Motor and rotor thereof

A rotor and rotor shaft technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problem of motor miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

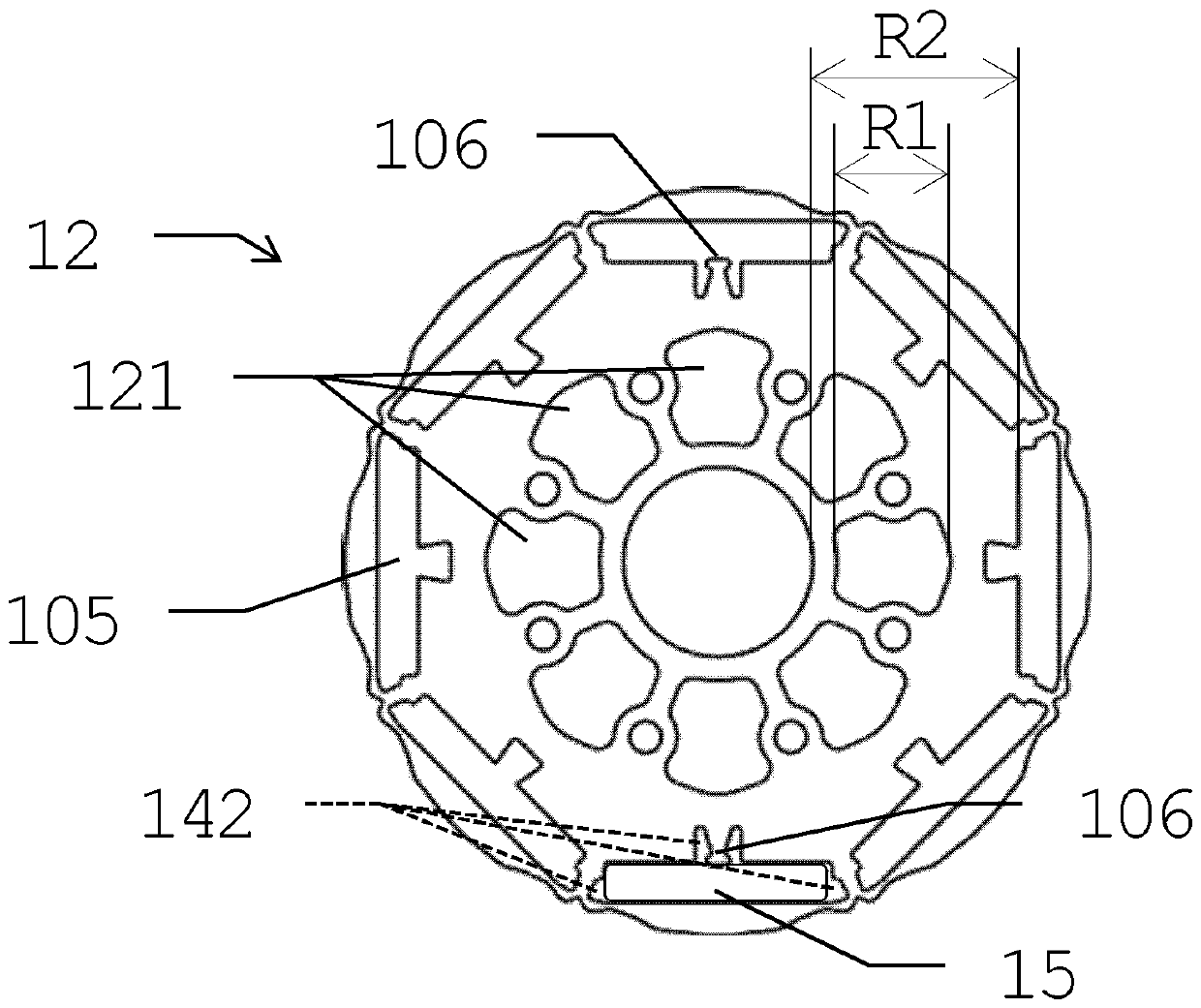

