Box culvert transport vehicle and box culvert construction method

A technology for transport vehicles and box culverts, applied in the field of transport vehicles, can solve problems such as hidden dangers of operation safety, inability to work, and large weather effects, and achieve the effects of ensuring construction progress, being conducive to protection, and high operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

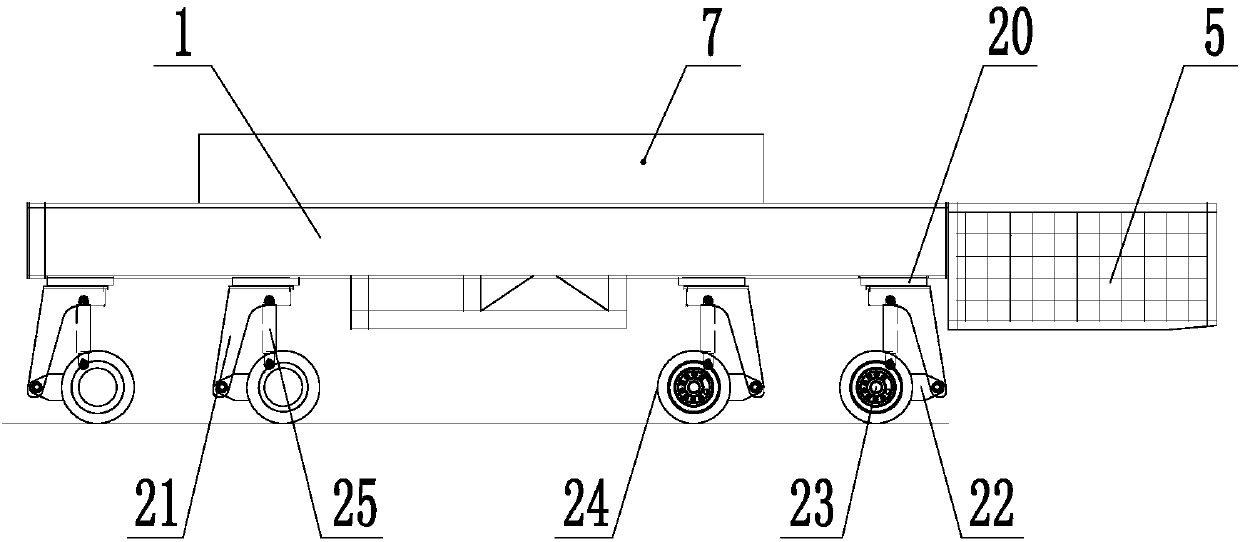

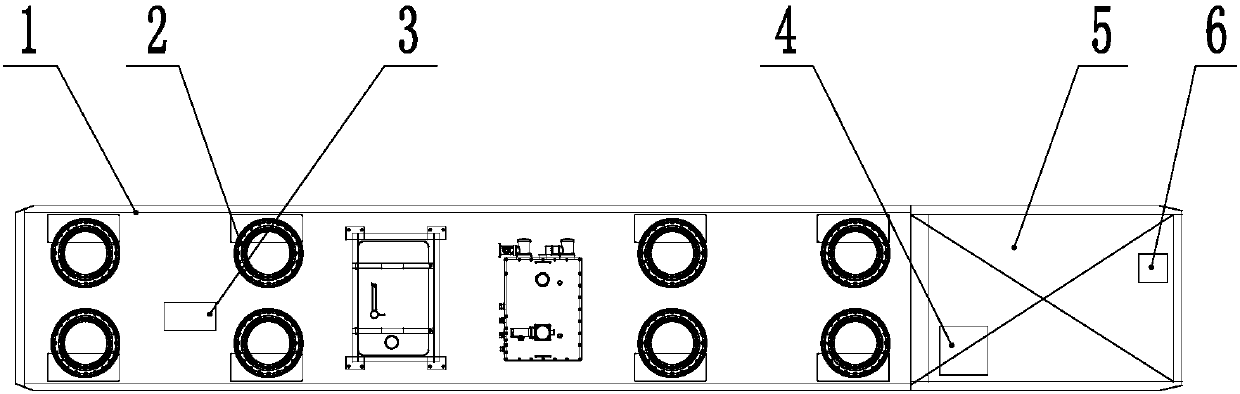

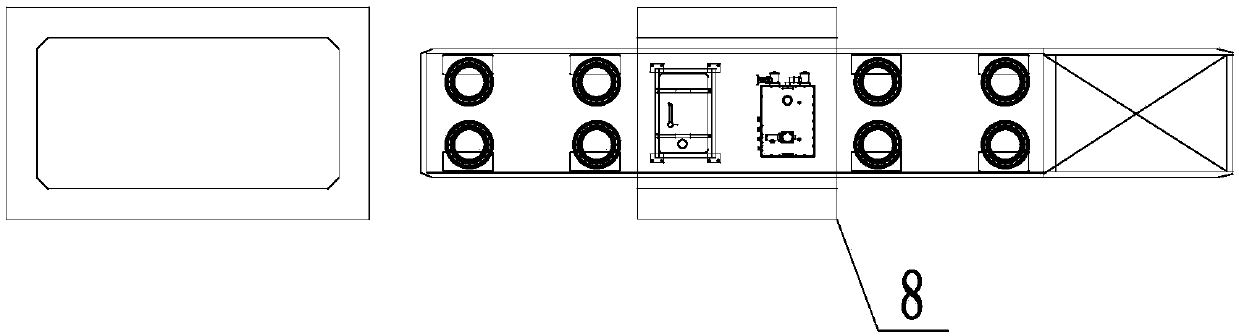

[0041] Such as figure 1 , 2 A box culvert transport vehicle shown includes a vehicle frame 1 , a walking system 2 connected to the lower part of the vehicle frame 1 , a braking system 3 , a hydraulic system 4 , a power system 5 and an electrical system 6 . Among them: the brake system 3 is used for driving or parking brake; the hydraulic system 4 and the power system 5 are arranged at one end of the frame 1, and are respectively used to control the lifting and steering of the walking system 2 and provide power for the whole vehicle; System 6 is used to provide lighting and vehicle control; the vehicle can be controlled by wireless remote control.

[0042] In this embodiment: the walking system 2 includes a plurality of steering mechanisms 20, independent suspension mechanisms connected to the steering mechanisms 20, and wheels 24 connected to the independen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com