Powder accurate-weighing measurement feeding machine

A metering feeding and feeding technology, applied in the field of machinery, can solve the problems of feeding discontinuity, shaking of weighing hopper, affecting measurement accuracy, etc., achieve the best resistance to mechanical vibration interference, stable feeding, and ensure continuity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

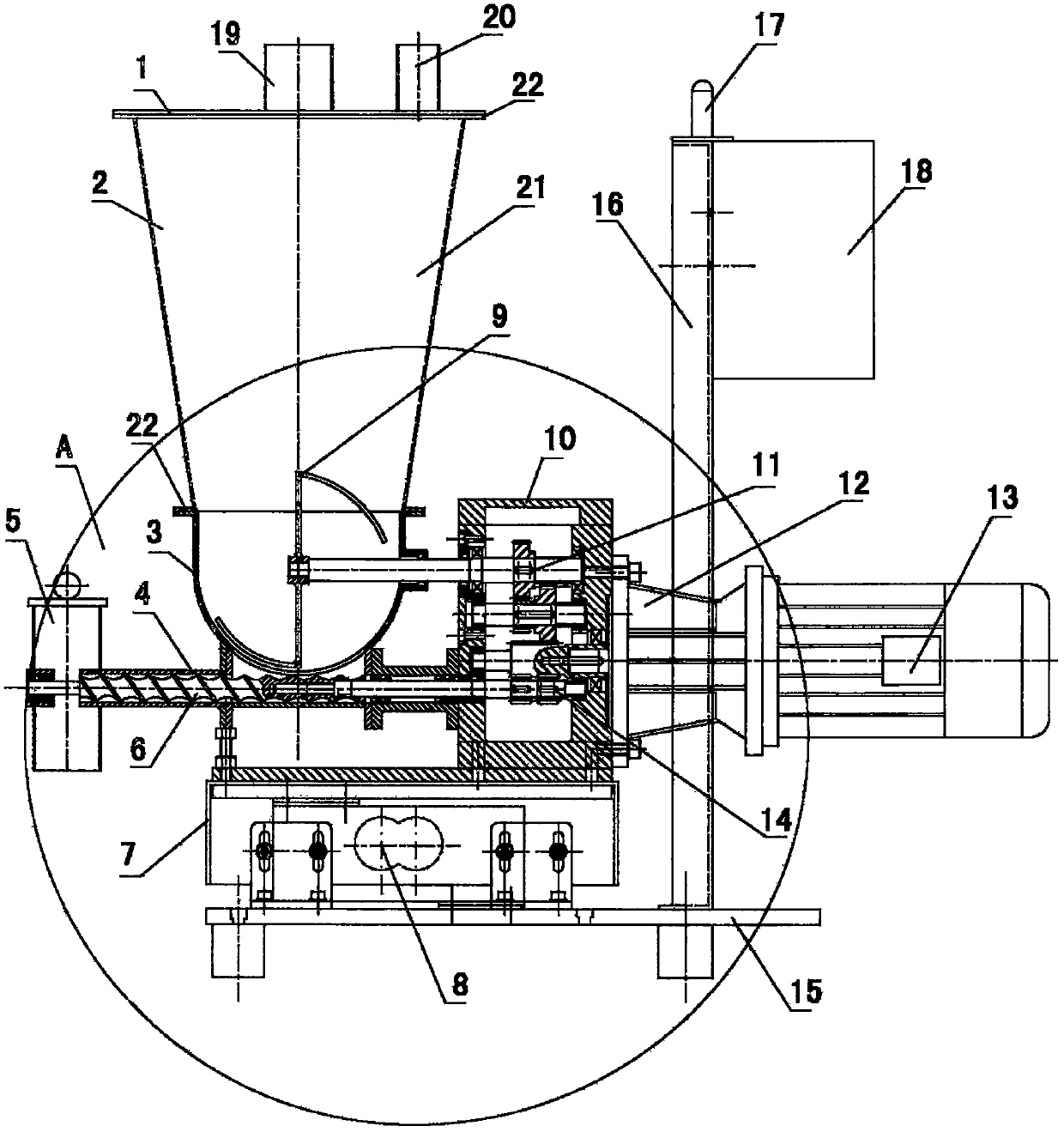

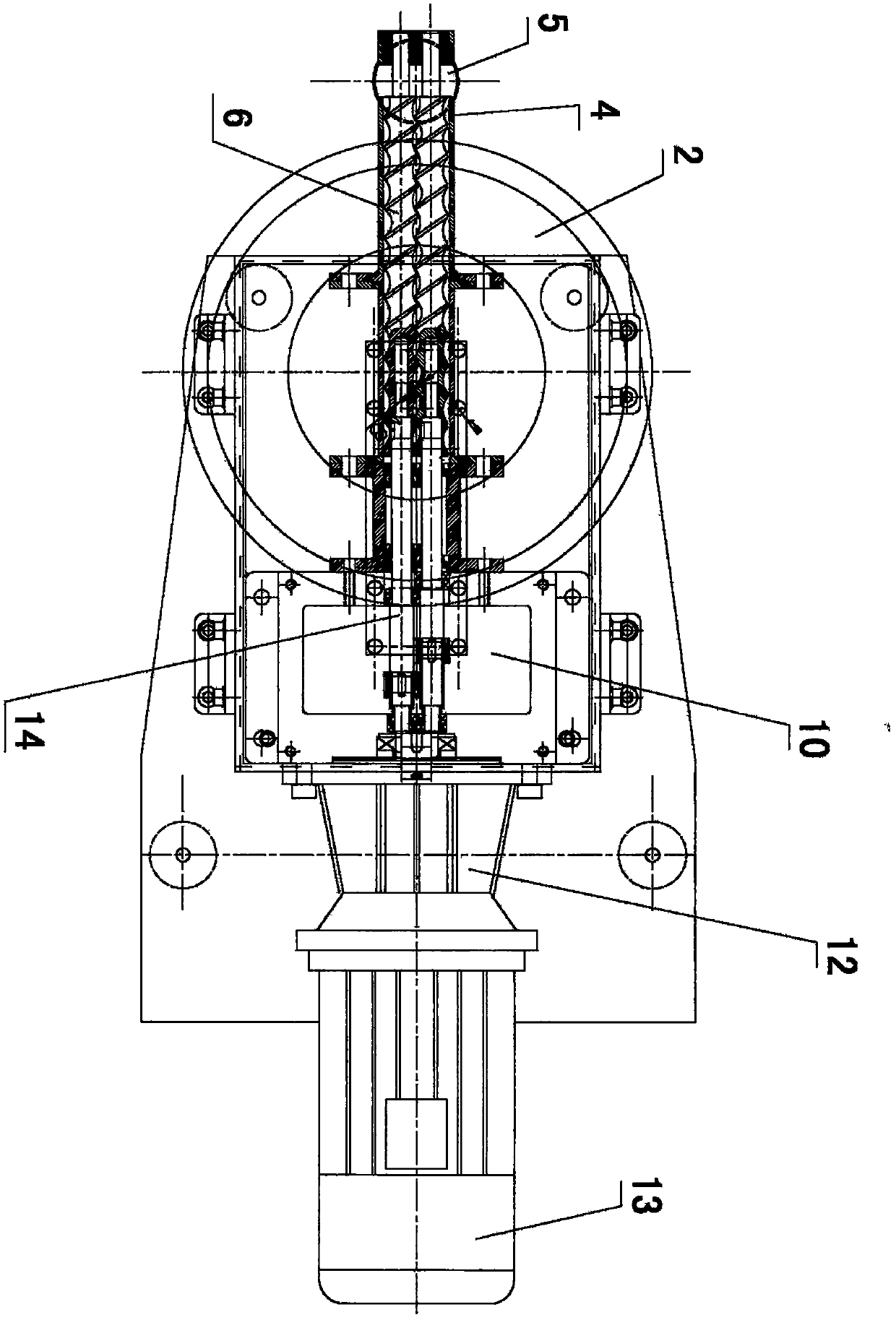