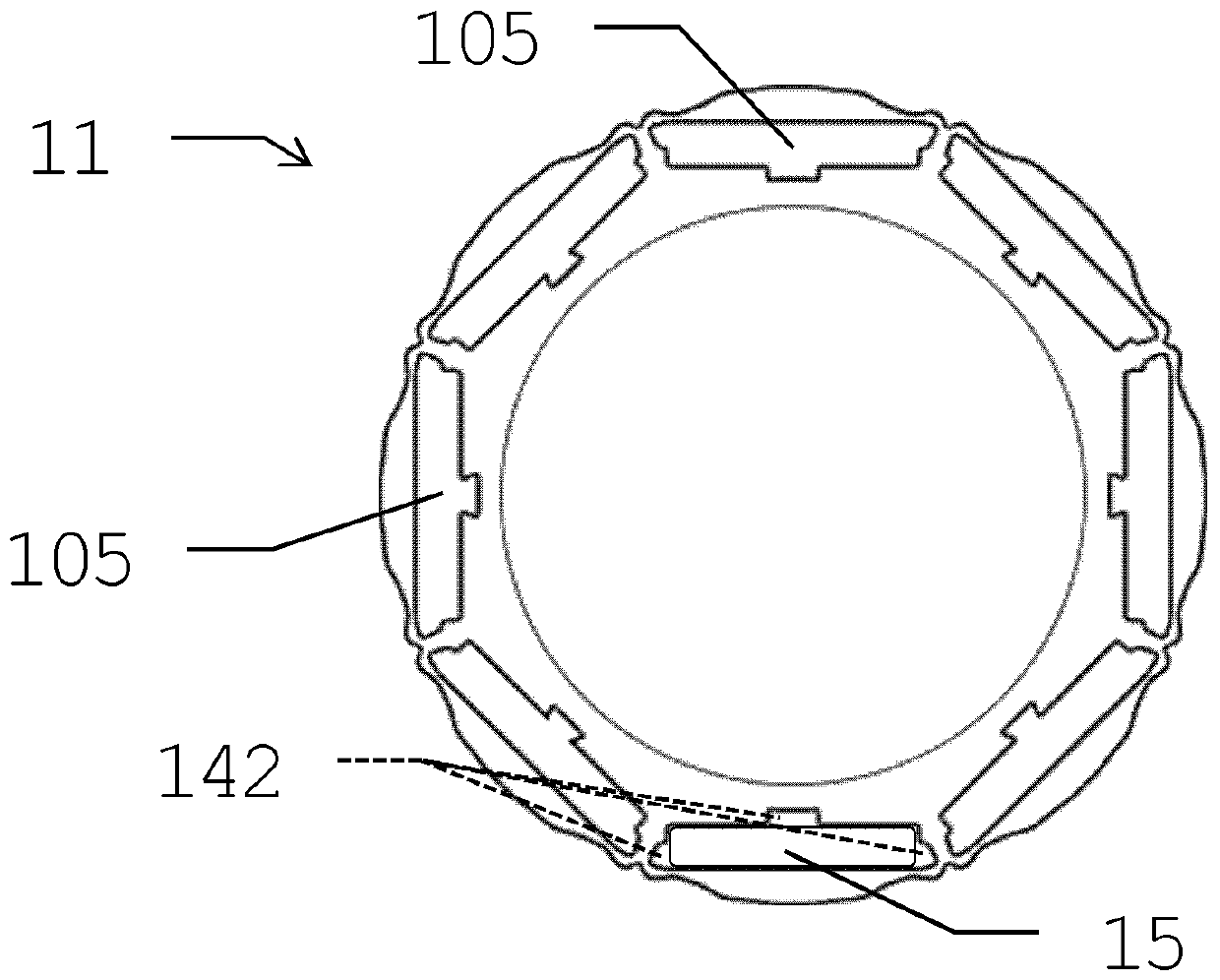

[0016] The specific implementation manner of the present application will be described in detail below in conjunction with the accompanying drawings.

