Comprehensive tire abrasion testing machine

A comprehensive test and tire technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve problems such as the inability to adapt to high-speed tire testing, the failure of flat belt testing machines to be widely used, and the easy fatigue damage of steel belts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

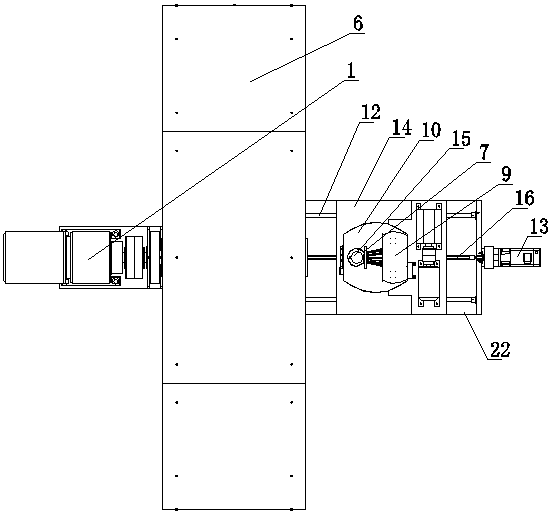

[0017] Such as Figure 1-4 The tire wear comprehensive testing machine shown is provided with a frame 6, on which a rotating shaft 2 is installed via a bearing, and a power source 1 is provided on the frame behind the rotating shaft 2, and the power source 1 is connected to the rotating shaft 2 through a transmission device ,From figure 1 It can be seen from the figure that the power source 1 is a servo motor, the output shaft of the servo motor is provided with a driving pulley, the rotating shaft 2 at the rear side of the frame is provided with a driven pulley, and there is a drive pulley between the driving pulley and the driven pulley Drive belt; the rotating shaft on the front side of the frame 6 is fixedly connected with a turntable 4, and the turntable 4 is fixed with a drum 5, and the front side of the drum 5 is provided with a circular test groove 3 coaxial with the rotating shaft 2; The frame on the side is provided with a side deflection table, and the side deflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com