Sheet clamping and transporting device

A technology of conveying device and pushing device, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of loss of enterprises, inability to process thin plates, and increase production costs of enterprises, and achieves a high degree of automation, simple device structure, and guaranteed compression. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

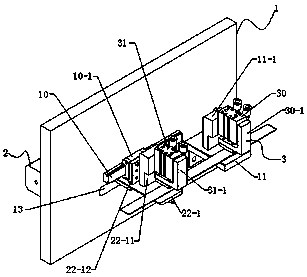

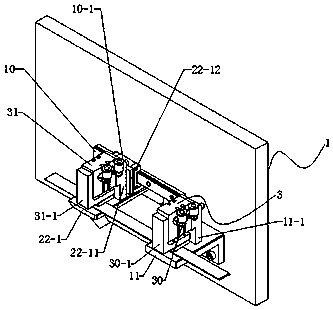

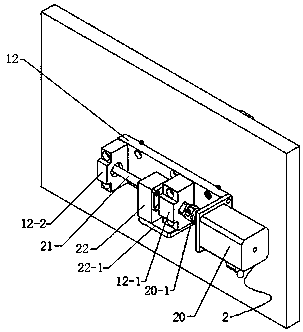

[0018] see Figure 1-3 , a thin plate clamping conveying device, including a fixed plate 1, a push device 2 and a pneumatic clamping device 3, the front surface of the fixed plate 1 is provided with a slide rail bar 10 and a support plate 11, and the slide rail bar 10 is welded on the fixed plate 10 Above, the support plate 11 is fixed on the fixed plate 1 by bolts, a sliding block 10-1 is provided on the slide rail bar 10, a rectangular groove 13 is provided on the fixed plate 1 below the slide rail bar 10, and a rectangular groove 13 is provided on the fixed plate 1 rear surface. The L-shaped plate 12, and the L-shaped plate 12 is welded on the fixed plate 1, the L-shaped plate 12 is provided with a support 12-1 and a support 2 12-2, and the support 12-1 and the support 2 12 -2 is fixed on the L-shaped plate 12 by bolts, the pushing device 2 includes a motor 20, a lead screw 21 and a moving seat 22, the motor 20 is fixed on the bottom plate of the L-shaped plate 1, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com