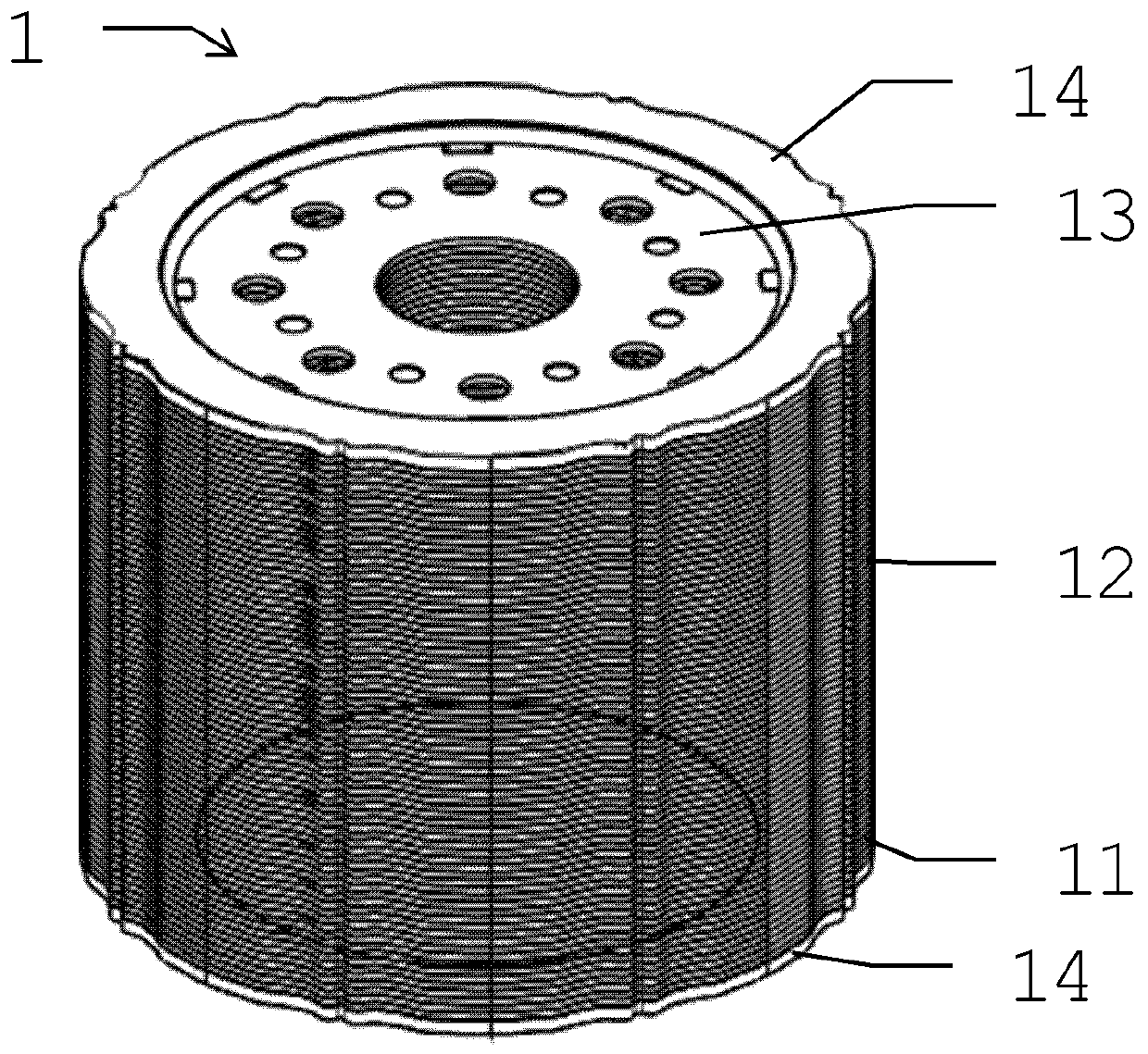

[0017] see figure 1 As shown, a motor 100 according to a specific embodiment of the present application includes a housing 3 , a stator 4 , a rotor 10 , and a first bearing 51 and a second bearing 52 . The stator 4 is fixed on the housing 3 , and the first bearing 51 and the second bearing 52 are installed between the housing 3 and the rotor 10 . In the specific embodiment shown in the figure, both the first bearing 51 and the second bearing 52 are ball bearings.

[0018] The casing 3 includes a base body 31 and a cover body 32 , the base body 31 is stamped from a sheet metal to form a container with an opening at the top, and at least most of the core body 1 is located in the base body 31 . in such as figure 1 In the specific embodiment shown, all iron cores of the stator 4 and the rotor 10 are housed in the seat body 31 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com