Fastening device

A technology of fastening device and fixing frame, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve problems such as difficulty in positioning items on the chute, and achieve the effects of smooth horizontal movement, improved efficiency, and fast positioning speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

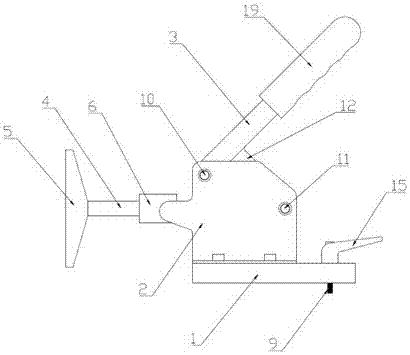

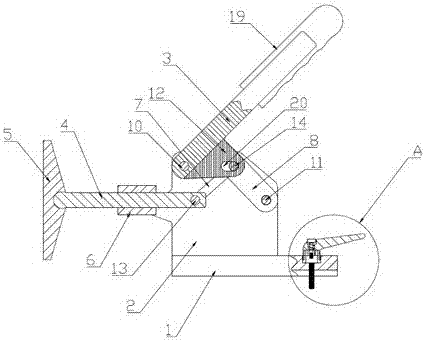

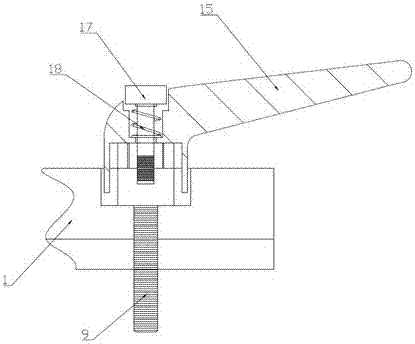

[0025] Example: such as Figure 1 to Figure 6 As shown, a fastening device includes a fixed seat 1, two fixed frames 2, a driving handle 3, a support rod 4, a support plate 5, a guide tube 6, a first driving piece 7, a second driving piece 8 and a locking Bolts 9, the two fixed frames 2 are vertically arranged on the upper surface of the fixed seat 1, the two fixed frames 2 are arranged oppositely, and the first fixed shaft 10 and the second fixed shaft 10 are arranged between the two fixed frames 2 Fixed shaft 11, the guide tube 6 is horizontally arranged on the left side of the two fixed frames 2, the right end of the support rod 4 passes through the guide tube 6 and stretches between the two fixed frames 2, the support rod 4 The left end is provided with a ball head, and the right side of the support plate 5 is provided with a ball bowl seat, and the ball head matches the ball bowl seat, and the ball head extends into the ball bowl seat. The lower end extends between the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com