Concrete prewetting tank truck

A concrete and pre-wetting technology, which is applied to clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve the problems of slow pre-wetting speed, poor pumpability, and low efficiency of light aggregates, and achieve high pre-wetting efficiency , Fast pre-wetting speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

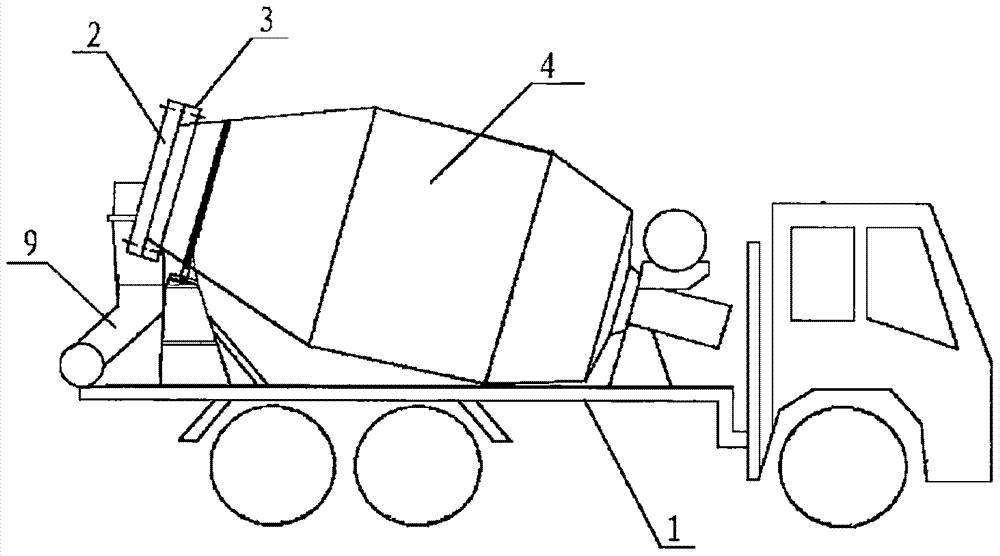

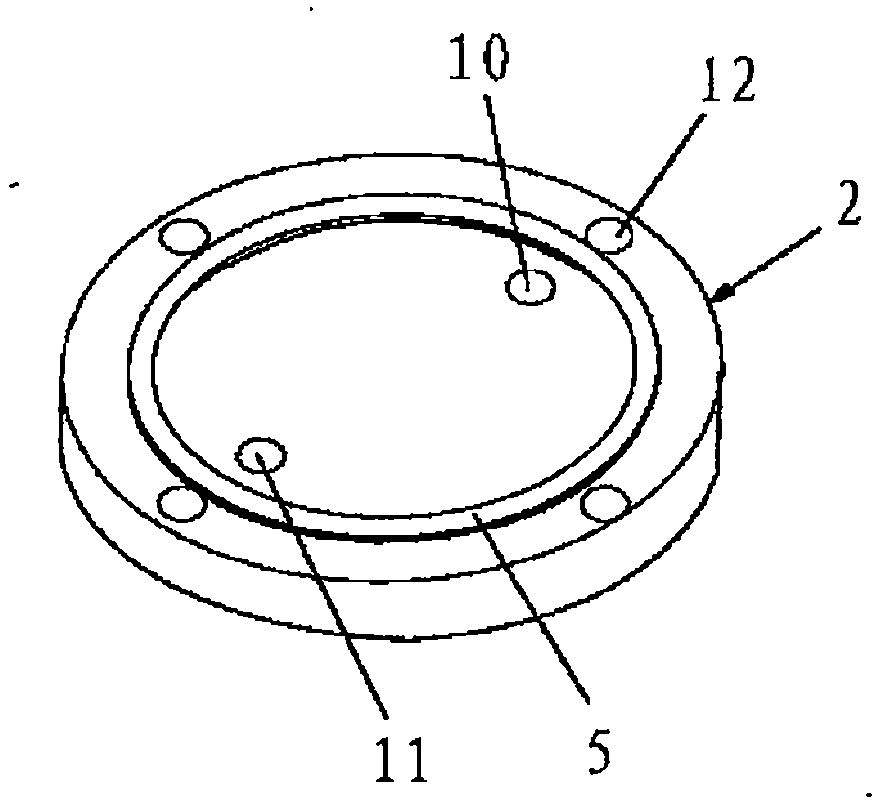

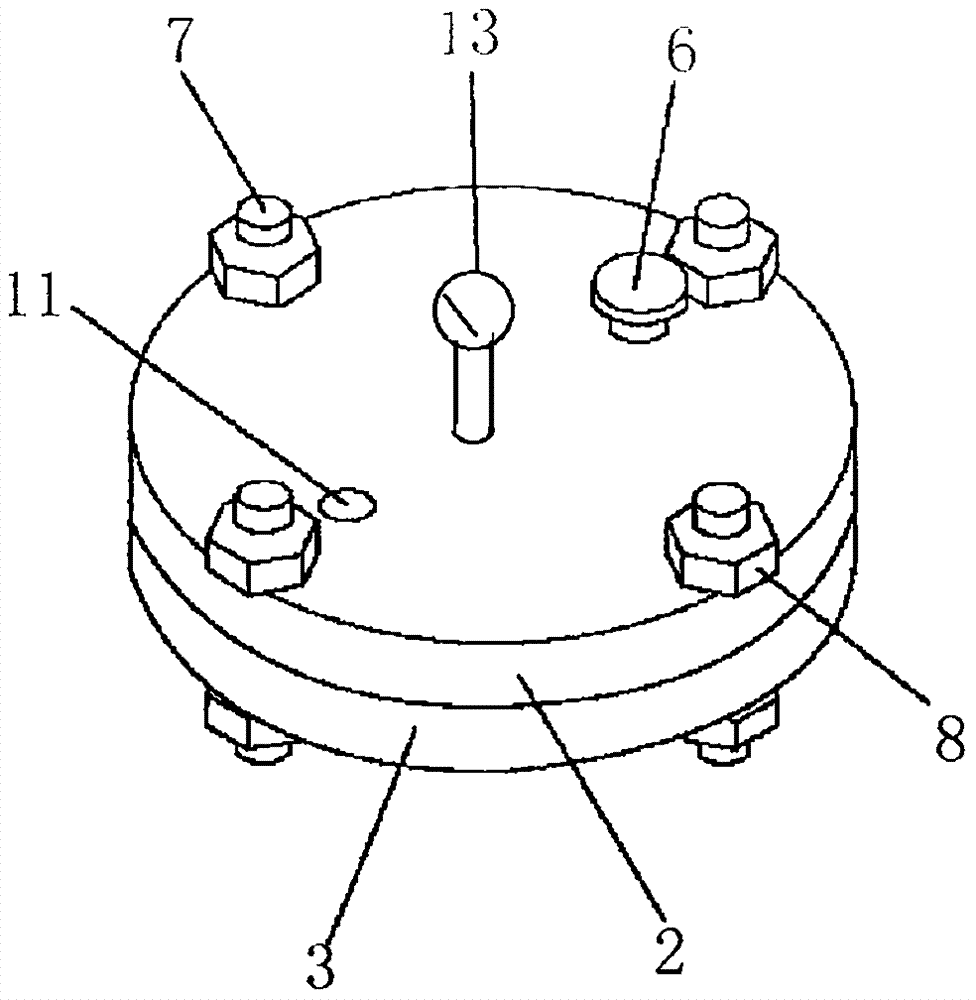

[0015] as attached figure 1 , 2 , shown in 3: the present invention is a kind of concrete pre-wet tank car, it is characterized in that, the concrete pre-wet tank on described tank car comprises the airtight pressure vessel tank body 4 that is supported on the chassis 1 of concrete mixer truck, in described tank A ring plate 3 is clamped around the discharge port at the rear end of the body, and a pressurized sealing cover 2 is covered on the ring plate. There are vent holes 10 and water injection holes 11 on the pressurized sealing cover, and an exhaust valve is connected on the vent hole. 6. A pressure sensor is provided inside the pressurized sealing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com