Steel-plastic composite support assembly for automobile instrument panel and automobile

A hybrid vehicle and bracket assembly technology, which is applied to instrument panels, upper structure subassemblies, vehicle components, etc., can solve problems such as increased maintenance costs, affecting the tolerance level of the instrument panel bracket assembly, production quality stability, and complex structures. , to achieve the effect of increasing structural stiffness, improving NVH performance, and improving modal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

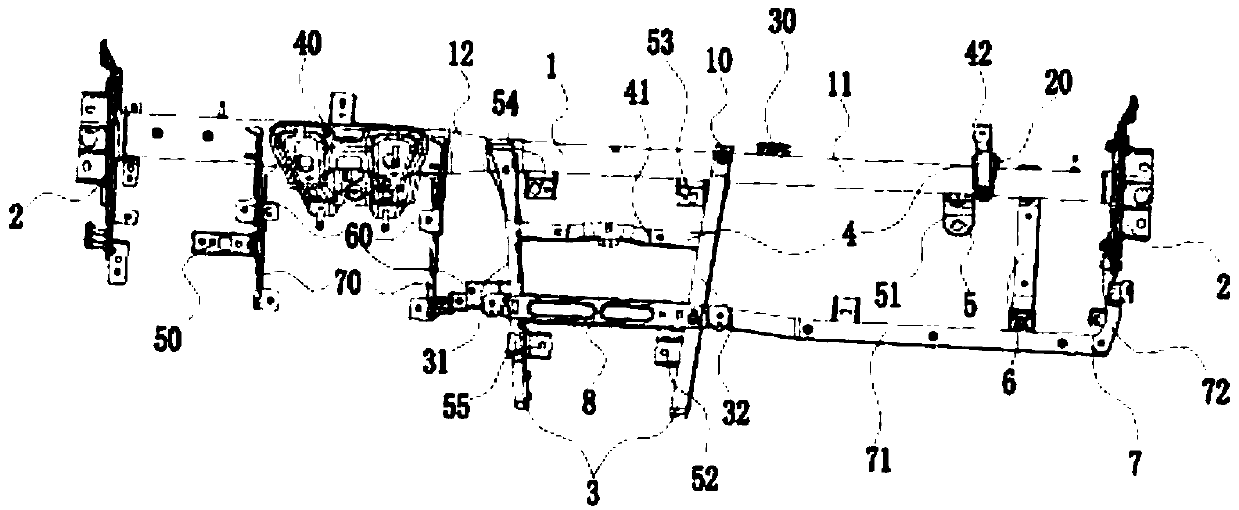

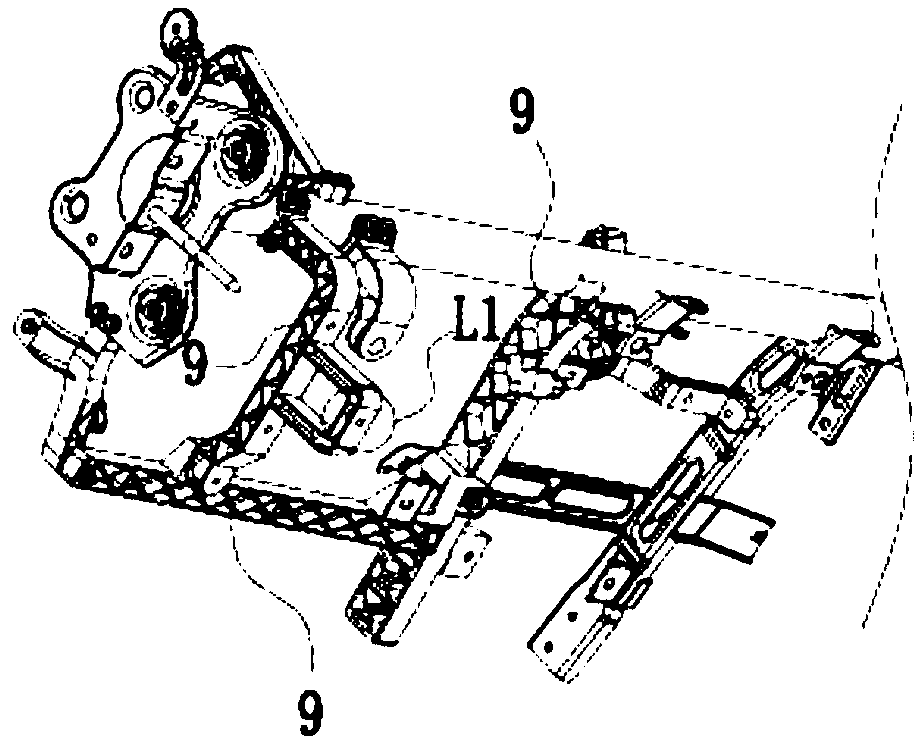

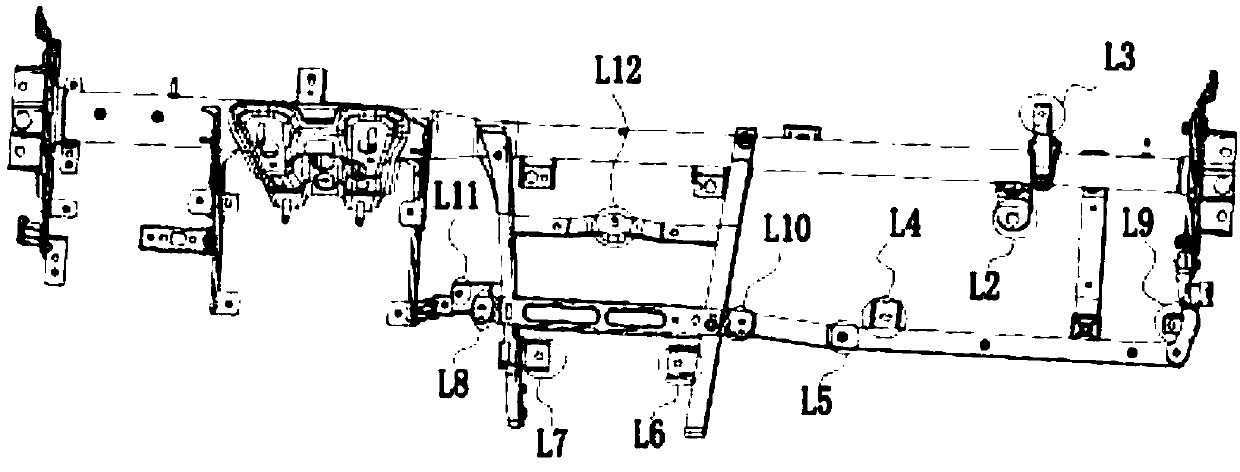

[0033] The invention discloses a steel-plastic hybrid automobile instrument panel bracket assembly, as attached figure 1 As shown, it includes a steel beam 1, the beam 1 includes a right pipe column 11 and a left pipe column 12, the two ends of the beam 1 are respectively provided with vehicle body mounting brackets 2, and the steel-plastic hybrid vehicle instrument The board bracket assembly also includes at least the connecting bracket 3 for connecting the floor, the IP bracket 4 for installing the instrument panel (IP), the air conditioning bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com