Automatic coal flow dust control spraying method and system

A technology of automatic spraying and coal flow, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of time-consuming and labor-intensive, and short dust suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

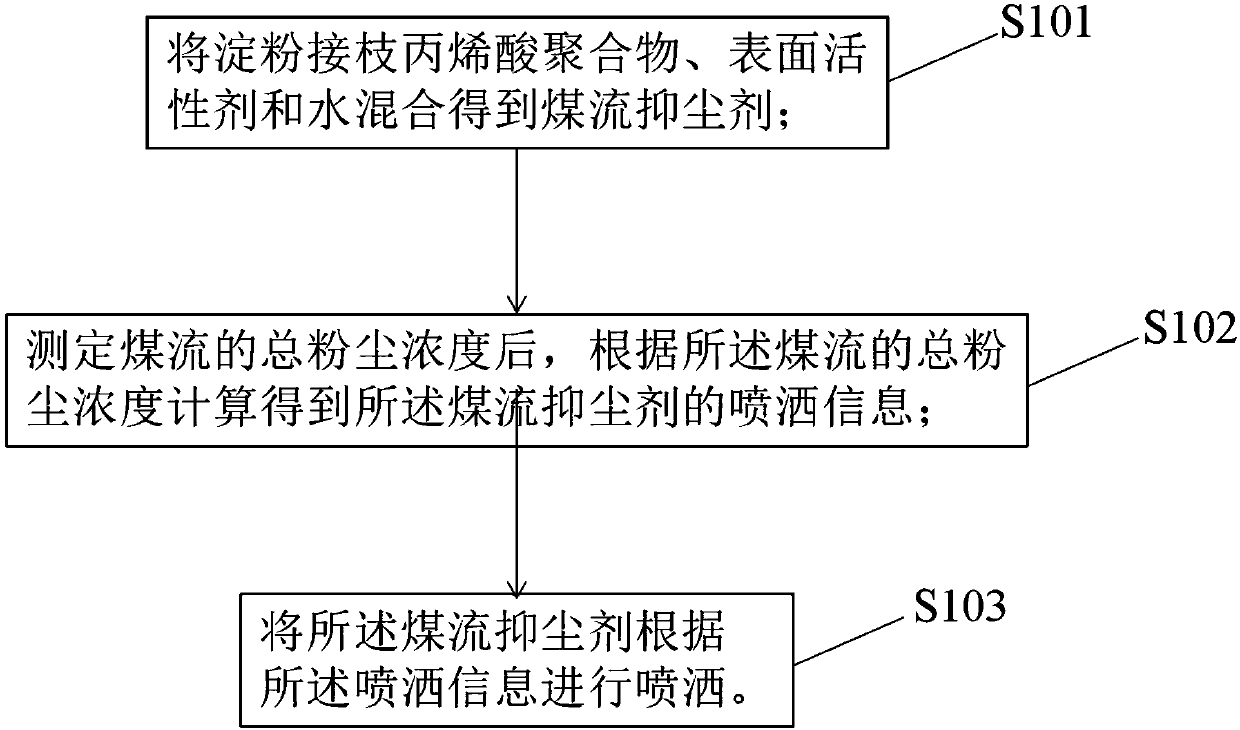

[0041] see figure 1 , figure 1 It is a flow chart of an automatic spraying method for coal flow dust suppression. Embodiment 1 of the present invention discloses an automatic spraying method for coal flow dust suppression, including: S101: mixing starch-grafted acrylic acid polymer, surfactant and water to obtain a coal flow dust suppressant; S102: measuring the total dust of coal flow After the concentration is calculated, the spraying information of the coal flow dust suppressant is calculated according to the total dust concentration of the coal flow; S103: Spray the coal flow dust suppressant according to the spraying information.

Embodiment 2

[0043] see figure 1 , figure 1 It is a flow chart of an automatic spraying method for coal flow dust suppression. Embodiment 1 of the present invention discloses an automatic spraying method for coal flow dust suppression, including: S101: mixing starch-grafted acrylic acid polymer, surfactant and water to obtain a coal flow dust suppressant; S102: measuring the total dust of coal flow After the concentration is calculated, the spraying information of the coal flow dust suppressant is calculated according to the total dust concentration of the coal flow; S103: Spray the coal flow dust suppressant according to the spraying information.

[0044] Further, according to parts by weight, the coal flow dust suppressant includes:

[0045] 1.0-3.0 parts of starch grafted acrylic acid polymer;

[0046] Surfactant 0.02-0.06 part;

[0047] 100 parts of water.

[0048] Further, the preparation method of starch grafted acrylic acid polymer is as follows:

[0049] S201: gelatinizing st...

Embodiment 3

[0066] see figure 2 , figure 2 It is a structural diagram of the coal flow dust suppression automatic spraying system. The coal flow dust suppression automatic spraying system of embodiment 3 includes: a dispensing device, a control device, a spraying device and a dust concentration monitoring device; the dispensing device is used to polymerize starch grafted acrylic acid Coal flow dust suppressant is obtained by configuring material, surfactant and water; the control device 5 is connected with the dispensing device and the spraying device respectively; the dust concentration monitoring device 17 is connected with the control device 5, so that the control device 5 obtains the coal flow of the dust concentration monitoring device The total dust concentration of the coal flow; the dispensing device is connected to the spraying device pipeline, so that the control device 5 calculates the spraying information of the coal flow dust suppressant according to the total dust concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com