arm 502 is equipped with left and right expansion screw shaft 503, the right end of the screw shaft 503 is rotated and connected with the right end wall of the adjustment groove 501, the left end of the screw shaft 503 is installed in cooperation with the main motor 504, and the outer surface of the main motor 504 Installed in the left end wall of the positioning groove 501 and fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com