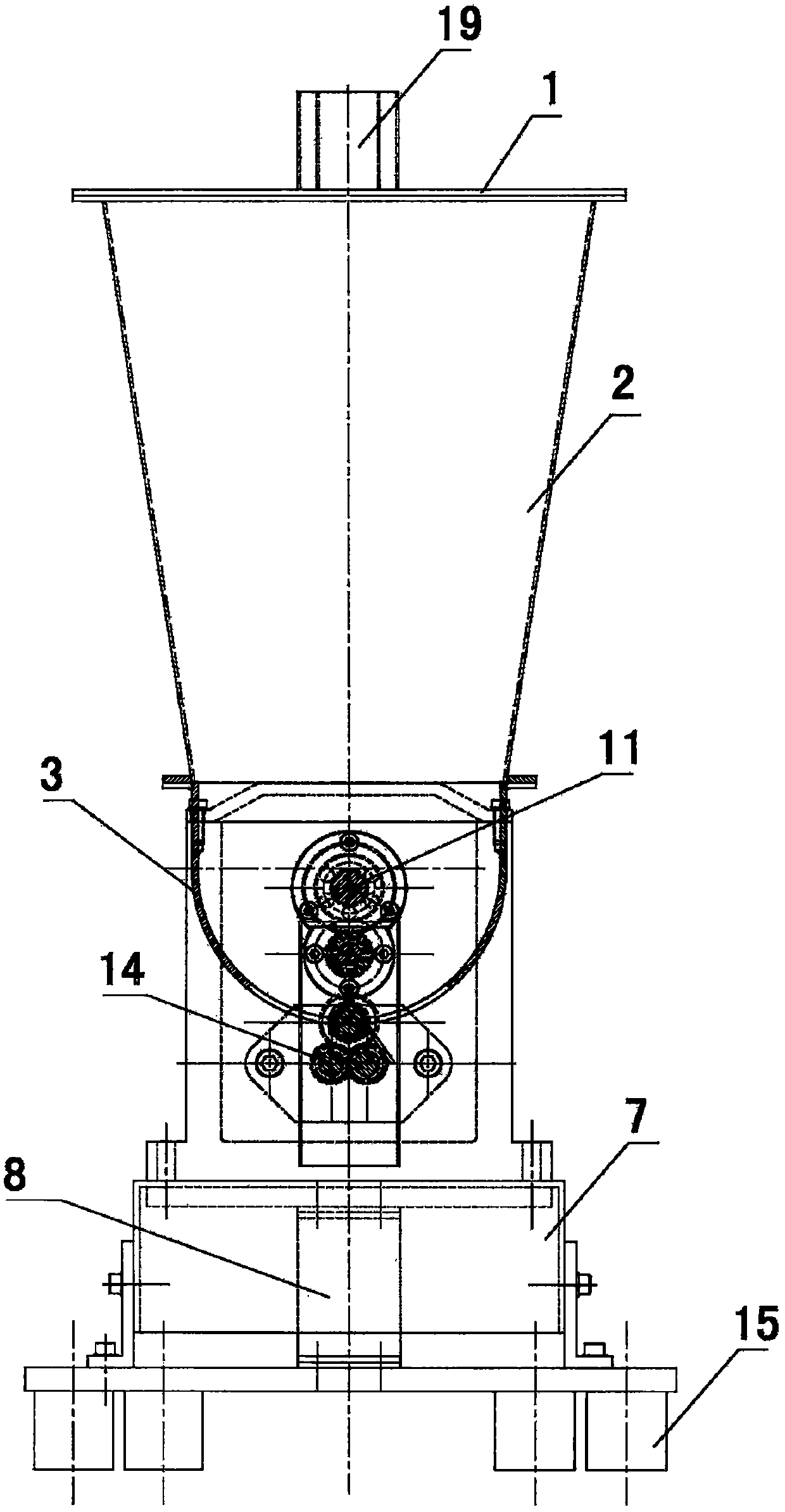

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is a powder feeder with accurate weighing and metering, comprising a weighing hopper 2, a spherical bucket 3, a feeding cylinder 4, a container 5, a feeding twin screw 6, a gear box 10, a reduction motor 13, The weighing platform 7 and the bellows load cell 8 are characterized in that: the weighing hopper 2 includes a cover plate 1 and a cone 21, the feeding port 19 of the weighing hopper 2 is arranged at the center of the cover plate 1, and one part of the cover plate 1 Ventilation holes 20 are provided on the side, the upper part of the cone 21 is connected with the cover plate 1 through the clamp 22, the lower part of the cone 21 is connected with the upper part of the spherical bucket 3 through the clamp 22, and the lower part of the spherical bucket 3 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com