Pipe bending machine

A technology of pipe bending machine and overturning motor, which is applied in the direction of unloading mandrels, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, low production efficiency and low degree of automation of workers, so as to reduce labor intensity of workers and improve the The effect of production efficiency and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

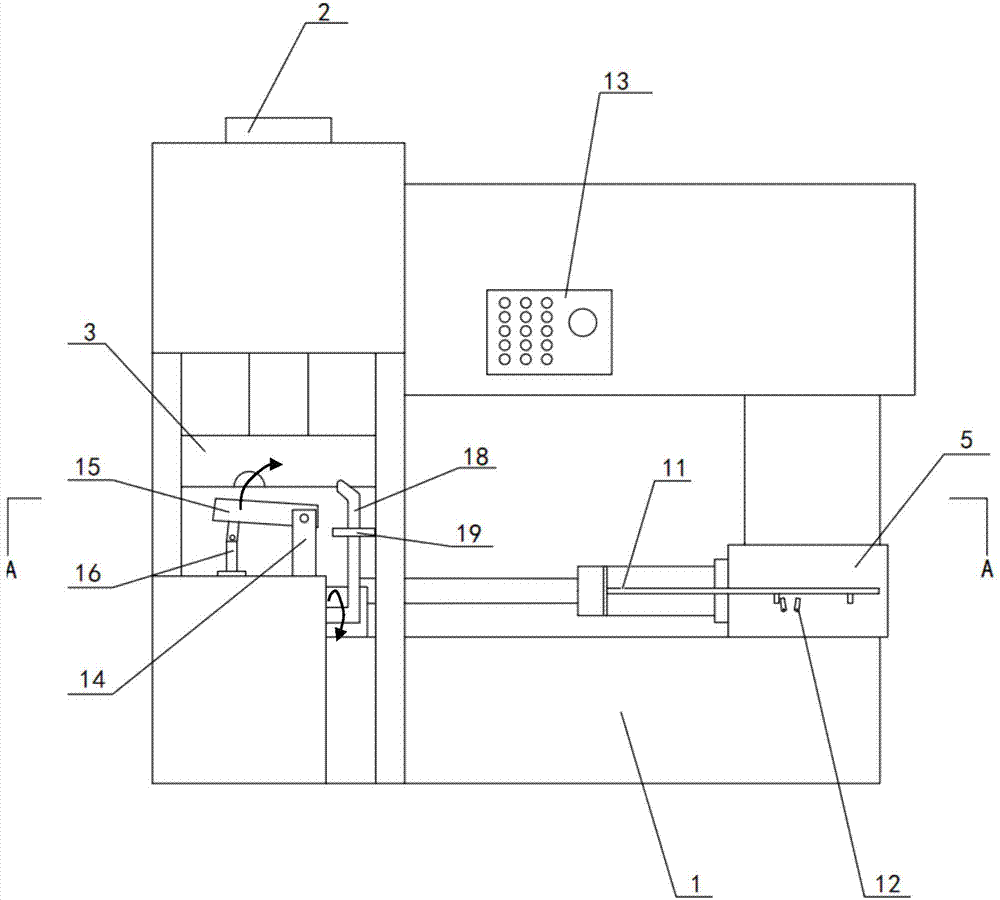

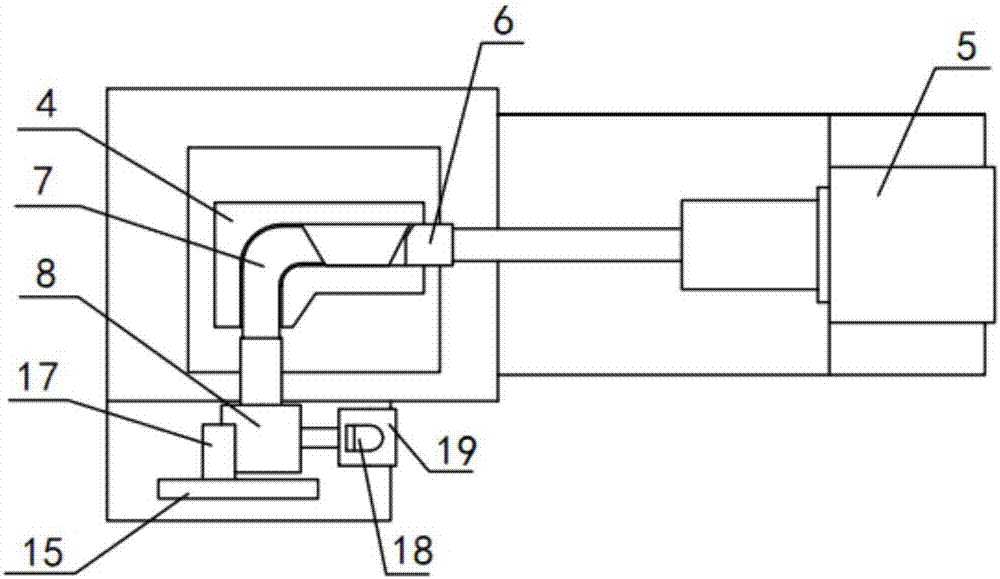

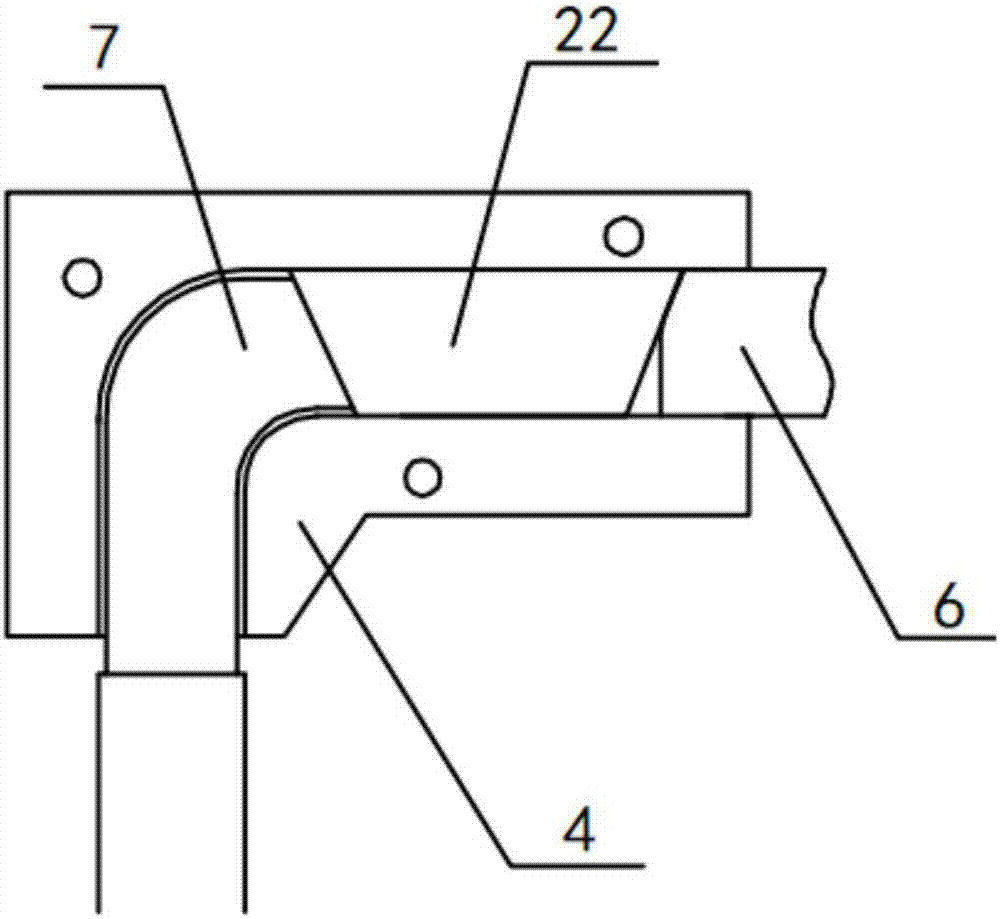

[0024] Such as Figure 1 to Figure 6 The shown pipe bending machine includes a bed 1, a vertically arranged down-press cylinder 2 is arranged on one side of the bed, an upper mold 3 is arranged at the lower end of the down-press cylinder, and a lower mold 4 is arranged directly below the upper mold 3, Forming grooves are respectively arranged on the mating surfaces of the upper mold 3 and the lower mold 4 . The upper mold can be pressed together with the lower mold under the drive of the lower pressure cylinder 2 to form a mold sleeve, and the other side of the bed 1 is horizontally provided with a push cylinder 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com